Flat-touch screen and manufacturing method thereof

A manufacturing method and touch screen technology, which are applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of wasting labor, the upper conductive layer is easily scratched, and the optical glue is difficult to clean. , to achieve the effect of preventing electrical performance and avoiding bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

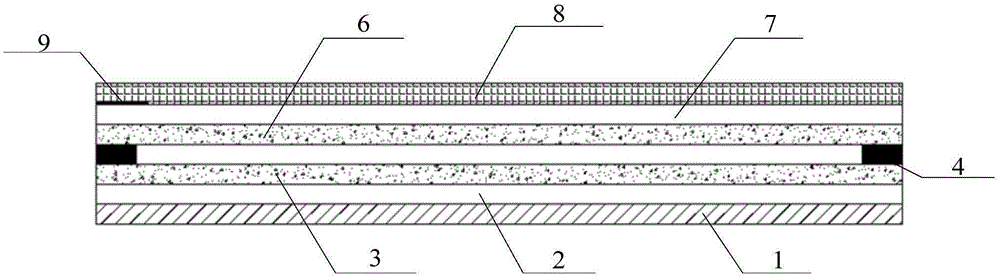

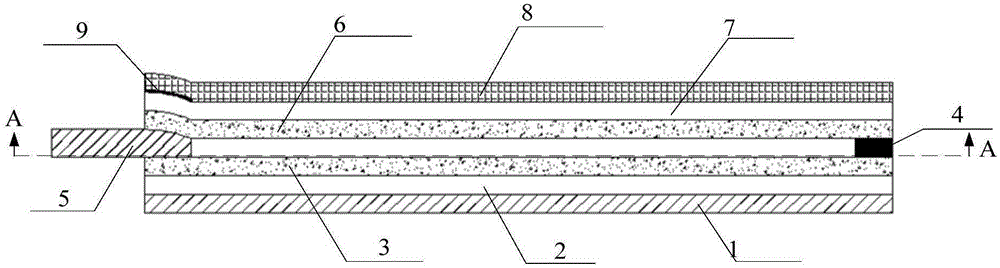

[0026] Such as Figure 1-2 As shown, a flat touch screen provided by the embodiment of the present invention includes a flexible circuit board 5 and a glass substrate 1, a lower optical adhesive layer 2, a lower conductive layer 3, a double-sided adhesive 4, an upper conductive layer 6, The upper optical adhesive layer 7 and the cover plate 8; the flexible circuit board 4 is electrically connected to the lower conductive layer 3 and the upper conductive layer 6 respectively and is arranged between them; an electronic coating is arranged between the upper optical adhesive layer 7 and the cover plate 8 layer 9, and the electronic coating 9 is located directly above the flexible circuit board 5.

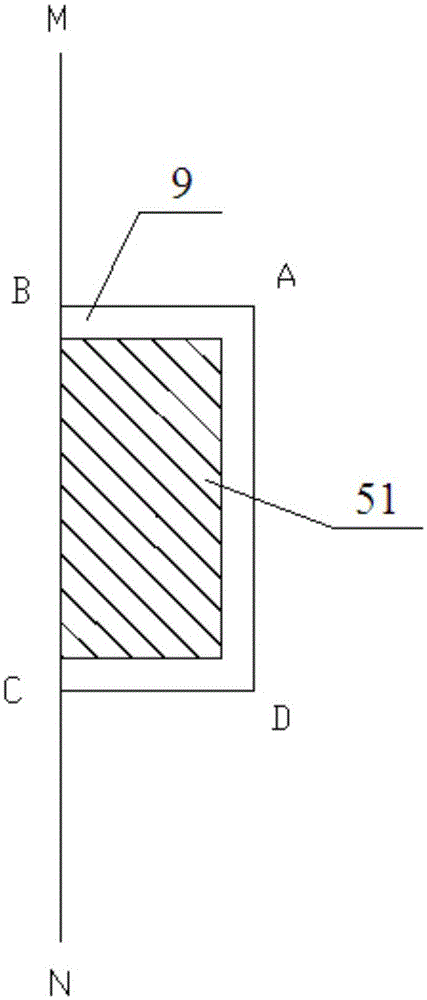

[0027] Specifically, in this embodiment: the flexible circuit board 5 is bonded between the lower conductive layer 3 and the upper conductive layer 6 through the anisotropic conductive adhesive film, and the Bonding area (that is, the binding or sticking area) 51 is arranged on the flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com