Shock absorption motor casing

A technology for motor shells and casings, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., and can solve the problems that it is difficult to improve the internal parts of the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

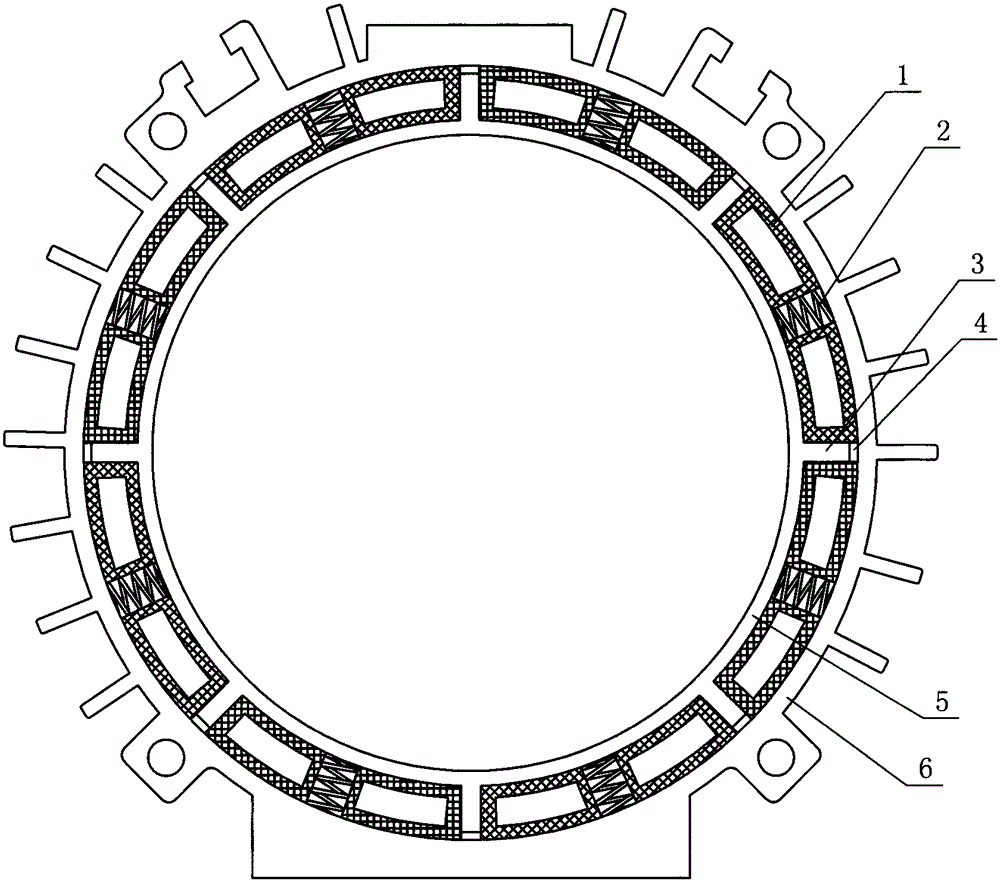

[0011] As shown in the figure, the shock-absorbing motor housing of the present invention includes an inner shell 5 and an outer shell 6 of aluminum alloy profiles, and there are eight fan-ring buffers between the inner shell 5 and the outer shell 6. Pads 1 are separated, the interior of the cushion pads 1 is hollow, and a circumferential gap 4 is provided between adjacent cushion pads 1. The outer wall of the inner shell 5 is provided with eight positioning protrusions 3, and the positioning protrusions 3 Moveably inserted into the circumferential gap 4, a radial spring hole is provided in the middle of the buffer pad 1, and a compression spring 2 is arranged in the spring hole, and the two ends of the compression spring 2 are against the outer wall and the outer wall of the inner shell 5 respectively. The inner wall of the outer shell 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com