Device for guiding at least one line of an articulated arm robot and articulated arm robot

An articulating arm, manipulator technology, applied in mechanical equipment, manipulators, layouts using gravity loading loops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

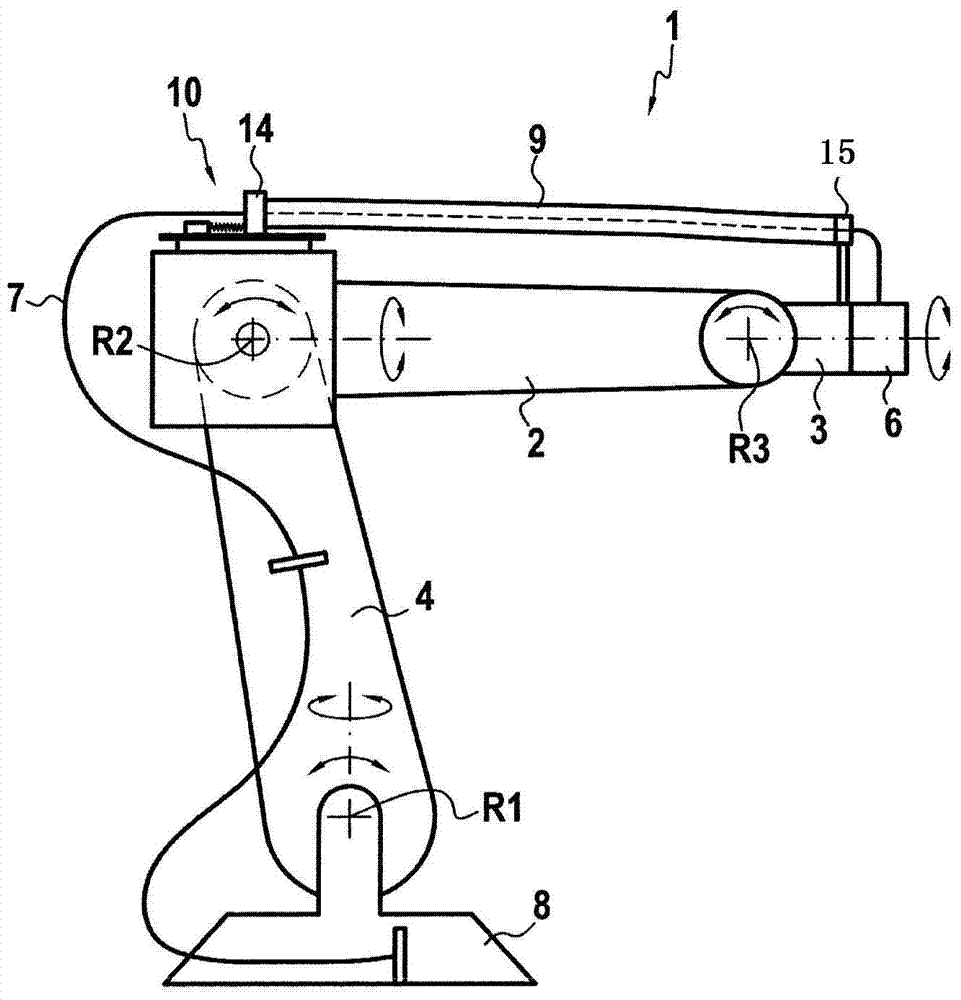

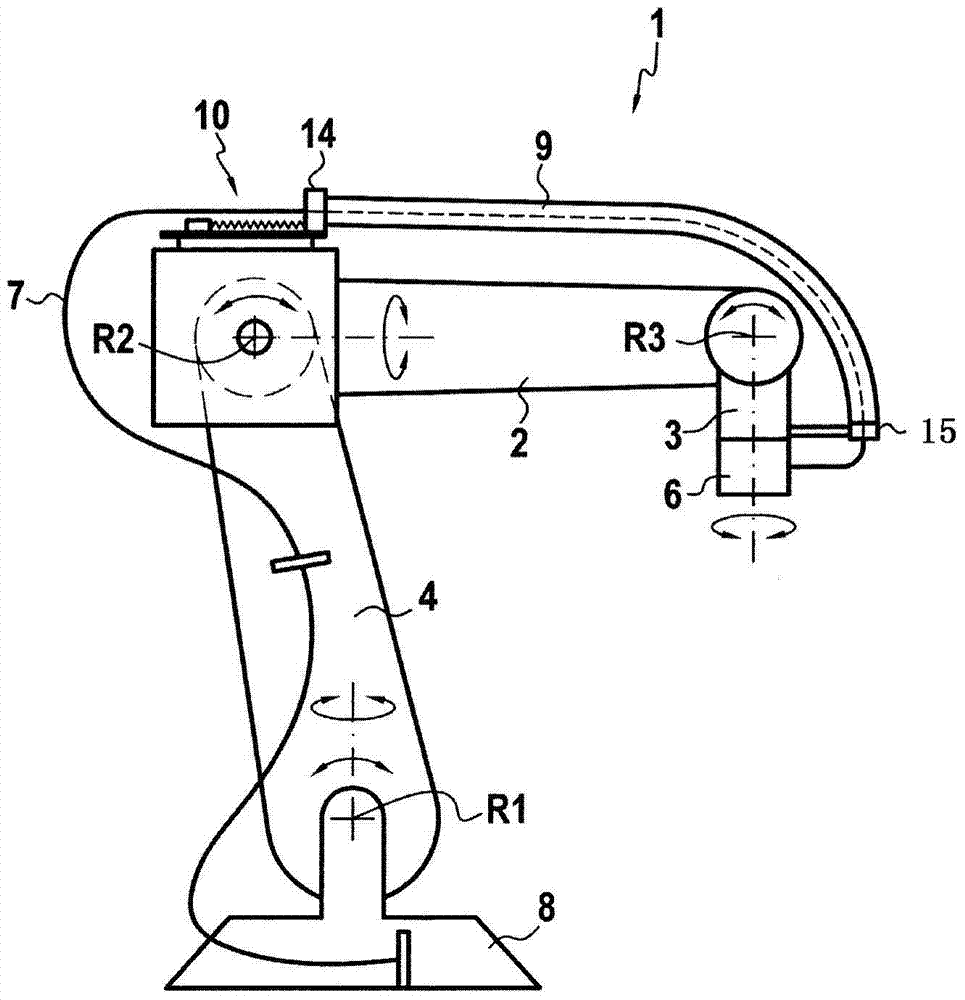

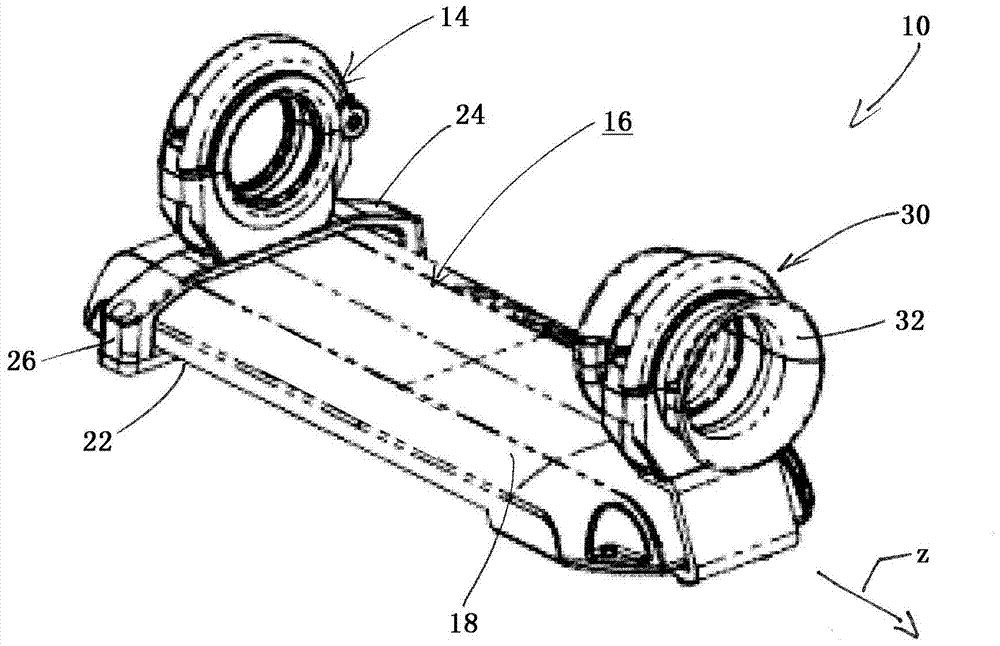

[0046] Figure 1A , 1B The articulated arm manipulator is shown in two different positions. The articulated arm manipulator 1 refers to, for example, a multi-axis industrial manipulator, especially a six-axis industrial manipulator or a medical manipulator. The articulated arm manipulator has a base 8 , a first segment called rocker arm 4 , which is connected to the base 8 via a first articulated connection R1 . The rocker arm 4 can pivot about the first articulated connection R1 in a manner about a horizontal axis. In addition, the rocker arm 4 can generally be pivoted relative to the base 8 about a vertical axis. The rocker arm 4 extends upwards substantially in a vertical direction. On the second articulated connection R2, a second segment, commonly referred to as the robotic arm part 2, is connected to the rocker arm 4 in a pivotable movement about the so-called "axis 3". Finally, the manipulator hand 3 as the third segment is connected to the second segment 2 via a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com