Rotatable headrest connection structure

A technology of rotating connection and connecting structure, which is applied in the direction of stools, other seating furniture, household appliances, etc., can solve the problems of low pillow end, low pillow end, discomfort, etc., and achieve production cost saving and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

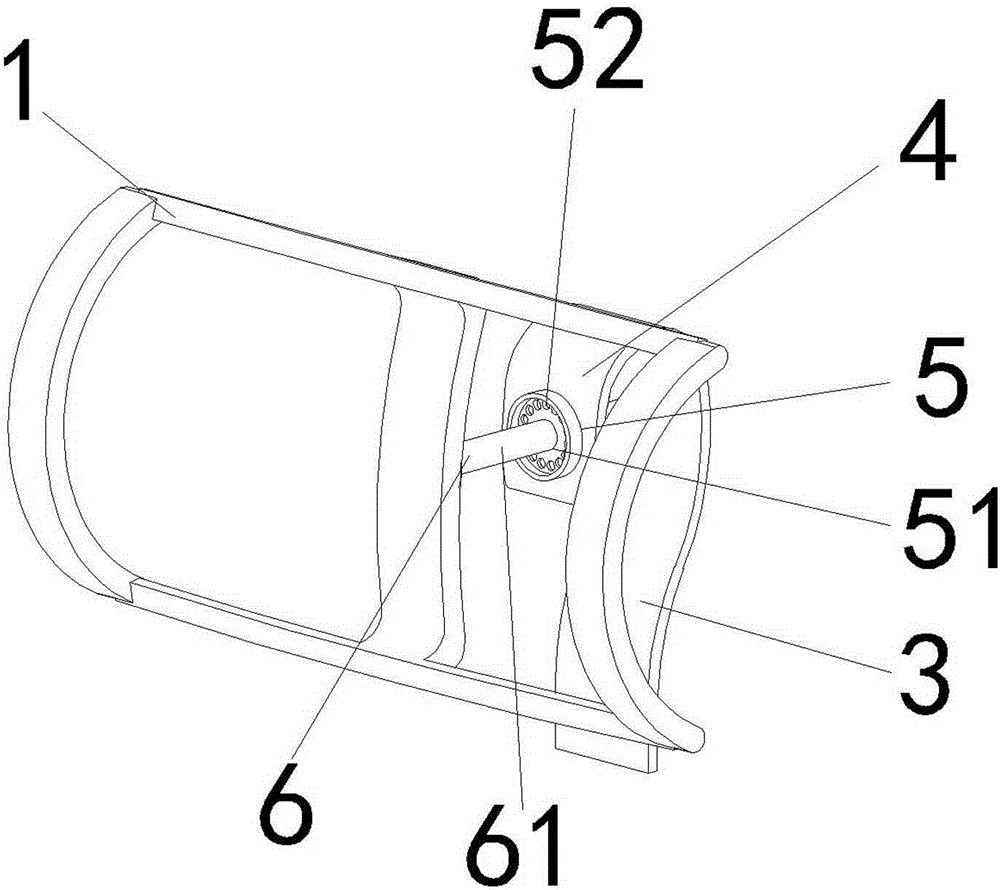

[0028] Embodiment one, such as figure 1 , figure 2 , image 3 and Figure 4 The shown a kind of headrest rotating connection structure comprises headrest supporting frame 1 and backrest supporting frame 2, and connecting structure body 3 is arranged between headrest supporting frame 1 and backrest supporting frame 2, and connecting structure body 3 includes can be connected by rivet. The connecting bracket 4 on the backrest support frame 2 is a cuboid block, and its upper part has a bend on the length side. The bending makes the side view of the connecting bracket 4 an inverted "U" shape, and one end of the bending The back support frame 2 is connected, and the other end is provided with a rotating receiving part 5 . One side of the "U"-shaped bending is provided with a rotating receiving part 5, and the other side is connected to the back support frame 2.

[0029] The rotation receiving part 5 includes a rotation limiting part 51 and a rotation positioning part 52. The r...

