Method for immobilizing bio-enzyme in ceramic filling material

A technology of ceramic fillers and biological enzymes, applied in the direction of fixing on or in inorganic carriers, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as easy failure, non-reusable use, and unsuitable for industrial production. achieve high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

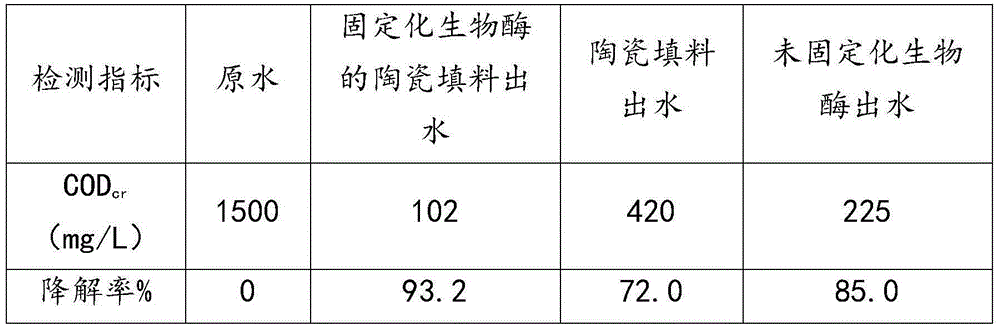

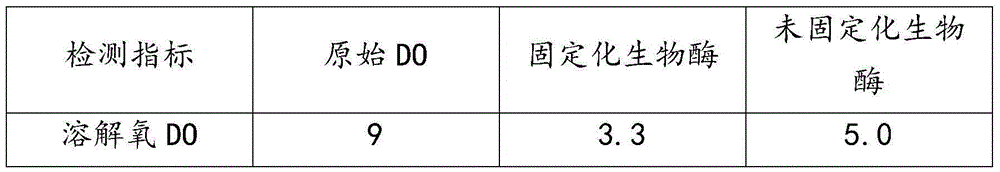

Embodiment 1

[0039] Preparation of alkaline protein modified enzyme solution

[0040] Take 1 liter of distilled water, adjust the pH to 8.3 with 0.5M NaOH, add 2 ml of 30% hydrogen peroxide, and heat the water to 35°C. Weigh 200g of biological enzymes and disperse them in the above aqueous solution, vibrate with a frequency of 50K Hz ultrasonic wave for 20 minutes, then centrifuge at 5000r / min for 15 minutes, take out 600ml of supernatant, and add 2ml of 0.2mol / L borate buffer solution with a pH of 9.0 Dissolve the precipitate and filter out the insoluble matter to obtain 500ml of alkaline protein modified enzyme solution.

[0041] Modifier preparation

[0042] By weight percentage: 5% glucosamine, 10% corn steep liquor, 5% benzoyl peroxide, 1% ferric sulfate, 20% peptone, 59% ethyl acetate are mixed for later use.

[0043] Ceramic filler immobilized biological enzyme

[0044] The diameter of the particles that have been vibrated and screened to remove dust and dust is 10mm, and the spe...

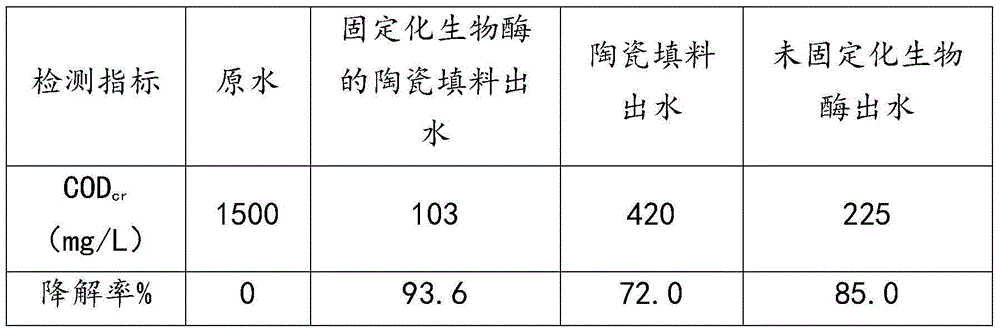

Embodiment 2

[0057] Preparation of alkaline protein modified enzyme solution

[0058] Take 1 liter of distilled water, adjust the pH to 8.5 with 0.5M NaOH, add 2 ml of 30% hydrogen peroxide, and heat the water to 30°C. Weigh 200g of biological enzyme and disperse in the above aqueous solution, vibrate with frequency 40K Hz ultrasound for 20 minutes, then centrifuge at 5000r / min for 15 minutes, take out 600ml of supernatant, add 2ml of 0.2mol / L borate buffer solution with pH 9.0 Dissolve the precipitate and filter out the insoluble matter to obtain 500ml of alkaline protein modified enzyme solution.

[0059] Modifier preparation

[0060] By weight percentage: 3% glucosamine, 12% corn steep liquor, 4% benzoyl peroxide, 2% ferric sulfate, 18% peptone, 61% ethyl acetate are mixed for later use.

[0061] Ceramic filler immobilized biological enzyme

[0062] The diameter of the particles that have been vibrated and screened to remove dust and dust is 10mm, and the specific surface area is 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com