Purifier

A purifier and housing technology, applied in the field of purification, can solve the problems of no recovery mechanism, expensive replacement costs, difficulty in meeting purification requirements, etc., and achieve the effect of simple and reasonable structure and clean air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

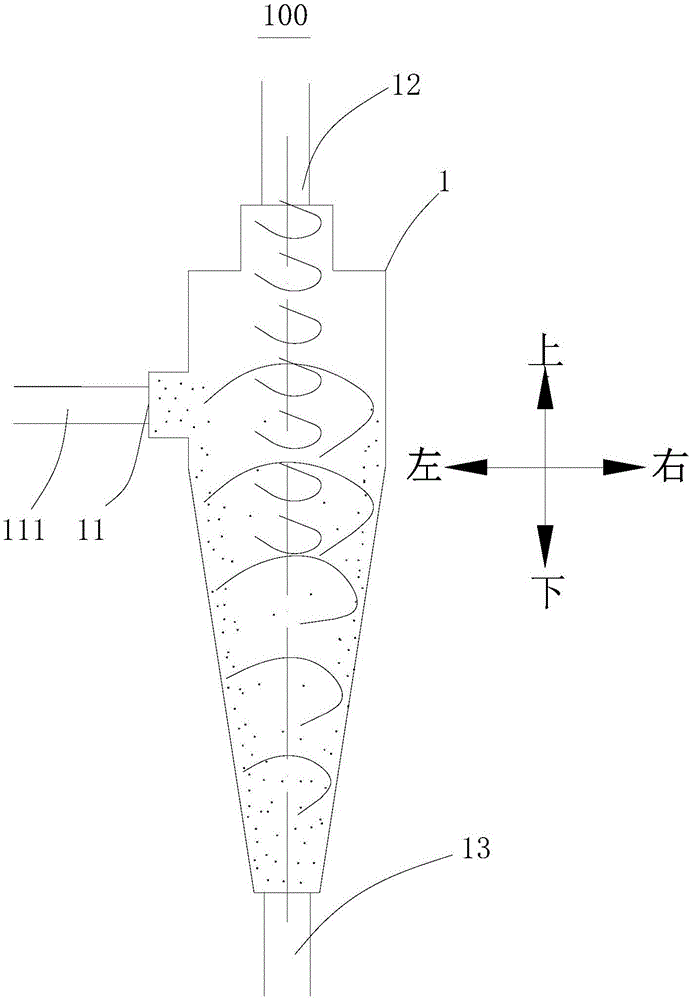

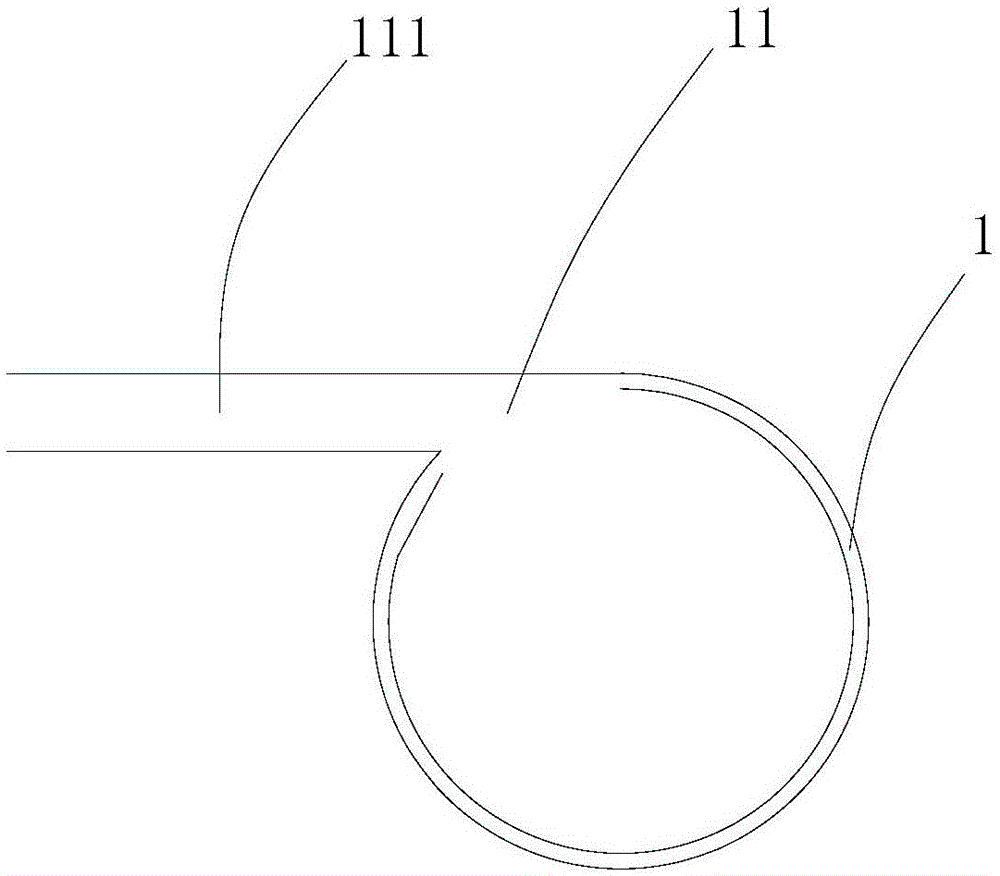

[0056] refer to figure 1 with figure 2 The purifier 100 includes a first purification housing 1, the side wall of the first purification housing 1 has a first air inlet 11 extending along its tangential direction, and the top of the first purification housing 1 has a first air outlet 12 , the bottom of the first purification housing 1 has a first dust outlet 13 .

