Electric vehicle safety charging station with high charging gun utilization rate and low manufacturing cost

A technology for electric vehicles and charging stations, applied in the field of electric vehicles, can solve problems such as hidden safety hazards, easy to wear cable sheaths, and insignificant advantages of charging gun utilization, and achieve the effects of improving coverage, improving utilization, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

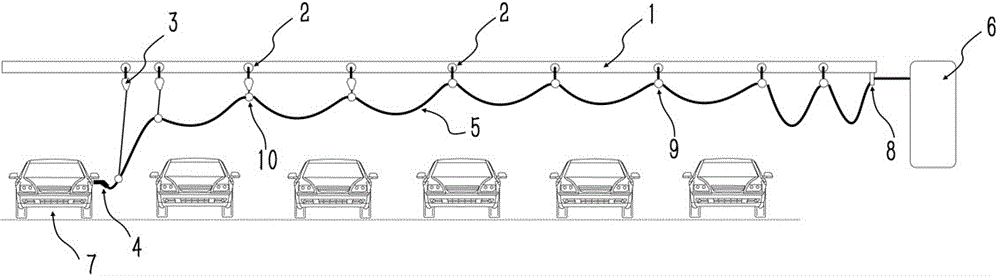

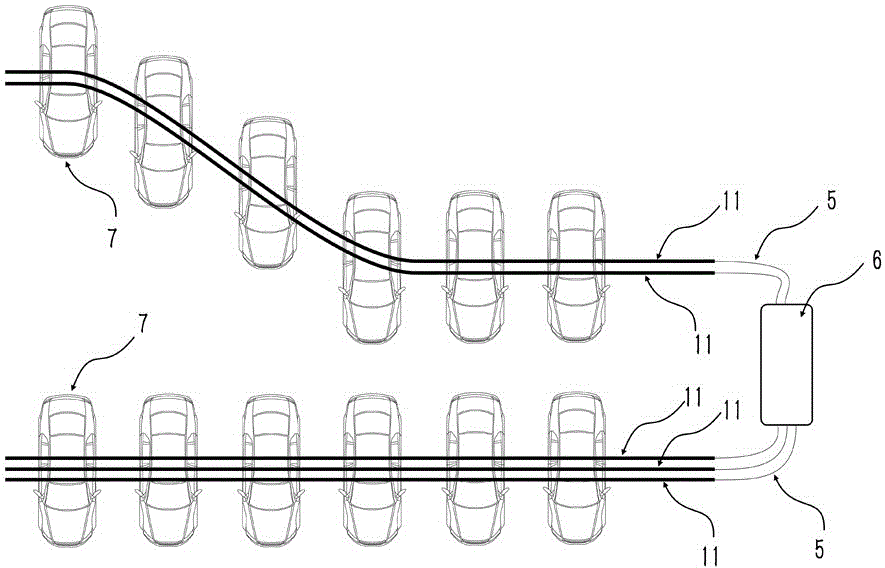

[0025] Electric vehicle safety charging station designed by the present invention, such as Figure 1-Figure 4 shown.

[0026] attached figure 1 From the direction of the front of the car, a mechanical storage device 11 is used to suspend a charging circuit. Car 7, guide rail end cable fixing seat 8, sliding suspension wheel cable fixing clip 9, tension spring balancer cable fixing clip 10, figure 1 The middle charging gun 4 is in the state of charging the electric vehicle 7, the tension spring balancer 3 closest to the charging gun 4 is in an elongated state, and the tension spring balancer 3 adjacent thereto is in a semi-elongated state.

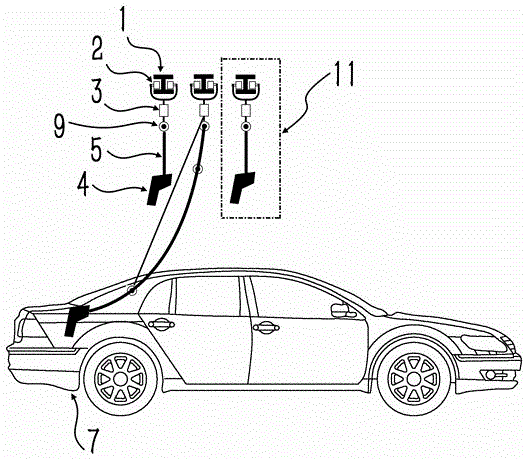

[0027] attached figure 2 Three mechanical storage devices 11 with the same structure are illustrated from the side of the vehicle, one mechanical storage device 11 is inside the dotted line, and the middle mechanical storage device 11 and figure 1 The state is the same, and the charging gun 4 is in the state of charging the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com