A feeder for pulverized coal boiler

A pulverized coal boiler and feeder technology, which is applied in the field of boiler combustion, can solve problems such as vulcanization, uneven feeding, and instability in combustion, and achieve the effects of solving deflagration, uniform feeding, and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

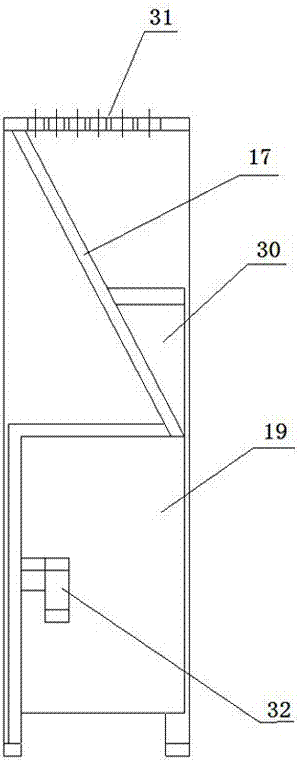

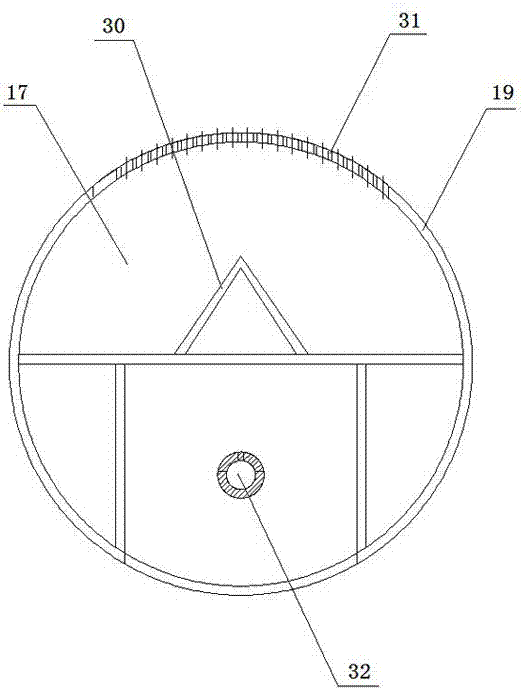

[0054]Start the motor 1, reducer 2 drives the screw shaft 5 to rotate, and the screw blade 6 connected to the screw shaft 5 through the support frame 7 pushes the coal powder falling from the feed hopper 16 to the disc 19, and under the action of the material rack 13, The pulverized coal enters the hopper 11, and the hopper 11 lifts the pulverized coal from the bottom 5 of the turntable 12 under the rotation of the turntable 12, and starts to unload the material above the disc 19. After the pulverized coal is poured out from the hopper 11, it passes through the disc The discharge hole 31 on the disc 19 falls into the disc 19, slides down through the diverter plate 30 along the inner discharge slant plate 17 of the disc 19, and enters the outlet through the discharge hole 29 on the outer blocking plate 18 of the disc. The material box body 10 enters the boiler through the discharge port 9 below the discharge box body 10 .

[0055] The first bearing seat 4 is used to support and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com