Disc type casting member superpose pouring apparatus convenient to dismount

A technology that facilitates disassembly and casting of castings. It is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of low casting process efficiency, waste of resources, and uneven shrinkage of castings, so as to avoid inaccurate casting sizes and improve production. Casting efficiency, the effect of ensuring the yield of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

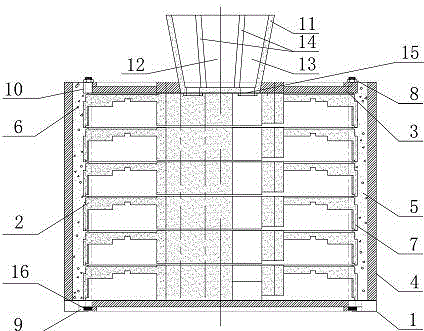

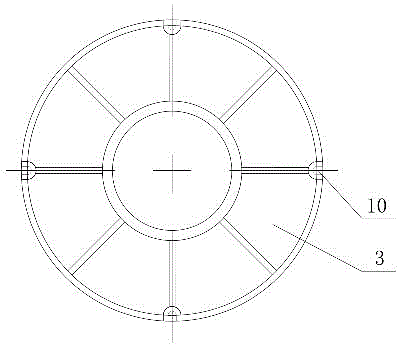

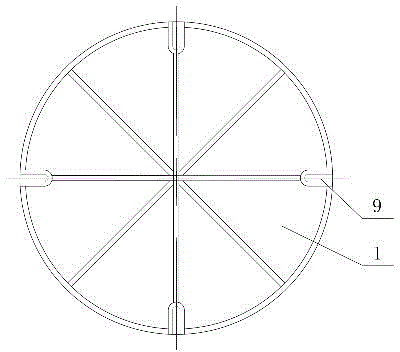

[0021] Such as figure 1 , 2 , 3, and 4 show a conveniently detachable stacking device for disc castings. Sand molds are manufactured with a coated sand core shooter. Each product only needs one pair of molds, and the steel plate is used as the bottom plate (1) to lay Place the product sand mold (2) on the bottom plate (1), and stack the sand mold (2) on the bottom sand mold (2), the bottom of the sand mold (2) is the next layer of sand mold (2) The upper part, and so on, can be stacked and cast more than 10 layers, stacked to an appropriate height, and the upper layer sand mold (2) is provided with an upper pressing plate (3), which can be made of iron plate, and the bottom plate (1 ), the edge ends of the upper platen (3) are respectively provided with grooves (9) and grooves (10).

[0022] Place the stacked sand molds (2) in the cylindrical sandbox (4), fill the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com