Horizontal tension tester's fixture for round wire concentric-lay-stranded overhead conductors

A horizontal tensile test, overhead wire technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of heavy weight, complex chuck structure, influence, etc., to increase the contact area, reduce broken strands or broken wires the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

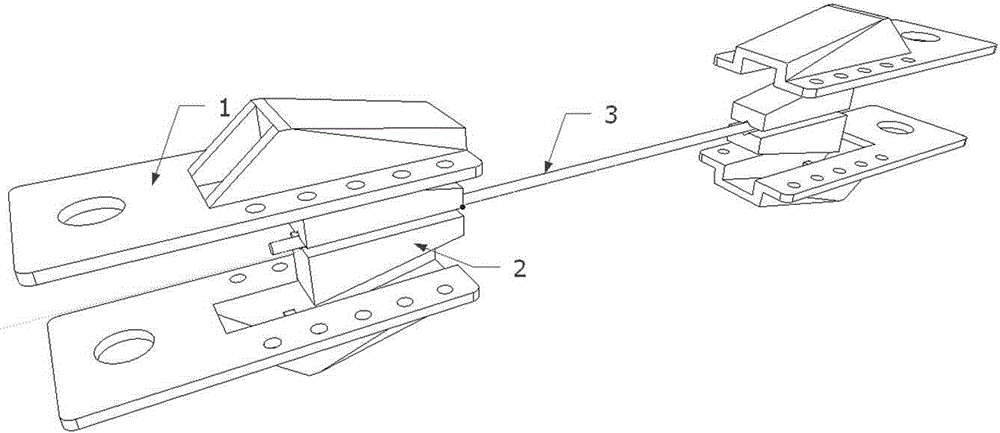

[0021] see figure 1 , a round wire concentric stranded overhead wire clamp used for a horizontal tensile testing machine includes a pair of clamping mechanisms with the same specifications, and each pair of clamping mechanisms includes a pair of clamping blocks and a pair of clamp shells.

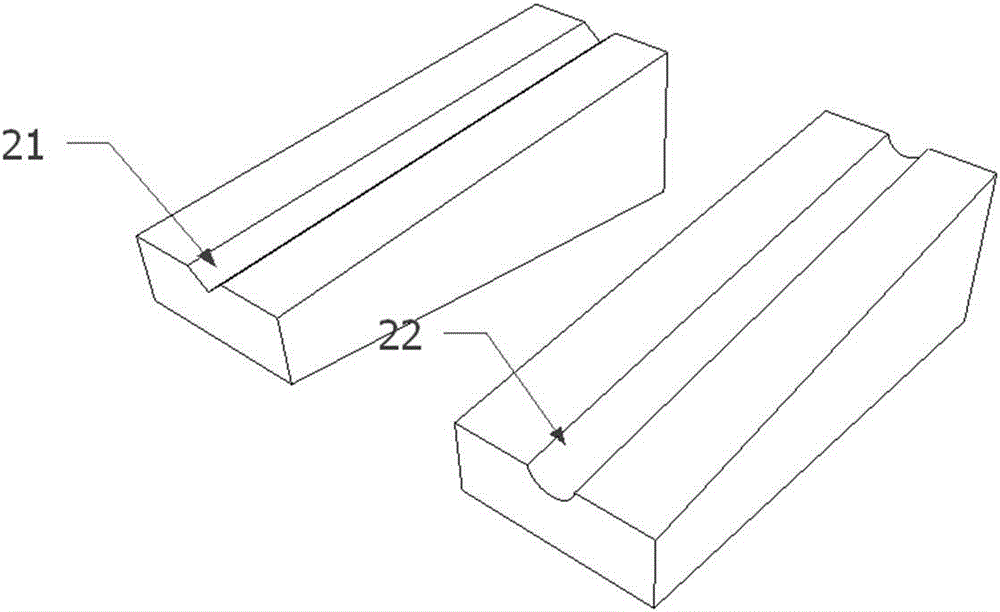

[0022] see image 3 , a pair of clamping blocks are composed of clamping blocks 2 corresponding to the two clamping jaws. The two clamping blocks are respectively provided with groove-shaped jaws 21 for clamping round concentric twisted overhead wires. The jaws 21 are V-shaped jaws; the clamping block 2 is a right-angled trapezoidal block, and the jaws 21 are located on one side of the clamping block 2 at a right angle, and are in a through shape. Two clamping blocks 2 cooperate to form an isosceles trapezoidal block. The jaw ends of a pair of clamping blocks are clamping ends, and the corresponding other ends are positioning ends.

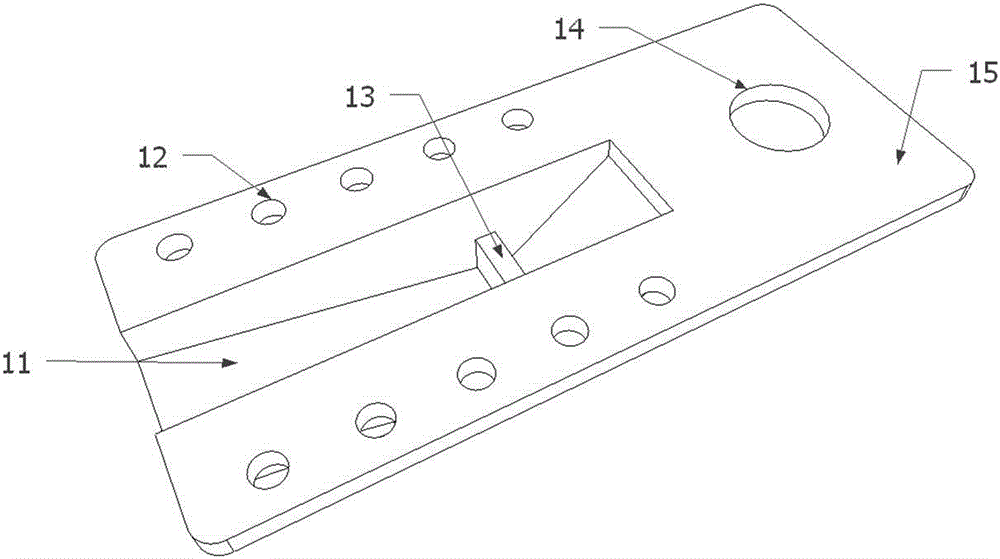

[0023] see figure 2 , a pair of clamp shells are comp...

Embodiment 2

[0028] When testing aluminum stranded aerial conductors, steel-cored aluminum stranded overhead conductors, or other combined aluminum and steel conductors, it is necessary to wrap aluminum foil or aluminum strips at both ends of the overhead conductors first, and select a clamp with an arc-shaped jaw 22 of corresponding specifications. block, see image 3 . Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com