Terminal crimping device

A terminal crimping and terminal technology, which is applied in the direction of connection, electrical components, circuits, etc., can solve the problem of position deviation and achieve the effect of suppressing the generation of metal powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0063]

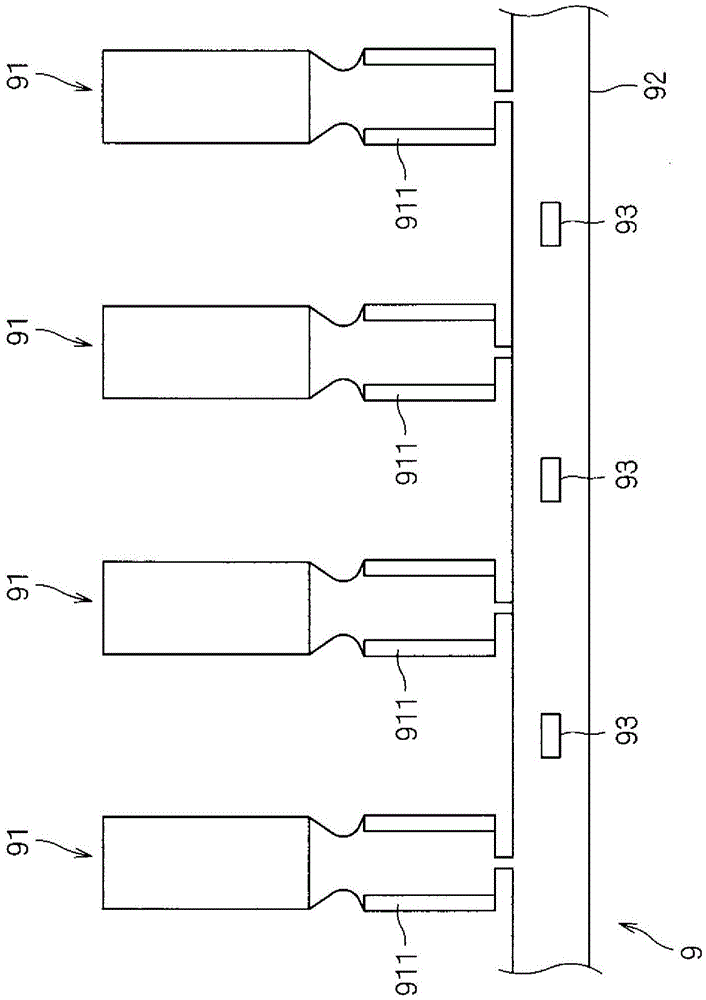

[0064] First, regarding the continuous terminal 9 as the object of the terminal crimping device 1, refer to figure 1 Be explained. figure 1 It is a plan view showing the continuous terminal 9 .

[0065] The continuous terminal 9 is a belt-shaped member in which a plurality of terminals 91 are connected. Specifically, a plurality of terminals 91 are formed in parallel at equal intervals on one side of a belt-shaped interlocking belt 92 . In the interlocking belt 92 , corresponding to the respective terminals 91 , transmission holes 93 are formed at equal intervals. A base portion (barrel portion) 911 of each terminal 91 is formed to be open in a substantially U-shaped cross section so that it can be crimped to an end portion of an electric wire.

[0066]

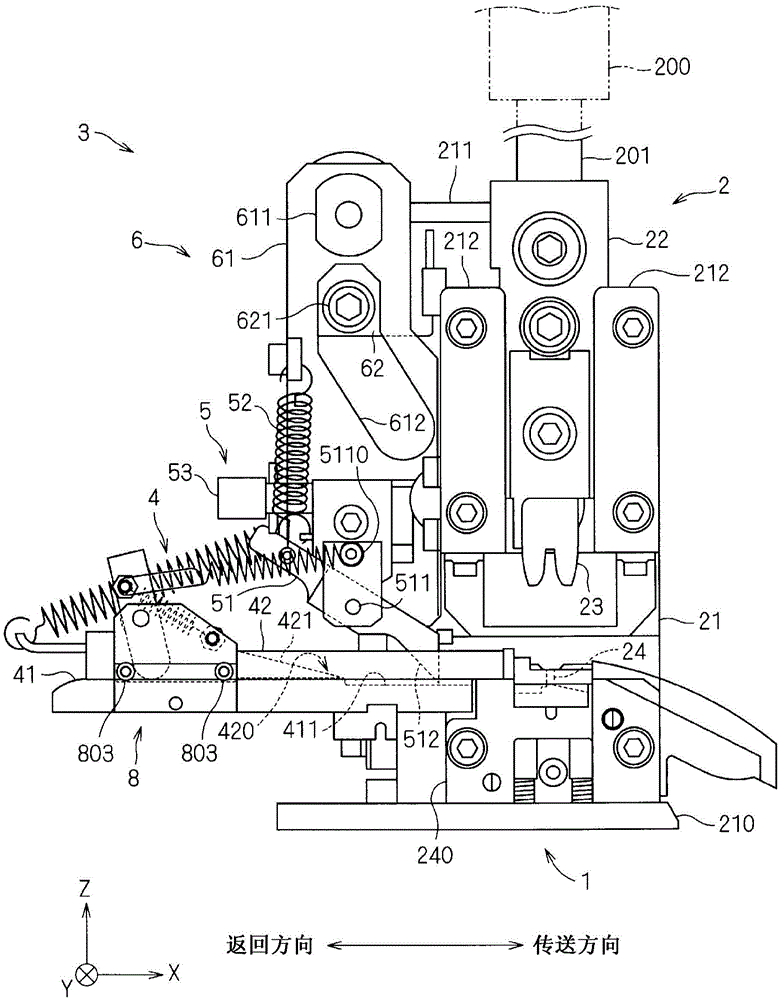

[0067] For the structure of the terminal crimping device 1, refer to figure 2 Be explained. figure 2 It is a schematic front view of the terminal crimping device 1 . It should be noted that, in figure ...

no. 2 approach

[0170] The terminal crimping device 1a of the second embodiment will be described. Figure 16 The schematic front view of the terminal crimping apparatus 1a of 2nd Embodiment is shown. The terminal crimping device 1a has the same structure as the terminal crimping device 1 of the first embodiment except that the structure of the one-side stopper is different. Furthermore, the operation of the terminal crimping device 1a is also the same as that of the terminal crimping device 1 of the first embodiment.

[0171]

[0172] The one-side brake unit (brake unit) 7 included in the terminal crimping apparatus 1 a brakes the movement of the continuous terminal 9 similarly to the one-side brake unit 8 in the above-mentioned embodiment. That is, the one-side stopper 7 is the same as the one-side stopper 8 of the above-mentioned embodiment, and the upstream side (-X side) of the transport claw 51 in the transport direction is connected to the continuous terminal 9 placed on the stage 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com