Device for electroplating experiment

An experiment and electroplating solution technology, applied in electrolytic components, electrolytic process, etc., can solve problems such as unsmooth experiments and potential safety hazards, and achieve the effects of avoiding accidents of burning wires, saving costs, and refreshing the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

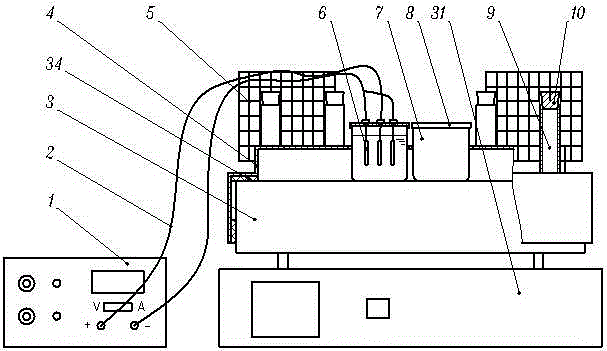

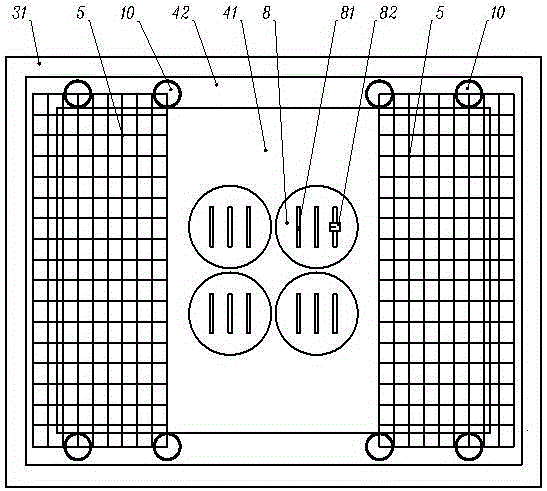

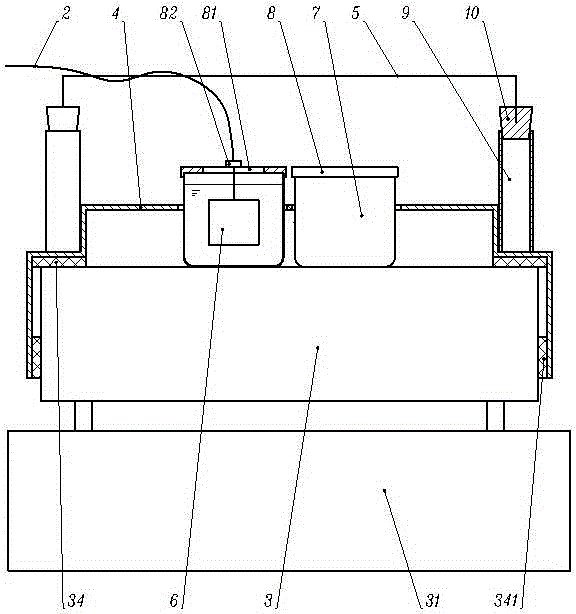

[0012] A device used in electroplating experiments (refer to figure 1 , 2 , 3), the device includes a beaker containing the electroplating solution, an electric heating plate 3 for heating the beaker, an electrode plate 6 inserted into the electroplating solution, and a DC stabilized voltage and current power supply 1 connected to the electrode plate 6 through a wire 2 . In the present invention, the electric heating plate 3 is covered with a convex shield 4, the inner side of the shoulder of the shield 4 rests on the four edges of the electric heating plate 3, and the top surface 41 of the shield 4 There are two to four beaker holes, and the beaker 7 is placed on the electric heating plate 3 through the beaker holes; four or eight hollow columns 9 are arranged symmetrically on the shoulder outer surface 42 of the shield 4 , the upper end of each hollow column 9 is plugged with a thermal insulation plug 10, with four thermal insulation plugs 10 as a supporting group fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com