Cap screwing machine capacity measuring device and measuring method thereof

A measuring device and capping machine technology, applied in capping machine safety/control, threaded bottle caps, etc., can solve the problems of high cost, complex structure, inconvenient maintenance, etc., and achieve low production cost, accurate production capacity measurement, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

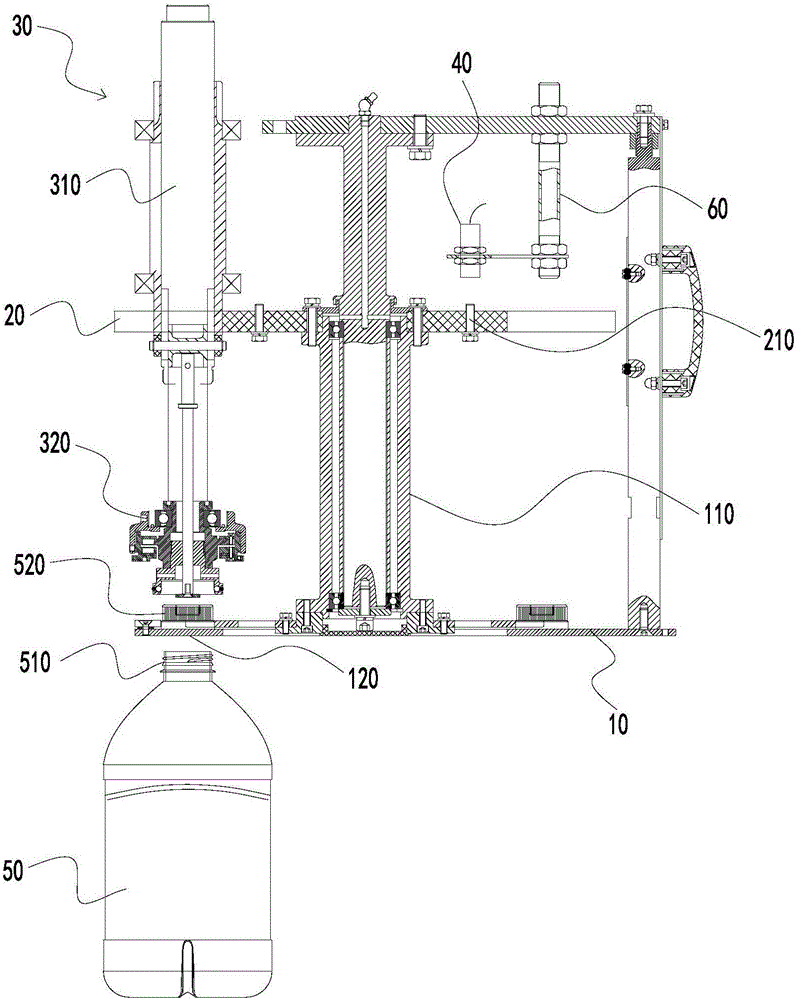

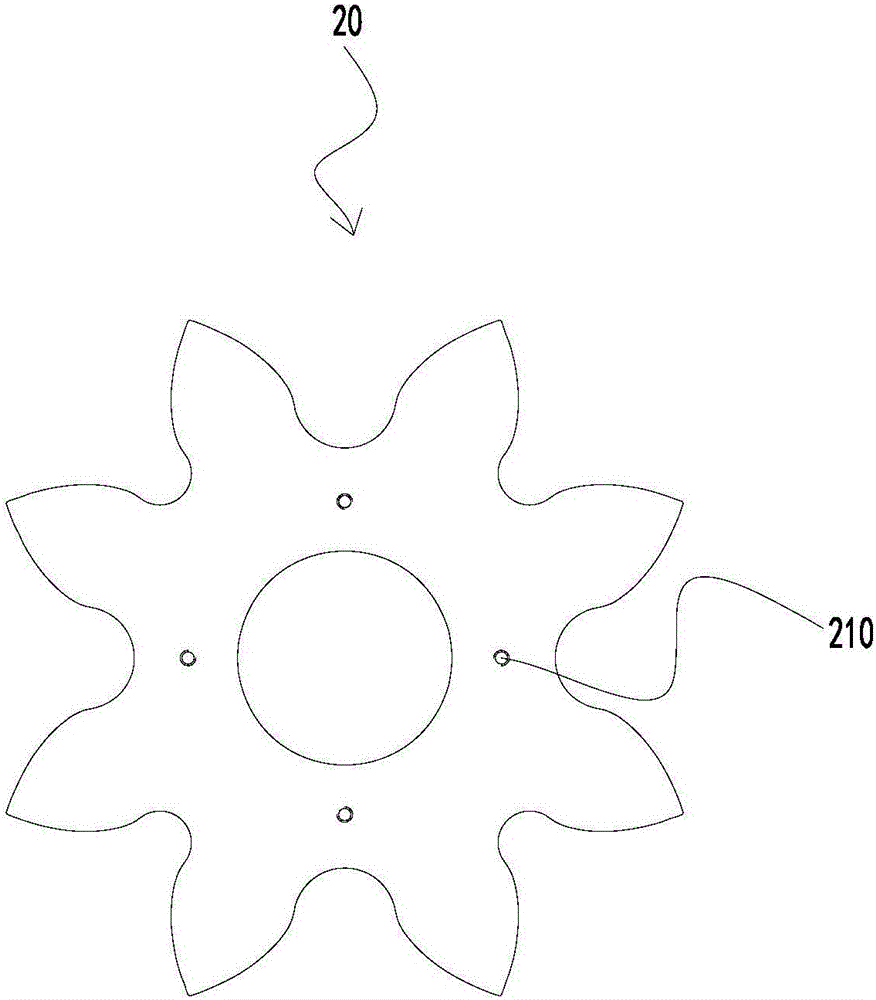

[0028] like figure 1 As shown, a capping machine capacity measuring device includes a support base 10, a support rod 110 arranged on the support base 10, a capping gear 20 sleeved on the support rod 110, and a driving mechanism for driving the capping gear 20 to rotate 30. The sensor 40 located directly above the sub-cover gear 20 , a controller (not marked) electrically connected to the drive mechanism 30 and the sensor 40 , the sub-cover gear 20 is provided with at least one detection part 210 that cooperates with the sensor 40 .

[0029] Start the capping machine, the driving mechanism 30 drives the capping gear 20 to rotate, and when the detection part 210 on the capping gear 20 rotates to the position directly below the sensor 40, the sensor 40 will send a detection signal to the controller. The controller calculates the time interval between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com