Embodiment 2

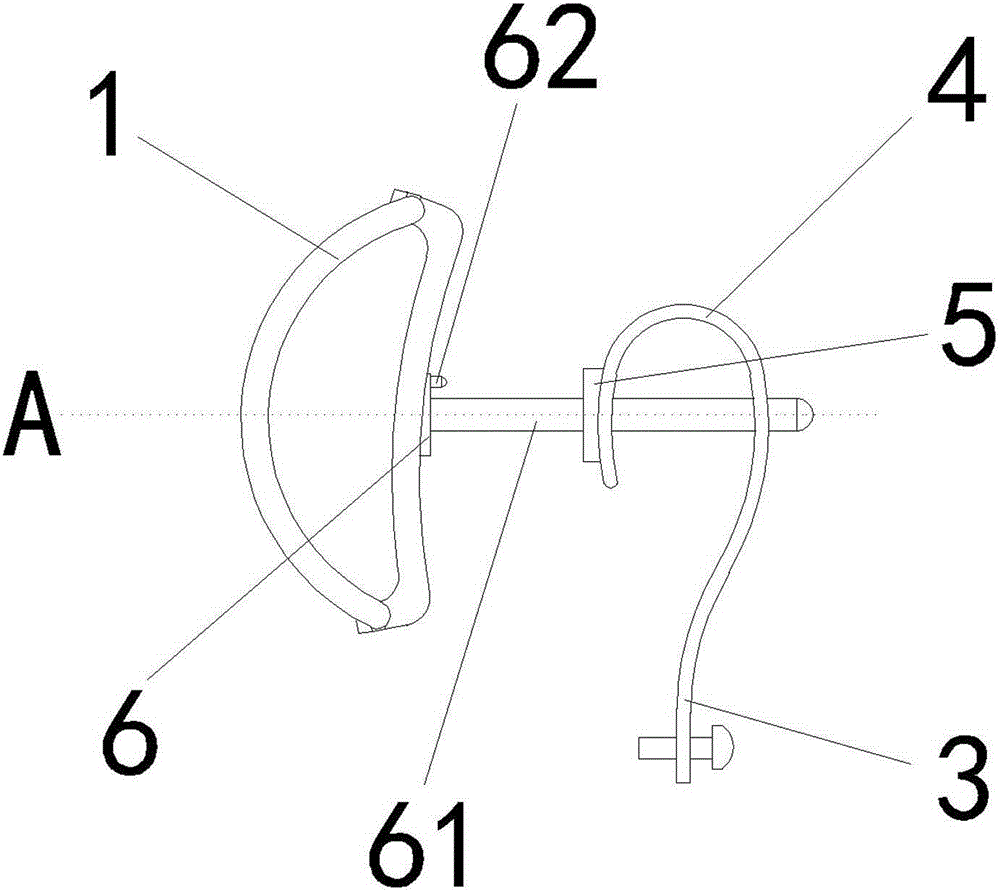

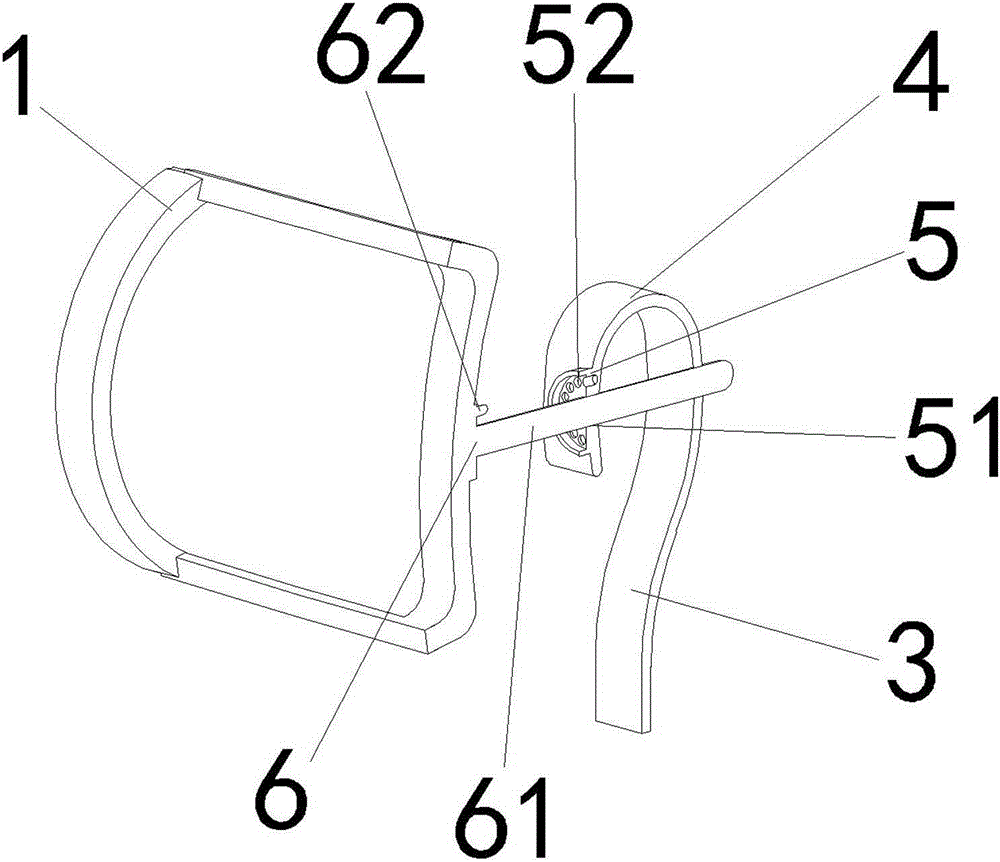

[0032] Embodiment two, such as Figure 5 , Image 6 and Figure 7 A headrest rotation connection structure shown includes a headrest support frame 1 and a backrest support frame 2, and a connection structure body 3 is arranged between the headrest support frame 1 and the backrest support frame 2, and the connection structure body 3 includes a body integrated with the backrest support frame 2. The formed connecting bracket 4 is provided with a rotating receiving part 5 on the connecting bracket 4. The rotating receiving part 5 includes a rotating limiting part 51 and a rotating positioning part 52. The rotating limiting part 51 is a rotating shaft fixing rod, and the rotating positioning part 52 is a A positioning groove arranged around the rotating shaft fixing rod.

[0033] A rotating part 6 is fixedly welded on the pillow support frame 1 , and the rotating part 6 includes a rotating shaft 61 and a positioning part 62 . Rotating shaft 61 comprises the axle sleeve that is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com