A kind of liquid phase synthesis prepares the production method of pure phase cobalt tetroxide

A technology of cobalt tetroxide and liquid phase synthesis, which is applied in chemical methods, chemical instruments and methods, cobalt oxide/cobalt hydroxide and other directions for reacting liquid and gas medium, and can solve the problem of long process flow, reduced product activity and high energy consumption. problems, to achieve the effect of simple process flow and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

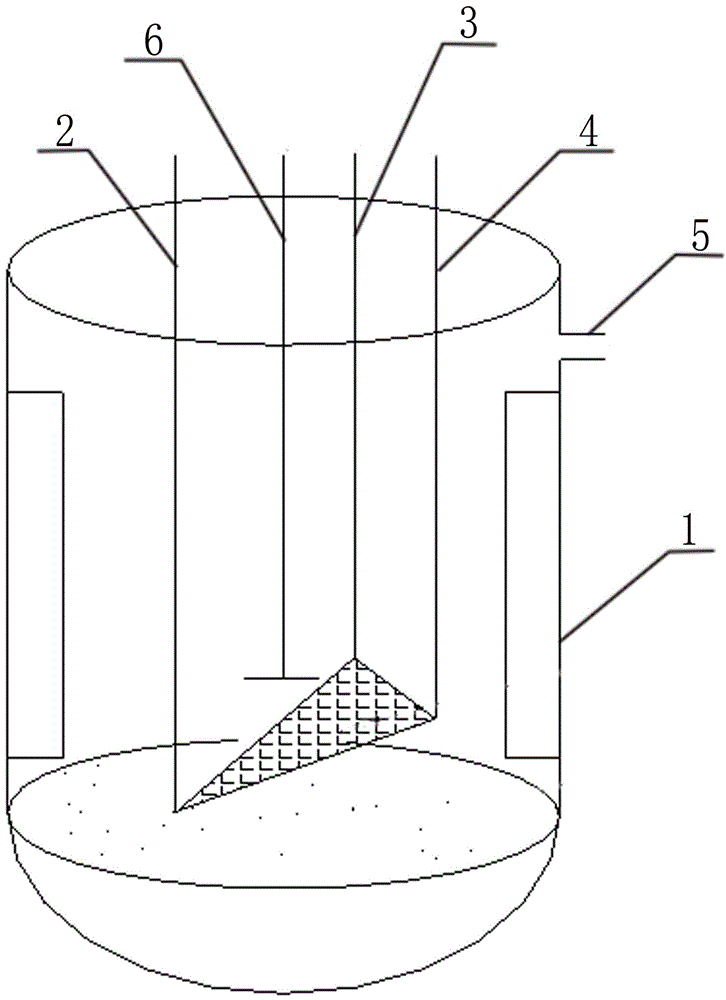

Image

Examples

Embodiment 1

[0016] The method for preparing pure phase cobalt tetroxide by liquid phase synthesis of the present invention comprises the following steps:

[0017] a. Deep degreasing treatment of cobalt chloride solution, adding ethylenediaminetetraacetic acid in proportion to prepare cobalt solution, the cobalt content of cobalt solution is 130g / L, and ethylenediaminetetraacetic acid is added according to 3% of the weight of cobalt metal;

[0018] b. Cobalt solution, lye and air are passed through the cobalt liquid feed pipe, lye feed pipe and air feed pipe respectively to react in the reactor, the concentration of lye is 10mol / L, and the temperature is controlled at 70°C during the reaction , the pH value is between 10, the cobalt chloride flow rate is 280L / h, the lye flow rate is adjusted according to the pH value, and the air flow rate is 18m 3 / h, continuous reaction;

[0019] c. Monitor the oxidation of cobalt chloride in real time. When the oxidation is insufficient, shorten the si...

Embodiment 2

[0022] The method for preparing pure phase cobalt tetroxide by liquid phase synthesis of the present invention comprises the following steps:

[0023] a. Deep degreasing treatment of cobalt chloride solution, adding ethylenediaminetetraacetic acid in proportion to prepare cobalt solution, the cobalt content of cobalt solution is 135g / L, and ethylenediaminetetraacetic acid is added according to 4.0% of the weight of cobalt metal;

[0024] b. Cobalt solution, lye and air are passed through the cobalt liquid feed pipe, lye feed pipe and air feed pipe respectively to react in the reactor, the concentration of lye is 11mol / L, and the temperature is controlled at 80°C during the reaction , the pH value is between 10.4, the cobalt chloride flow rate is 300L / h, the lye flow rate is adjusted according to the pH value, and the air flow rate is 21m 3 / h, continuous reaction;

[0025] c. Monitor the oxidation of cobalt chloride in real time. When the oxidation is insufficient, shorten th...

Embodiment 3

[0028] The method for preparing pure phase cobalt tetroxide by liquid phase synthesis of the present invention comprises the following steps:

[0029] a. Deep degreasing treatment of cobalt chloride solution, adding ethylenediaminetetraacetic acid in proportion to prepare cobalt solution, the cobalt content of cobalt solution is 125g / L, and ethylenediaminetetraacetic acid is added according to 1.0% of the weight of cobalt metal;

[0030] b. Cobalt solution, lye and air are passed through the cobalt liquid feed pipe, lye feed pipe and air feed pipe respectively to react in the reactor, the concentration of lye is 9mol / L, and the temperature is controlled at 60°C during the reaction , the pH value is between 9.7, the cobalt chloride flow rate is 220L / h, the lye flow rate is adjusted according to the pH value, and the air flow rate is 15m 3 / h, continuous reaction;

[0031] c. Monitor the oxidation of cobalt chloride in real time. When the oxidation is insufficient, shorten the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com