Anodic alumina alloy section bar

An aluminum alloy profile and anodizing technology, which is applied in the field of metal materials, can solve the problem that the properties of anodized aluminum alloy profiles are not optimal, and achieve the effects of eliminating harmful effects, optimizing components, and refining recrystallized grains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

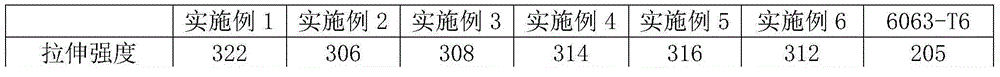

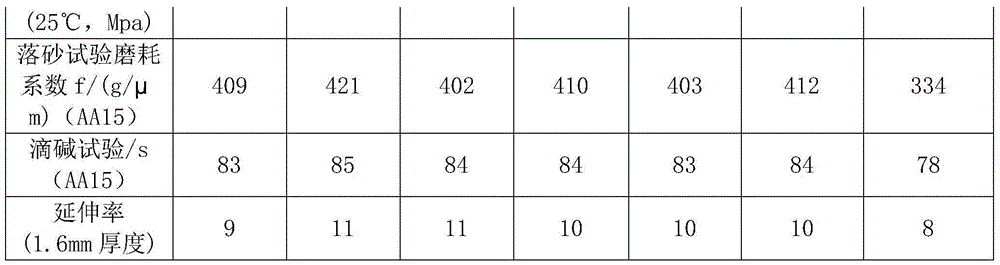

Examples

Embodiment 1

[0018] S1: Weighing each raw material for melting and casting to obtain an ingot;

[0019] S2: Extrusion: After the ingot obtained in S1 is homogenized, the car skin is removed, and extrusion is carried out on a hydraulic press. Before extrusion, the extrusion cylinder, extrusion die and ingot are heated. After extrusion, the profile is Cool down to below 50°C, stretch and straighten the profile, and then heat treatment. The heating method of the extrusion barrel is: raise the temperature to 90°C and keep it for 0.6h, then raise the temperature to 195°C and keep it for 0.7h, then raise the temperature to 300°C and hold it for 0.6h. After heat preservation for 0.9h, heat up to 385°C and hold heat for 0.6h, then heat up to 475°C, place the extrusion die in a holding furnace at 490°C for 7 hours for heating, and place the ingot in a holding furnace for 1 hour at 460°C for heating , wherein, the deformation amount of stretch straightening is 3%, and the extrusion rate is 35m / min; ...

Embodiment 2

[0022] S1: Weighing each raw material for melting and casting to obtain an ingot;

[0023] S2: Extrusion: After the ingot obtained in S1 is homogenized, the car skin is removed, and extrusion is carried out on a hydraulic press. Before extrusion, the extrusion cylinder, extrusion die and ingot are heated. After extrusion, the profile is Cool down to below 50°C, stretch and straighten the profile, and then heat treatment. The heating method of the extrusion barrel is: raise the temperature to 120°C and hold it for 0.8h, then raise the temperature to 210°C and hold it for 0.6h, then raise the temperature to 310°C and hold it for 0.8h. After 1 hour of heat preservation, the temperature was raised to 390°C and held for 0.8 hours, then the temperature was raised to 470°C, the extrusion die was placed in a holding furnace at 480°C for 7 hours for heating, and the ingot was placed in a holding furnace for 2 hours at 510°C for heating. Among them, the deformation amount of stretching ...

Embodiment 3

[0026] S1: Weighing each raw material for melting and casting to obtain an ingot;

[0027] S2: Extrusion: After the ingot obtained in S1 is homogenized, the car skin is removed, and extrusion is carried out on a hydraulic press. Before extrusion, the extrusion cylinder, extrusion die and ingot are heated. After extrusion, the profile is Cool down to below 50°C, stretch and straighten the profile, and then heat treatment. The heating method of the extrusion barrel is: raise the temperature to 95°C and hold it for 0.5h, then raise the temperature to 195°C and hold it for 0.8h, then raise the temperature to 305°C and hold it for 0.5h. After heat preservation for 0.6h, heat up to 405°C and hold heat for 0.7h, then heat up to 470°C, place the extrusion die in a holding furnace at 460°C for 5 hours for heating, and place the ingot in a holding furnace at 450°C for 1.5h Heating, wherein, the deformation amount of stretching and straightening is 2.5%, and the extrusion rate is 40m / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com