Common Rail System Fault Diagnosis System

A technology of fault diagnosis system and common rail system, which is applied in the direction of charging system, testing of machine/structural components, instruments, etc., can solve the problem that maintenance personnel cannot know where the diagnosis program is located, the relationship between each diagnosis step is not displayed, and Do not know the purpose and meaning of the current work, to achieve the effect of user-friendly, easy to understand and operate, and improve maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

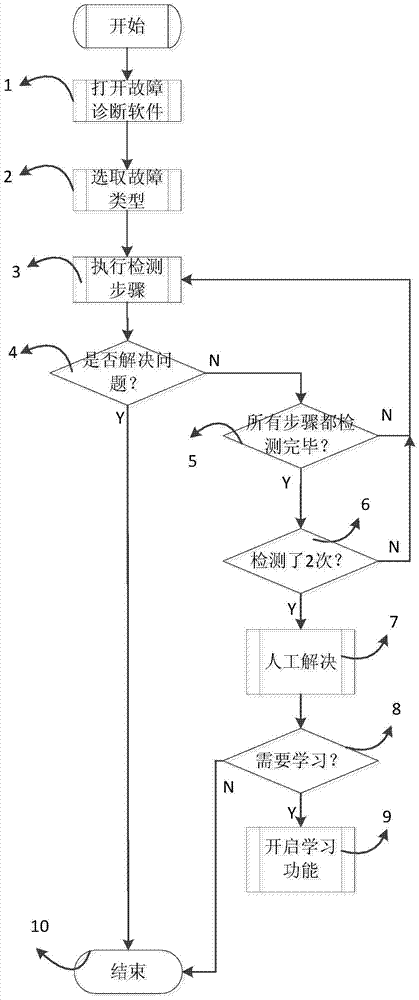

[0032] The present invention will be further described below in conjunction with specific drawings and embodiments.

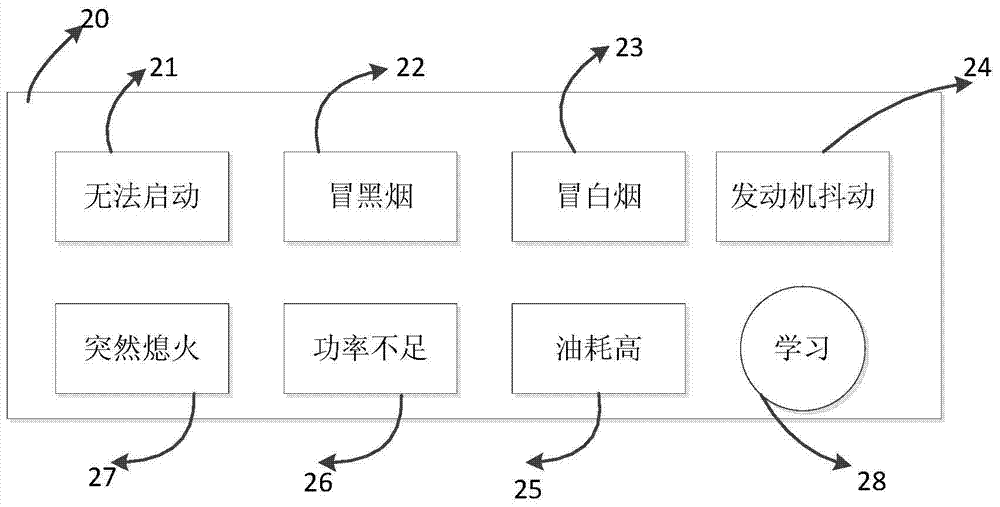

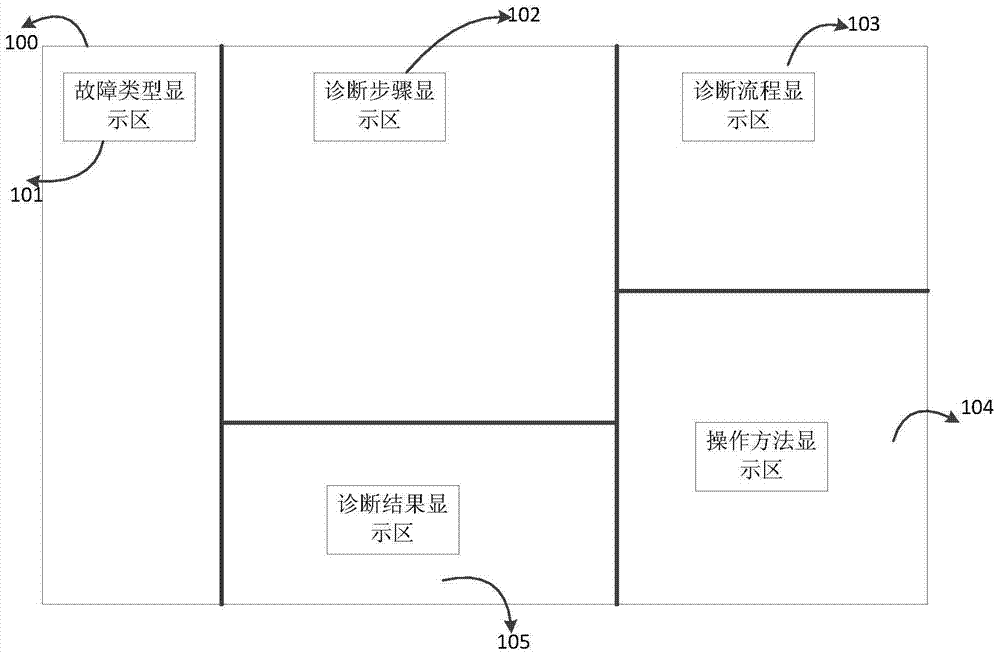

[0033] The present invention includes: a fault type selection interface 20, a fault type operation interface 100, a fault code query interface 121, and a learning function interface 151. The fault type selection interface 20 is used to display various common fault types of the engine, and select a fault type Then enter the corresponding fault type operation interface 100; the fault type operation interface 100 is used to display various diagnostic steps and standard data or standard graphics during diagnosis. For different fault types, there are corresponding special inspection processes and comparison standards; The fault code query interface 121 is used to display the meaning and treatment measures of the current fault code; the learning function interface 151 is used to add diagnostic steps not included in the original system to the system.

[0034] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com