Welding machine

A welding ring machine and welding ring technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of damage to the eyes of the operator, poor welding quality consistency, burn through the operator, etc., to prevent Danger, ensure the consistency of welding quality, and ensure the effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content and structural features of the present invention in detail, further descriptions will be made below in conjunction with the embodiments and accompanying drawings.

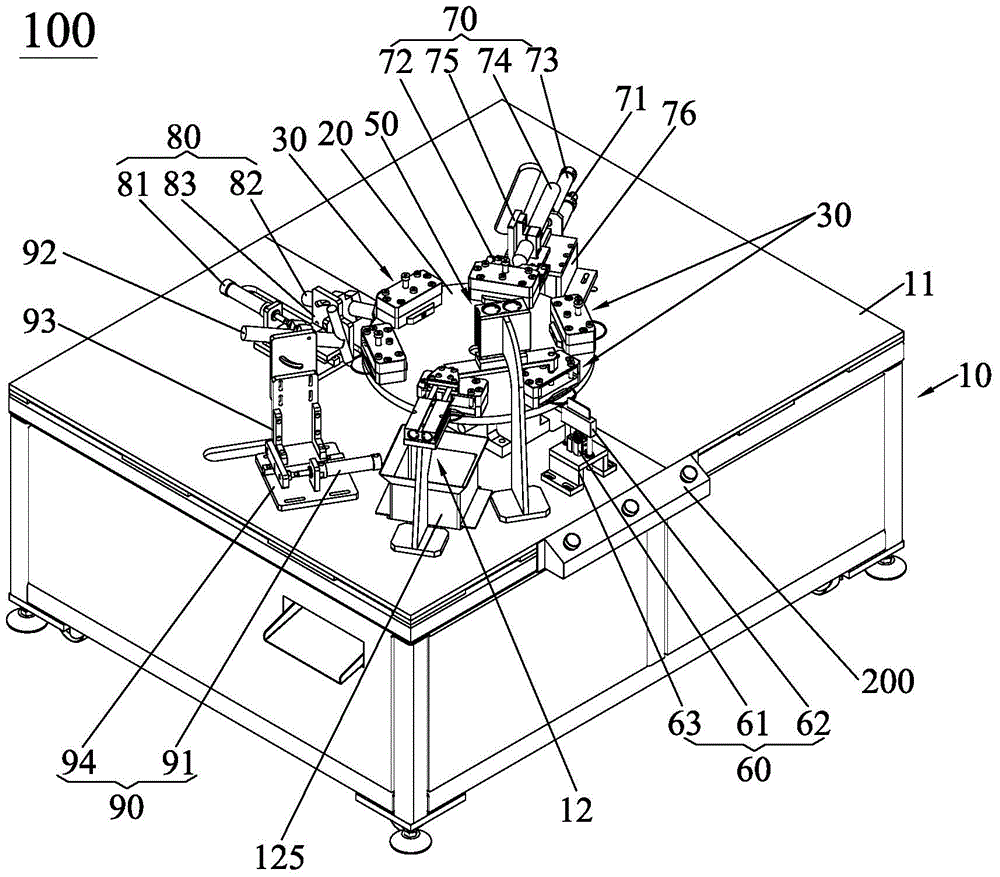

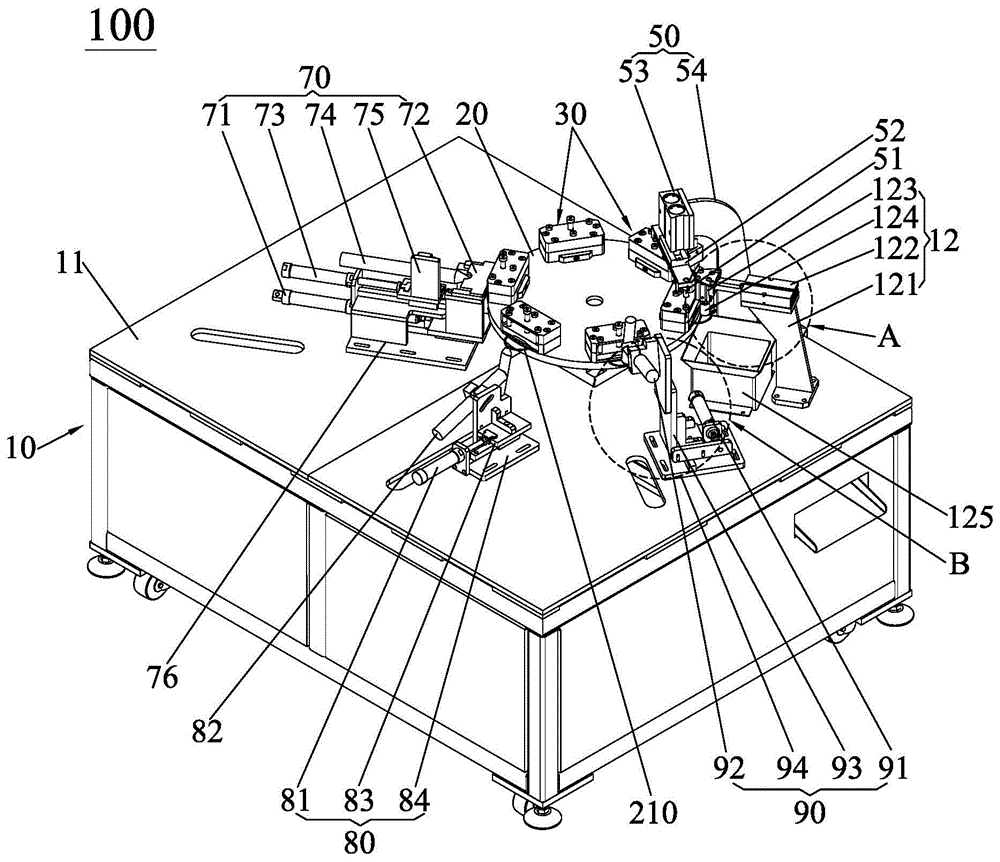

[0025] see figure 1 and figure 2 , the coil welding machine 100 of the present invention is suitable for electrical connection