Automatic tester for dielectric strength of insulating oil

A dielectric strength and tester technology, which is applied in the direction of testing dielectric strength, etc., can solve the problems of manual printing, automatic reset, and influence on the accuracy of test data, etc., and achieve the effect of simple operation and elimination of unevenness and air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

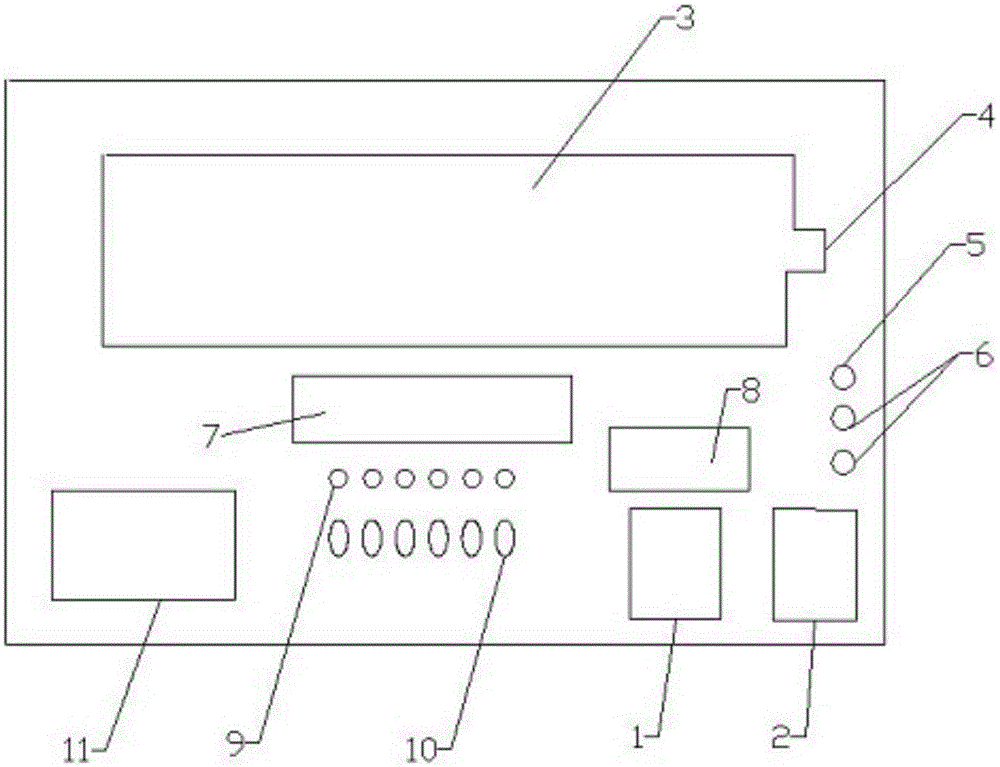

[0051] Example 1, such as figure 1 As shown, the automatic dielectric strength tester for insulating oil includes a control panel, and the control panel has a power switch 1, a power socket 2, a high voltage chamber 3, a safety switch 4, a safety grounding socket 5, 3A insurance 6, and a display screen 7 , setting plate 8, indicator light 9, keyboard 10 and printer 11.

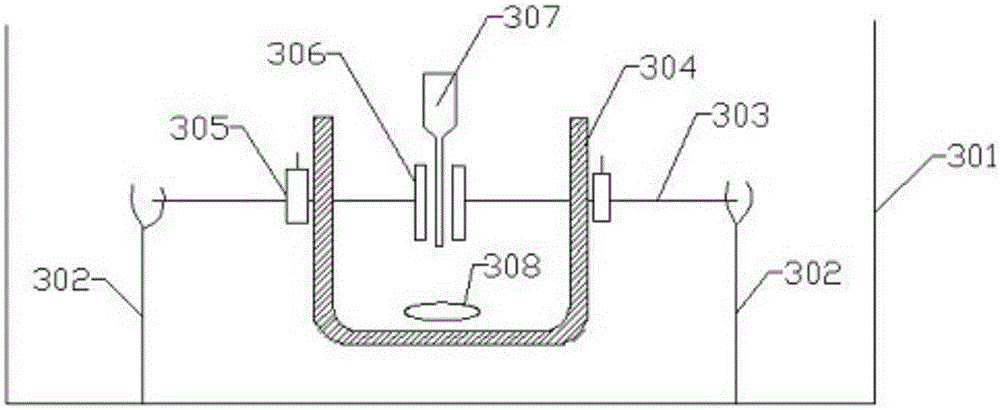

[0052] Such as figure 2 As shown, the hyperbaric chamber 3 includes a hyperbaric chamber body 301 , and two high-pressure columns 302 are arranged inside the hyperbaric chamber body 301 , and an oil cup 304 is arranged between the two high-pressure columns 302 .

[0053] The cup wall of the oil cup 304 is connected with two shafts 303, the shafts 303 run through the cup wall of the oil cup 304, one end of the shaft 303 is arranged inside the oil cup 304, and the other end of the shaft 303 is arranged in the oil cup 304 outside, the oil cup 304 is supported between two high-voltage columns 302 through the sh...

Embodiment 2

[0065] Embodiment 2, an automatic tester for the dielectric strength of insulating oil, differs from Embodiment 1 in that at least two high-voltage columns 302 are provided in the hyperbaric cabin body 301, and each two is a group, and each group of high-voltage columns 302 can be provided with one The hyperbaric chamber 3 can carry out multiple experiments at the same time, which greatly improves the work efficiency.

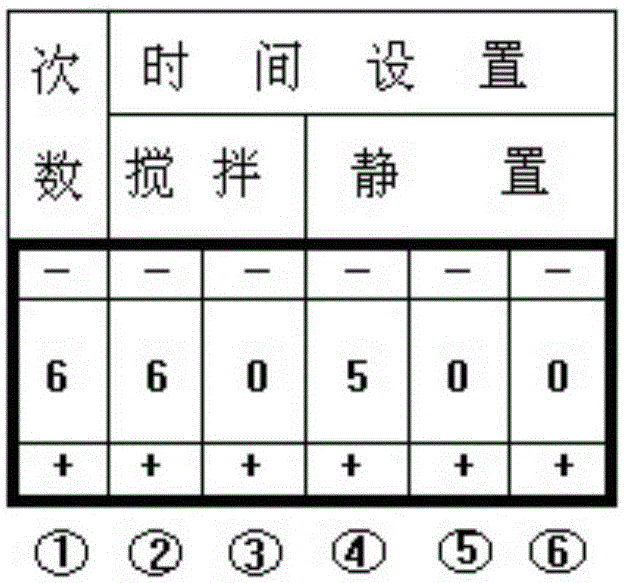

[0066] Such as Figure 3-Figure 9 Shown, tester operating steps of the present invention are as follows:

[0067] 1. Input power

[0068] Connect the safety ground, plug in the 220V AC power supply, and check that the power supply is correct.

[0069] 2. Take oil samples

[0070] 2.1. Adjust the distance between the two electrodes 306 in the oil cup 304 to 2.5mm; adjust the electrode 306 in the oil cup 304 to the middle position, tighten the shaft fixing screw 305, and take the feeler gauge 307 between the two electrodes 306 Close to the two electrodes 306,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com