A lifting platform and its four-column guide rail frame

A technology of lifting platform and guide rail frame, which is applied to the accessories of scaffolding, house structure support, house structure support, etc. It can solve the problems of unreasonable force, achieve a reasonable force system and avoid the effect of guide rail frame occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

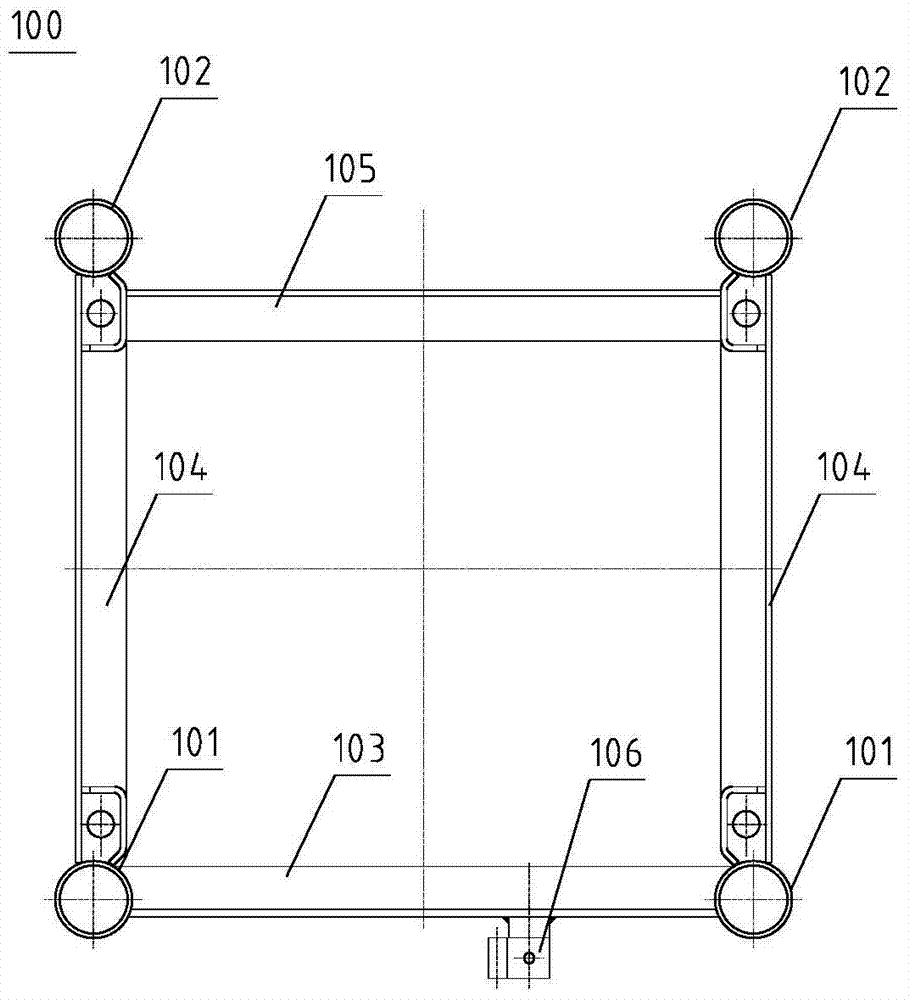

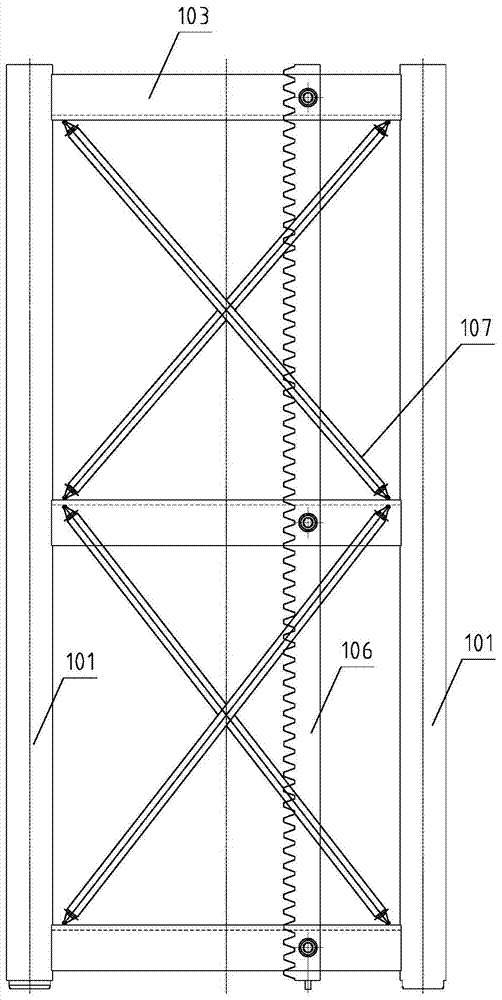

[0029] see Figure 1 to Figure 2 , and please combine image 3 , this embodiment discloses a four-column guide rail frame 100 for a lifting platform, which includes a number of standard sections connected end to end, and each standard energy-saving joint can be freely interchanged. Each standard section includes two rear uprights 101, two front uprights 102 and several crossbeam groups, and the two rear uprights 101 and two front uprights 102 are connected by the several crossbeam groups to form a box structure. The plurality of crossbeam groups are arranged longitudinally at intervals along the front and rear columns 102, 101, and each beam group includes a rear crossbeam 103 connected between two rear columns 101, connected to corresponding front and rear columns 102, Two side beams 104 between 101 and a front beam 105 connected to the two side beams 104 near the front pillar 102 . The front and rear columns 102, 101 are the main vertical load-bearing members, which bear t...

