Visible silver release dressing and preparation method thereof

A technology of nano-silver and silver compounds, which is applied in the processing of textile materials, liquid/gas/vapor textile material processing, medical science, etc. High bactericidal activity, effect of reducing the risk of excessive silver release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

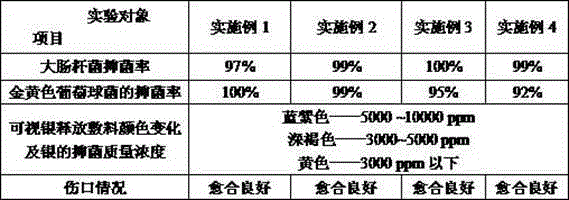

Examples

Embodiment 1

[0030] (1) Preparation of nano-silver solution: take 10L of newly configured 10% citric acid solution, 10L of 6mol / L sodium borohydride solution, and 1000L of 2mol / L silver nitrate solution and mix 1:1:100 at 25℃ Stir for 100 minutes, and then stand for 3 hours to obtain a nano silver solution. The size of the nano silver particles ranges from 1 to 100 nm; this example only provides the case where the silver compound is silver nitrate. Of course, the silver compound can also be silver sulfate, One or more of silver sulfadiazine and sodium zirconium phosphate;

[0031] (2) Prepare the tryptophan mixture solution: configure the tryptophan solution with a mass fraction of 10% and the HCOOH-HCL solution with a molar concentration ratio of 1:1 to mix at a volume ratio of 1:5 to obtain 50L tryptophan mixture Solution: Tryptophan solution can be one or two of L-tryptophan and D-tryptophan;

[0032] (3) Preparation of padding solution: mix the tryptophan mixed solution prepared in step 2 ...

Embodiment 2

[0036] (1) Preparation of nano-silver solution: Take 10L of newly configured 5% citric acid solution, 10L of 3mol / L sodium borohydride solution, and 800L of 1mol / L silver nitrate solution and mix 1:1:80 at 50°C Stir for 70 minutes and then stand for 3 hours to obtain a nano silver solution, in which the size of the nano silver particles ranges from 1 to 100 nm; this example only provides the case where the silver compound is silver nitrate. Of course, the silver compound can also be silver sulfate, One or more of silver sulfadiazine and sodium zirconium phosphate;

[0037] (2) Prepare the tryptophan mixture solution: mix the tryptophan solution with a mass fraction of 5% and the HCOOH-HCL solution with a molar concentration ratio of 1:1 in a volume ratio of 1:5 to obtain 50L tryptophan mixture Solution: Tryptophan solution can be one or two of L-tryptophan and D-tryptophan;

[0038] (3) Preparation of padding solution: mix the tryptophan mixed solution prepared in step 2 and the n...

Embodiment 3

[0042] (1) Preparation of nano-silver solution: take 10L of newly configured 1% citric acid solution, 10L of 1mol / L sodium borohydride solution, and 500L of 0.1mol / L silver nitrate solution and mix 1:1:50 at 70℃ After stirring for 40 minutes and then standing for 3 hours, a nano-silver solution is obtained. The particle size of the nano-silver particles ranges from 1 to 100 nm; this example only provides the case where the silver compound is silver nitrate. Of course, the silver compound can also be silver sulfate , One or more of silver sulfadiazine and sodium zirconium phosphate;

[0043] (2) Prepare the tryptophan mixture solution: configure the tryptophan solution with a mass fraction of 1% and the HCOOH-HCL solution with a molar concentration ratio of 1:1 to mix in a volume ratio of 1:5 to obtain 50L tryptophan mixture Solution: Tryptophan solution can be one or two of L-tryptophan and D-tryptophan;

[0044] (3) Preparation of padding solution: mix the tryptophan mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com