Automatic feeding device with robots

A technology of automatic feeding and robotics, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of not having high speed, high acceleration operation, no intelligent identification and judgment function, and limited industrial application range, so as to eliminate product defects Efficiency increase, low cost, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

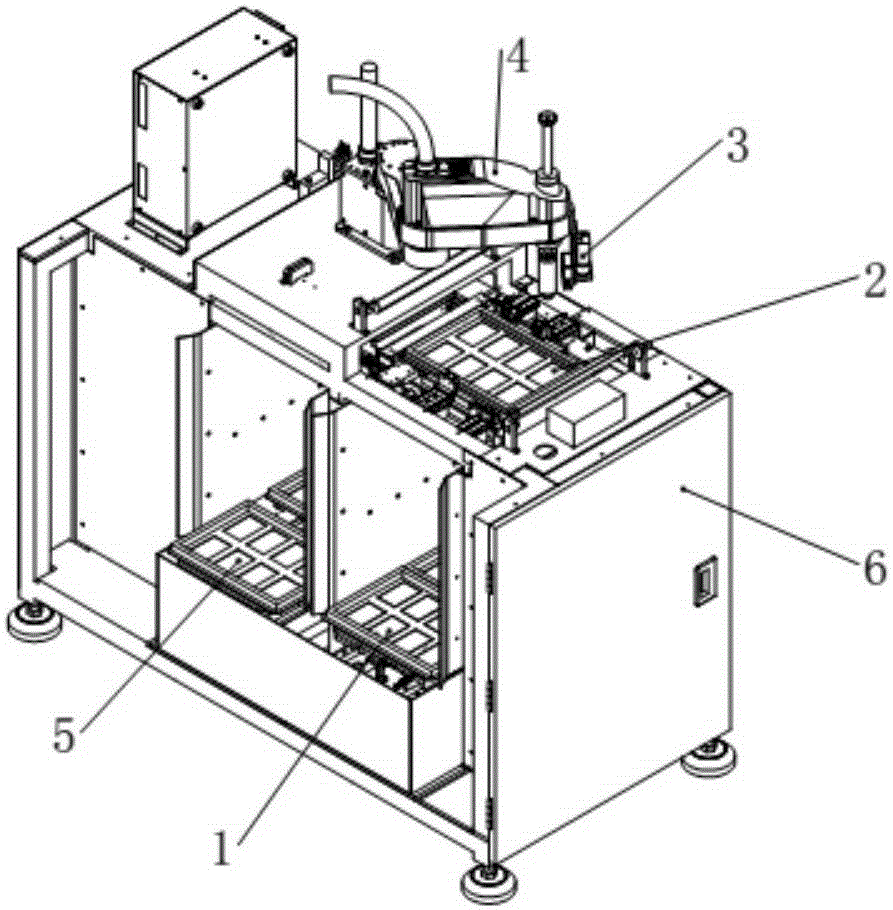

[0046] like figure 1 and figure 2 Shown, a kind of automatic feeding equipment that uses robot 41, comprises platform 6, is arranged on the PLC control system on platform 6, and is arranged on platform 6 and is connected with the feeding system of PLC control system, and platform 6 is provided with Safety cover 8, feeding system includes:

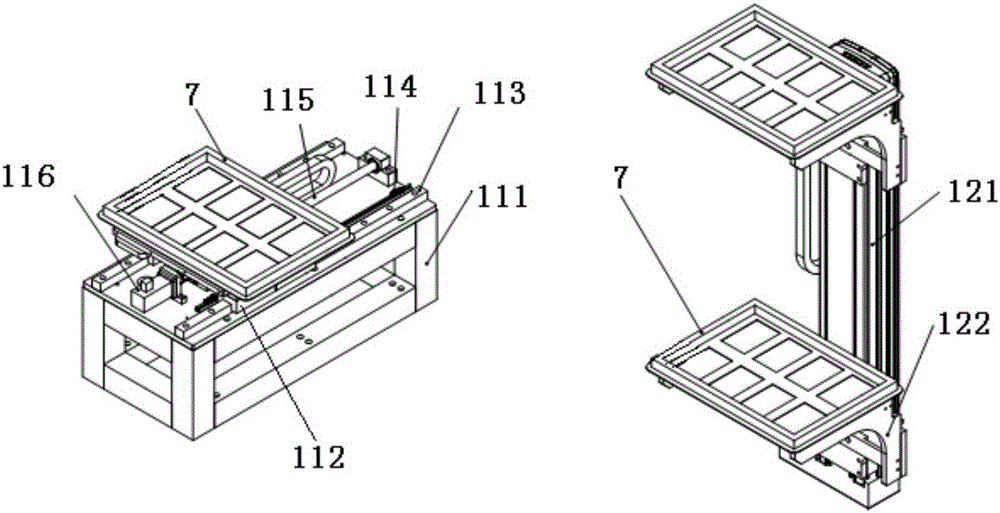

[0047] Feeding mechanism 1, its structure is as image 3 As shown: it is composed of the first y-direction conveying device 11 moving forward and backward along the y-axis and the first z-direction conveying device 12 moving up and down along the z-axis; the first y-direction conveying device 11 includes a first fixing frame 111, and is set The first pallet platform 112, the first sensor 114, the first ball screw 115 and the servo motor 116 on the first fixed frame 111, the first linear slide rail 113 along the y-axis direction is provided on the first fixed frame 111, The first pallet platform 112 is arranged on the first linear slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com