[0057] In this way, the unpurified air enters into the first purification housing 1 from the first air inlet 11 along the tangential direction of the first purification housing 1 to form a swirling airflow, and under the action of centrifugal force and gravity, the dust goes downward. Collected at the first dust outlet 13 and discharged, the purified air is discharged from the first air outlet 12 on the top of the first purification housing 1 under negative pressure, and the air is purified once.

Embodiment 2

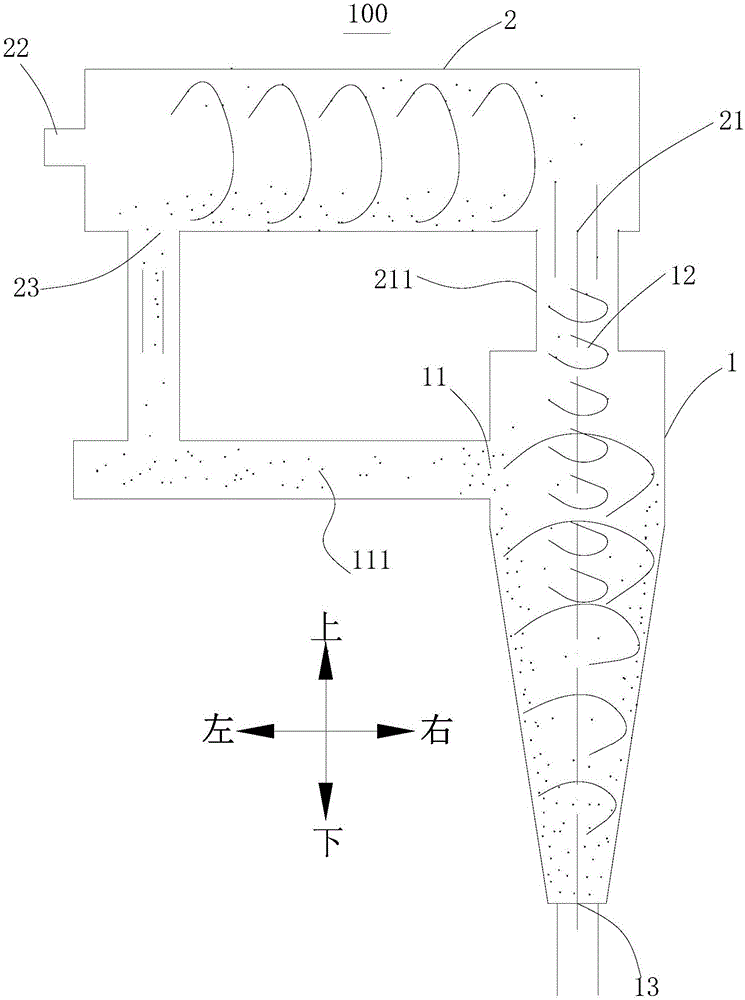

[0059] refer to image 3 with Figure 4 , the structure of the second embodiment is substantially the same as that of the first embodiment, wherein the same components use the same reference numerals, the only difference is that the purifier 100 also includes a second purification housing 2, and the second purification housing 2 There is a second air inlet 21 extending along the tangential direction on the side wall, the second air inlet 21 is connected with the first air outlet 12, and the left end of the second purification housing 2 has a second air outlet 22 and a second air outlet. The dust outlet 23 and the second dust outlet 23 are connected to the first air inlet 11 .

[0060] In this way, the unpurified air enters into the first purification housing 1 from the first air inlet 11 along the tangential direction of the first purification housing 1 to form a swirling airflow, and under the action of centrifugal force and gravity, the dust goes downward. Collected at the...

Embodiment 3

[0062] refer to Figure 5 , the structure of this embodiment is substantially the same as that of Embodiment 2, wherein the same components use the same reference numerals, the only difference is that the second air inlet 21 and the side of the second purification housing 2 in Embodiment 2 The walls are connected tangentially, but the second air inlet 21 in the third embodiment is not connected tangentially to the side wall of the second purification housing 2 , and the second air inlet 21 is provided with an anion emitting head 24 .

[0063] In this way, the unpurified air enters into the first purification housing 1 from the first air inlet 11 along the tangential direction of the first purification housing 1 to form a swirling airflow. Collected at the first dust outlet 13 and discharged, the purified air is discharged from the first air outlet 12 on the top of the first purification housing 1 under negative pressure, the air is purified once, and the air discharged from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com