A yarn take-up device

A wire take-up device and yarn bobbin technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, and thin material processing, etc., can solve problems affecting production efficiency, failure, and interruption of yarn collection, etc., and achieves simple structure and improved use. Effect of life, good tensioning action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

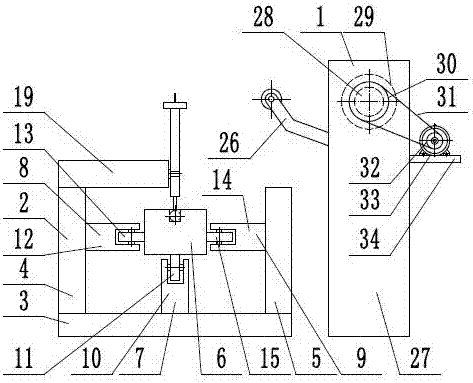

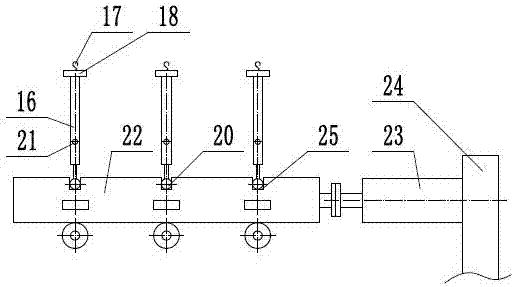

[0013] Such as figure 1 and figure 2 As shown, a yarn take-up device includes a yarn take-up mechanism 1 and a yarn guide mechanism 2, the yarn take-up mechanism 1 is arranged on the right side of the yarn guide mechanism 2, and the yarn guide mechanism 2 realizes the guidance of the yarn effect, and ensure that the yarn swings back and forth, which is conducive to the uniform yarn collection of the yarn bobbin 29 on the yarn receiving mechanism 1. The yarn receiving mechanism 1 realizes the rapid yarn receiving of the yarn, and is simple in structure, economical and practical. The yarn guide mechanism 2 includes a base 3, a left bracket 4, a right bracket 5, a swing yarn guide assembly 6, a lower guide assembly 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com