Novel plastic injection mould of oblique core-pulling mechanism

An oblique core-pulling and injection mold technology, applied in the field of injection molds, can solve the problems of high requirements on gear-rack precision, small pull-out force and core-pulling distance, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

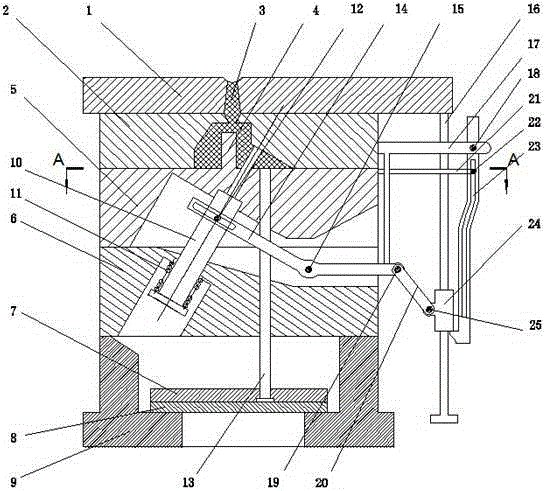

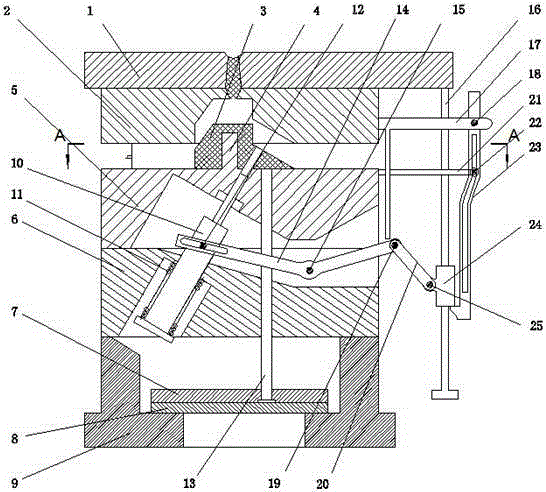

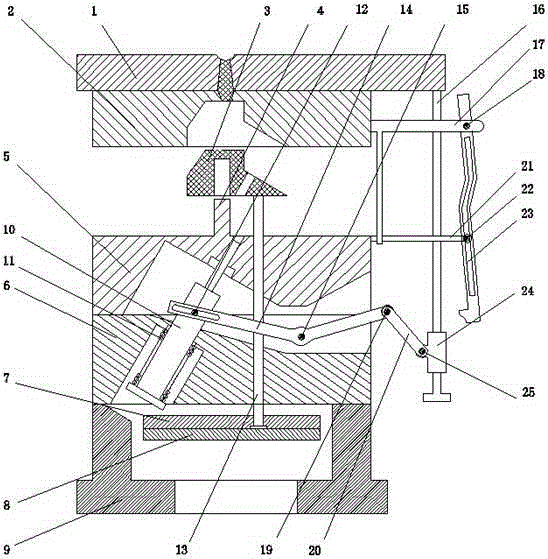

[0022] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0023] The invention provides an injection mold of a new oblique core-pulling mechanism, which adopts a swing rod-bend pin structure for oblique core-pulling. This structure is not only simple in structure and easy to manufacture, but also has a large pulling force and adjustable core-pulling distance. .

[0024] As an embodiment of the present invention, the present invention provides a new type of injection mold with oblique core-pulling mechanism, which includes a fixed mold seat plate 1, a cavity plate 2, a punch 4, a movable platen 5, a support plate 6, and a push plate fixed Plate 7, push plate 8, movable mold seat plate 9, oblique pin 10, push rod 13, swing bar 14, guide rail rod 16, connecting rod 20, bent pin swing hook 23 and slider 24, the movable mold seat plate 9 There is a supporting plate 6 on the supporting plate 6, a movable template 5 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com