with a controller 200, and the coil welding machine 100 is controlled by the controller 200 to further improve the degree of automation of the coil welding machine 100 of the present invention, and the controller 200 The structure of is well known to those of ordinary skill in the art, so its structure will not be described in detail here.

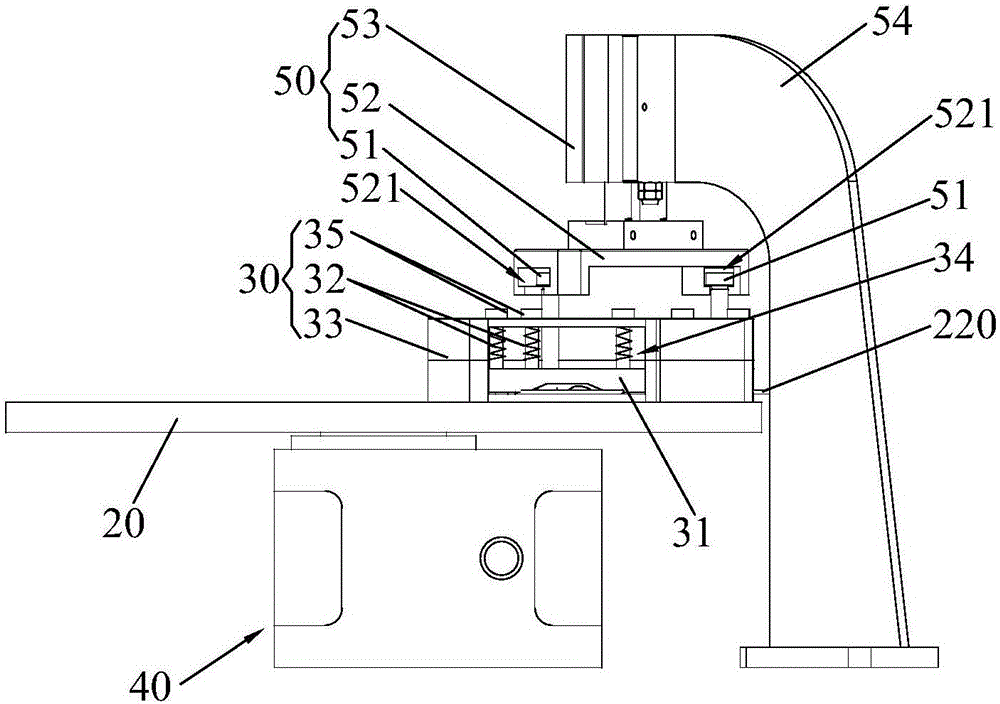

[0026] And the welding ring machine 100 of the present invention is used for welding the two welding ends of the metal ring 210 together, so that the two welding ends of the metal ring 210 that are separated from each other are welded together to form a Figure 5 The solder diagram 220 is shown. Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com