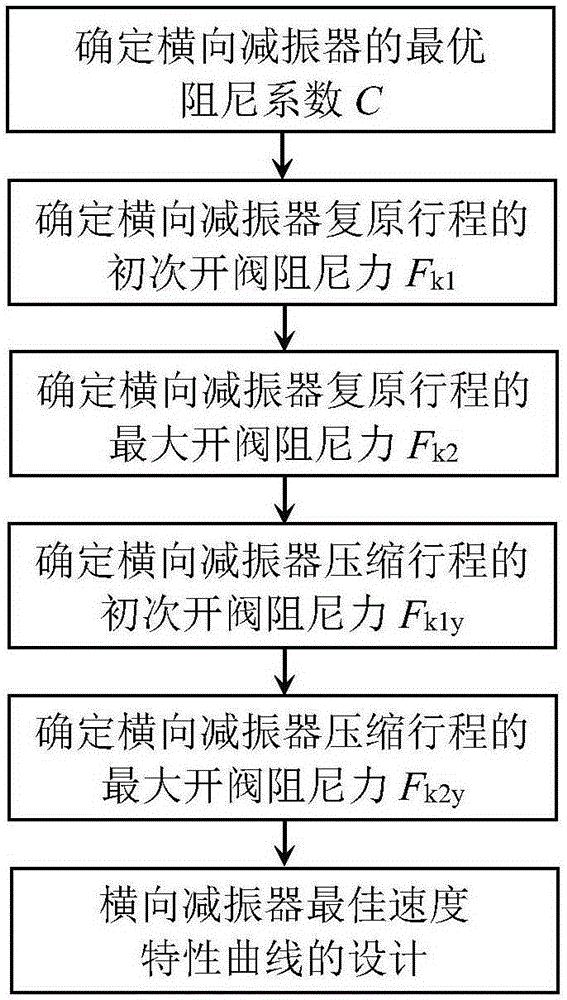

Freight car front wheel shimmy system lateral damper optimum speed characteristics design method

A technology for lateral shock absorbers and front wheels of trucks, which is applied in the fields of instruments, calculations, special data processing applications, etc., can solve the problems of difficult matching of lateral shock absorbers to achieve the best damping, and no reliable design methods are given.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] specific implementation plan

[0054] The present invention will be further described in detail through an embodiment below.

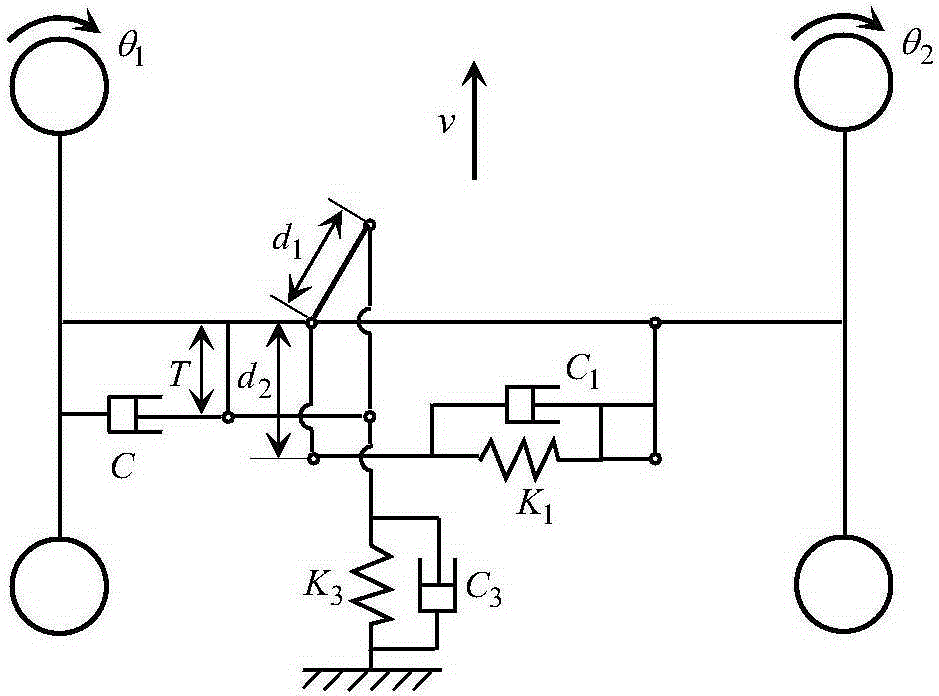

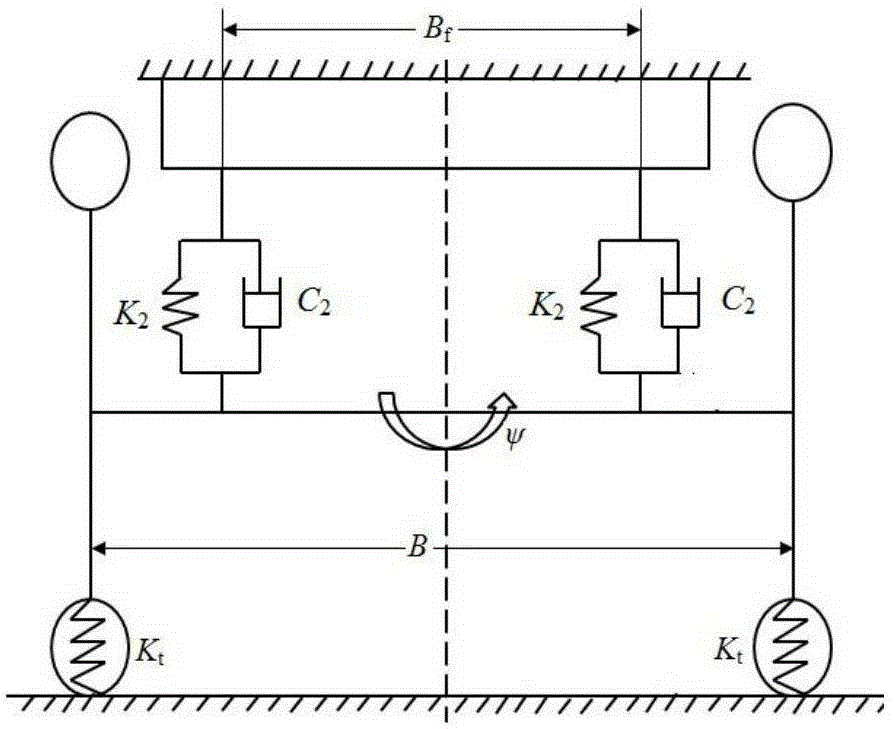

[0055] Equivalent angular stiffness K of the steering tie rod of a truck 1 =49.1kN.m / rad, the equivalent angular stiffness K of the steering column of the front wheel steering system 3 =30.41kN.m / rad; Steering tie rod equivalent angular damping C 1 =30N.m.s / rad, steering column equivalent angular damping C 3 =70N.m.s / rad; Suspension system vertical stiffness K 2 =6.06kN.s / m, shock absorber equivalent damping coefficient C 2 =1.72kN.s / m; tire vertical stiffness K t= 850kN / m, lateral stiffness ρ = 190kN / m, cornering stiffness k = 94kN.m / rad, mechanical drag moment β = 0.06m; moment of inertia of left and right front wheels around kingpin I = 20kg.m 2 , the moment of inertia I of the wheel around its own axis w =12.96kg.m 2 , the moment of inertia of the front axle around the roll axis J=31.88kg.m 2 ;The arm length d of the steering knuckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com