Coil pushing mechanism capable of automatically aligning and transferring fabric coils

A technology of moving mechanism and coil, which is applied in knitting, textile and paper making, etc. It can solve the problems of high efficiency and quality, limited work efficiency, high labor cost, etc., and achieves simple structure, few components and accurate movement high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

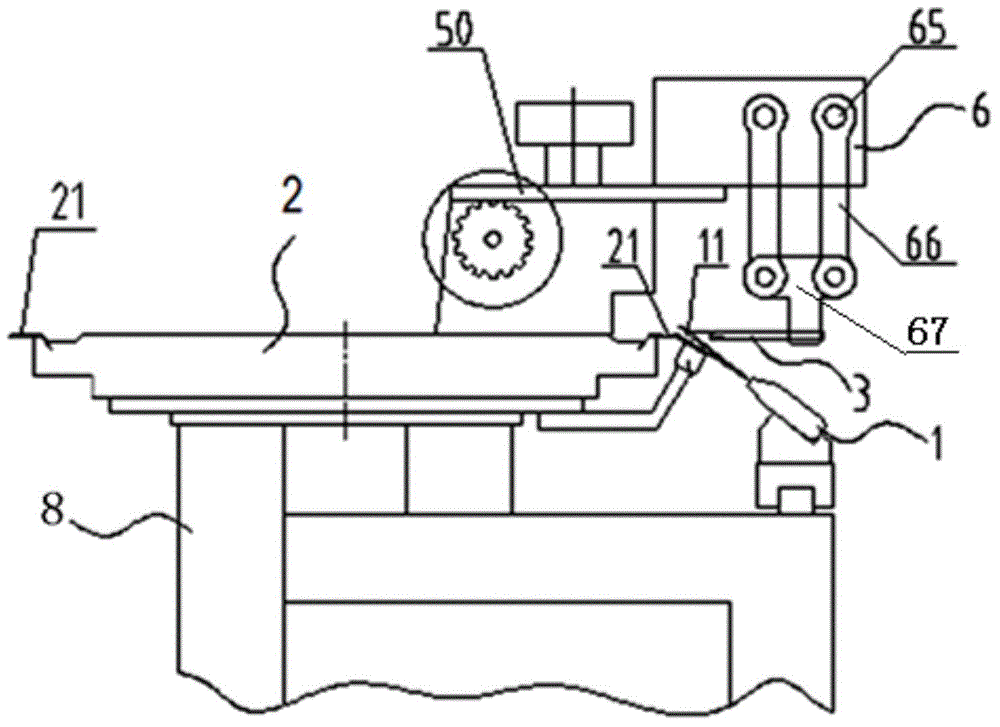

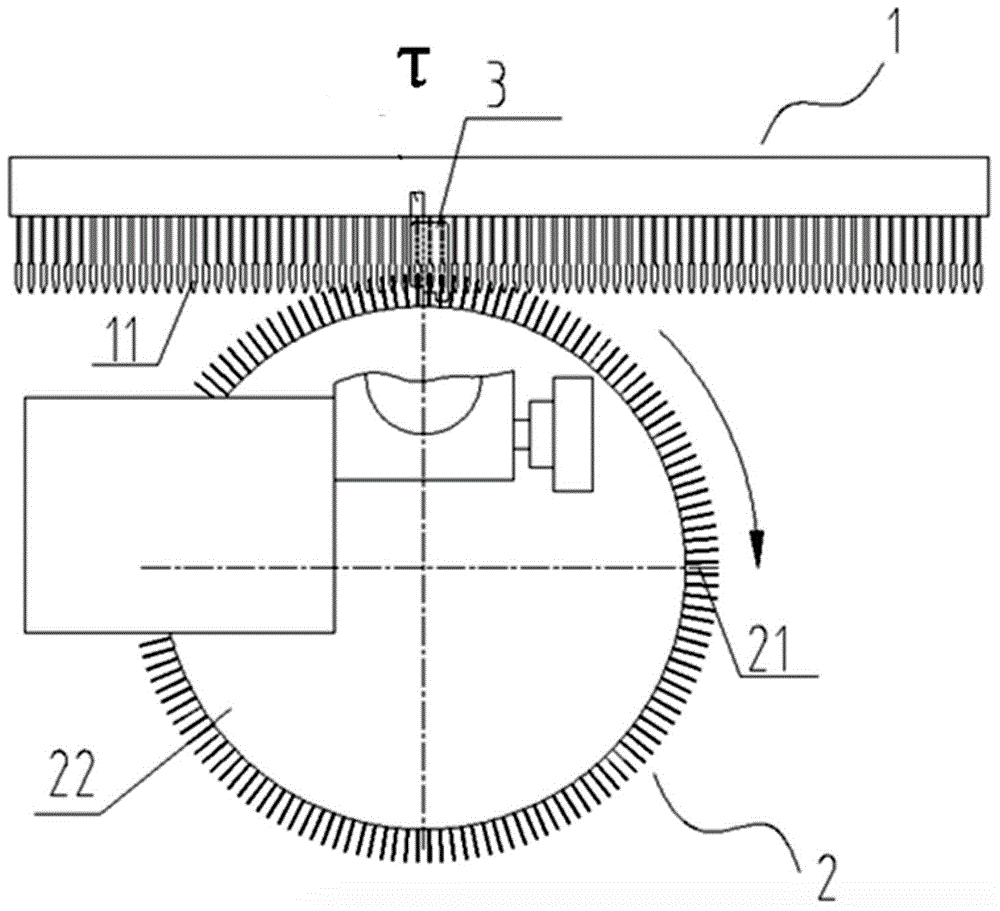

[0033] This application is aimed at figure 1 、 figure 2 and picture The automatic target transfer device shown in 16 is designed.

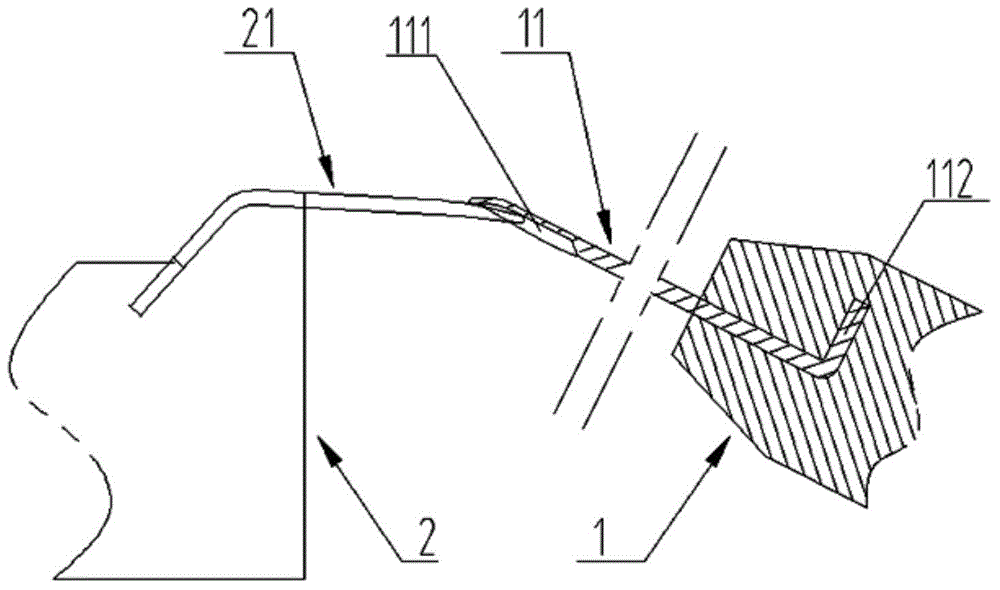

[0034] like figure 1 and figure 2 The first coil automatic eye-to-eye transfer device shown has a sewing machine 2 and a transfer needle plate 1. The sewing machine 2 has a rotating needle plate 22 and grooved needles 21 uniformly distributed along the needle plate. The transfer needle plate 1 is set At the tangential position on one side of the sewing machine dial 22 ( figure 1 shown at the τ position), and can move laterally along the tangential direction, on which a number of parallel and evenly distributed transfer needles 11 are arranged, and the push plate 3 is arranged at the docking position of the transfer needle 11 and the grooved needle 21 (at the τ position above the transfer needle 11, at the docking position, the transfer needle 11 is docked with the grooved needle 21, such as image 3 .

[0035] The rotation of the need...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com