Method for temperature rise of sample before dynamic loading process

A dynamic loading and sample technology, which is applied in the preparation of test samples, etc., can solve the problems of large error in results and achieve the effects of improving loading quality, accurate data, and avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

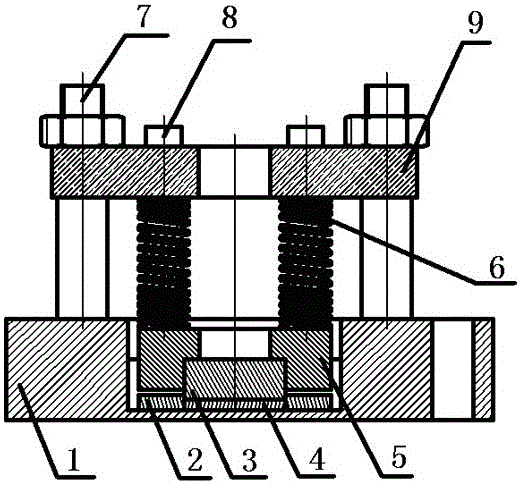

[0024] Such as figure 1 Shown, a kind of method of the present invention is used for sample heating up before dynamic loading process, comprises the following steps:

[0025] (A) Preparation of experimental materials: electrode plate 1 with a polished surface, a cylindrical sample with a diameter of 10 mm, a thickness of 1 mm and polished on both sides 4, and a polished LiF window 3;

[0026] (B) Fix sample 4: apply glue on both sides of sample 4 and bond them to electrode plate 4 and LiF window 3 respectively;

[0027] (C) Fasten sample 4: Before the glue solidifies, limit the LiF window 3, sample 4, and electrode plate 1 in the area where the sample is installed, and apply continuous pressure using the limit loading device: the limit loading device includes limit Position frame 9, the limit frame 9 is fixed on the electrode plate 1 through a plurality of fixing screws 7, a limit rod 8 suspended above the sample 4 is arranged on the limit frame 9, and the bottom end of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com