Embodiment 2

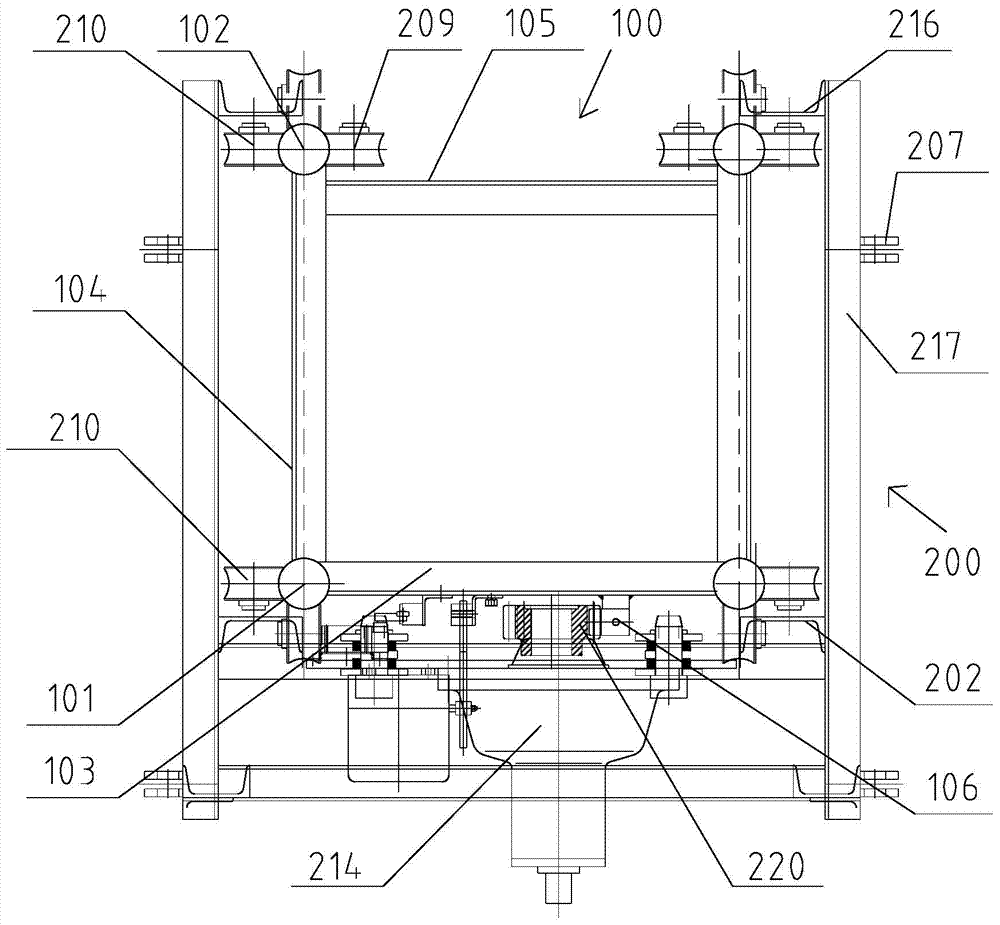

[0036] read on Figure 3 to Figure 5 , and please combine figure 1 and figure 2 , the present invention discloses a lifting platform, which includes a powered upper-mounted stand frame with reverse buckle wheels and a four-column guide rail frame for the lifting platform as described in Embodiment 1. The power top-mounted machine position frame with reverse buckle wheels includes a frame body and platform joints arranged on both sides of the frame body for connecting the platform frame (not shown) and a power supply provided on the frame body. The upper mounting plate 203 on which the motor 214 is installed horizontally, the upper mounting plate 203 is located on the platform surface of the platform frame, the front side of the frame is opened, and the four corners of the top and bottom of the frame are respectively set A pair of vertical pushing wheels, i.e. the upper top wheel one 209 and the upper top wheel two 210 and the lower top wheel one 212 and the lower top wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com