Rapid retraction method for belt conveyer and tape handler for retraction

A belt conveyor and reeling machine technology, applied in conveyors, transportation and packaging, winding strips, etc., can solve the problems of long retraction time, low work efficiency, and the impact of retraction speed and retraction mode, so as to speed up recycling. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

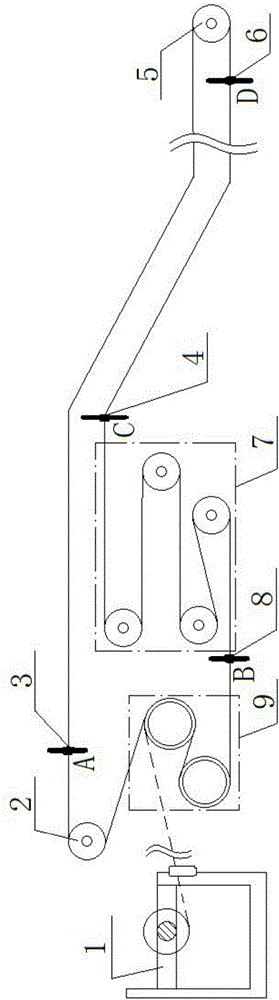

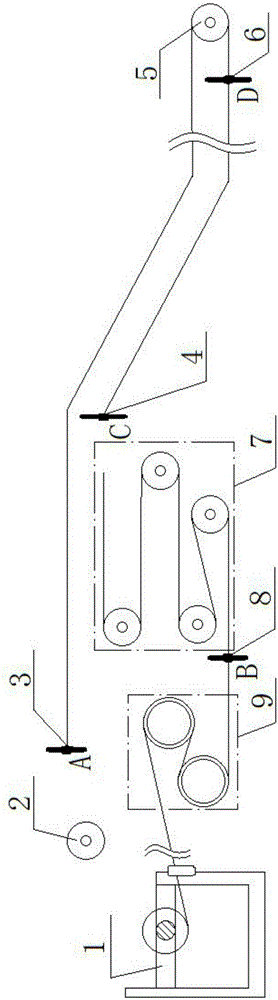

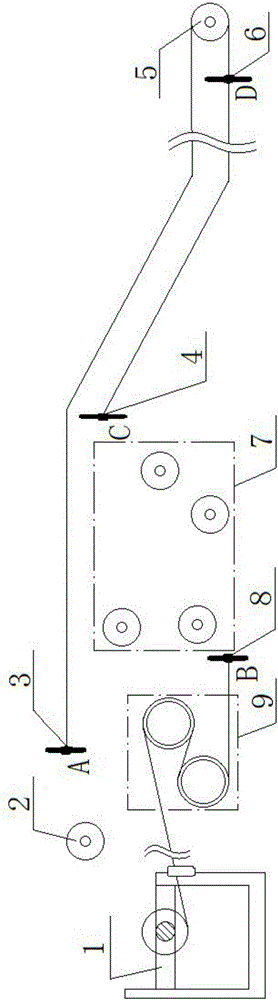

[0025] The method for fast retraction of the belt conveyor includes selecting segmental disconnection points or docking points, disconnecting the belt, rewinding the belt, and reclaiming the belt parts. It is characterized in that the following specific steps are adopted:

[0026] The first step is to select the segment break point and docking point, such as figure 1 As shown, select A disconnection point 3 on the belt near the unloading drum 2 at the top of the machine head; select B docking point 8 near the front end of the lower part of the storage bin 7; on the belt near the upper rear end of the storage bin 7 Select C disconnect point 4; select D disconnect point 6 on the belt near the bottom of the tail drum 5;

[0027] In the second step, the belt is disconnected at the disconnection point, that is, the belt is disconnected at the A disconnection point 3, the C disconnection point 4 and the D disconnection point 6;

[0028] The third step is to retract the belt of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com