Electric geological core drilling rig

A motor and geological technology, applied in the field of geological survey, can solve the problems of endangering the health of operators, generating noise and exhaust gas, affecting sampling work, etc., and achieving the effects of low noise, not easy to deflect, and good drilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

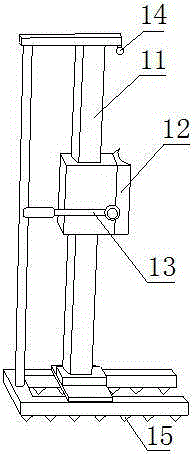

[0021] see Figure 1-5 , an electric geological core drilling machine, including a bracket 1, a power mechanism 2 and a drilling mechanism 3; the bracket 1 includes a support frame 11, a motor bracket 12 and a lifting handle 13, and the motor bracket 12 is slidably sleeved on the support frame 11, the lifting handle 13 is arranged on the motor bracket 12, and is used to fix between the motor bracket 12 and the supporting frame 11, unscrew the lifting handle 13, and the motor bracket 12 can slide up and down along the supporting frame 11, Thereby adjust the position of motor bracket 12, after adjusting, tighten the lifting handle 13, motor bracket 12 is just fixed between support frame 11, and described support frame 11 is provided with illuminating lamp 14, and illuminating lamp 14 can be illuminated When it is insufficient, provide lighting for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com