Tube bundle equipment and its use

A technology of equipment and pipelines, which is applied in the field of tube bundle equipment, and can solve problems such as pipeline deformation, difficult replacement of pipelines, and medium spillage into the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

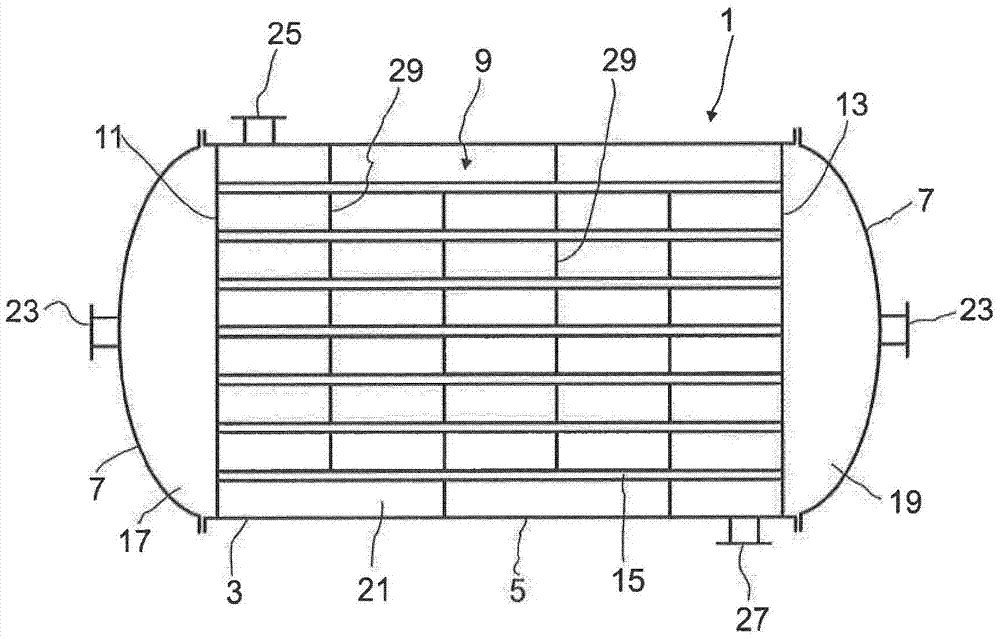

[0032] figure 1 The tube bundle equipment is shown in section.

[0033] The tube bundle arrangement 1 comprises a housing 3 which has a housing 5 which is closed at both ends by a cover 7 . The housing 5 is generally cylindrical here, but it can also have any other cross-section besides a circular cross-section.

[0034] The top cover 7 is usually fastened to the housing 5 respectively by means of a flange connection.

[0035] A tube bundle 9 is accommodated in the housing 3 . The tube bundle 9 comprises a first tube base 11 , a second tube base 13 and pipes 15 . The pipes 15 are here fastened with their ends in one of the two pipe bases 11 , 13 . In this case, the pipes 15 are preferably fixed in the tube bases 11 , 13 in such a way that they each end flush with the tube bases 11 , 13 . This prevents liquid from standing on the tube floor and not being able to flow into the pipe 15 during the vertical operation of the tube bundle arrangement 1 .

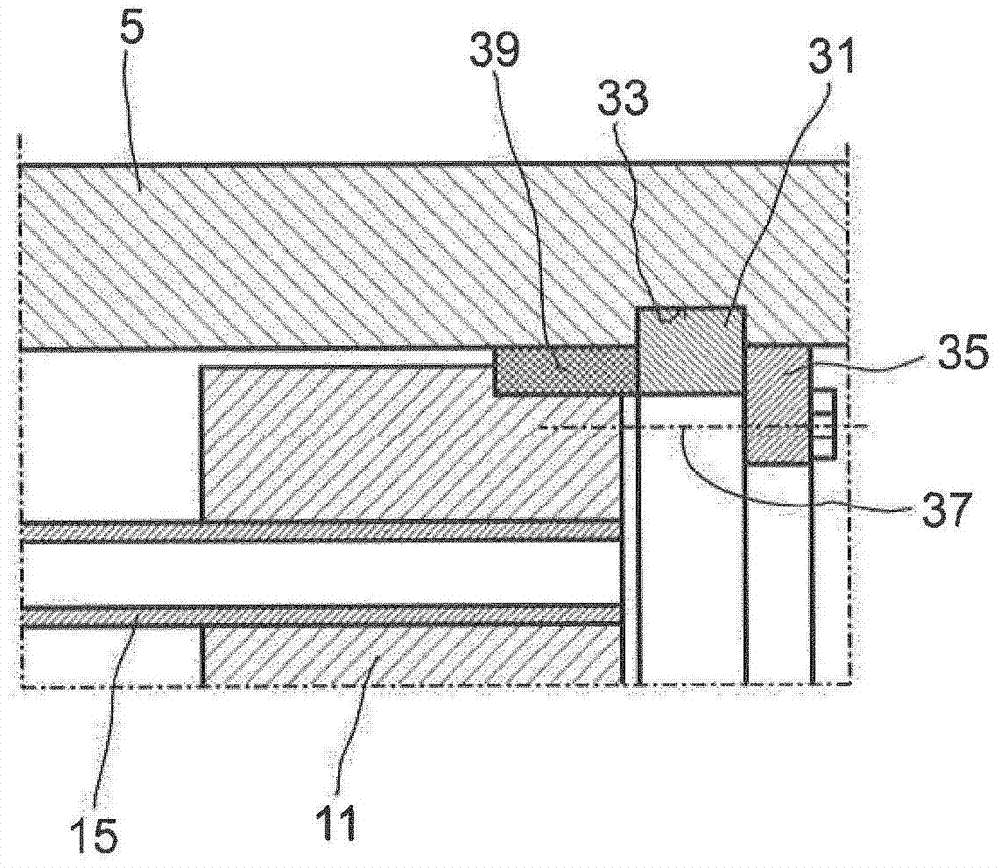

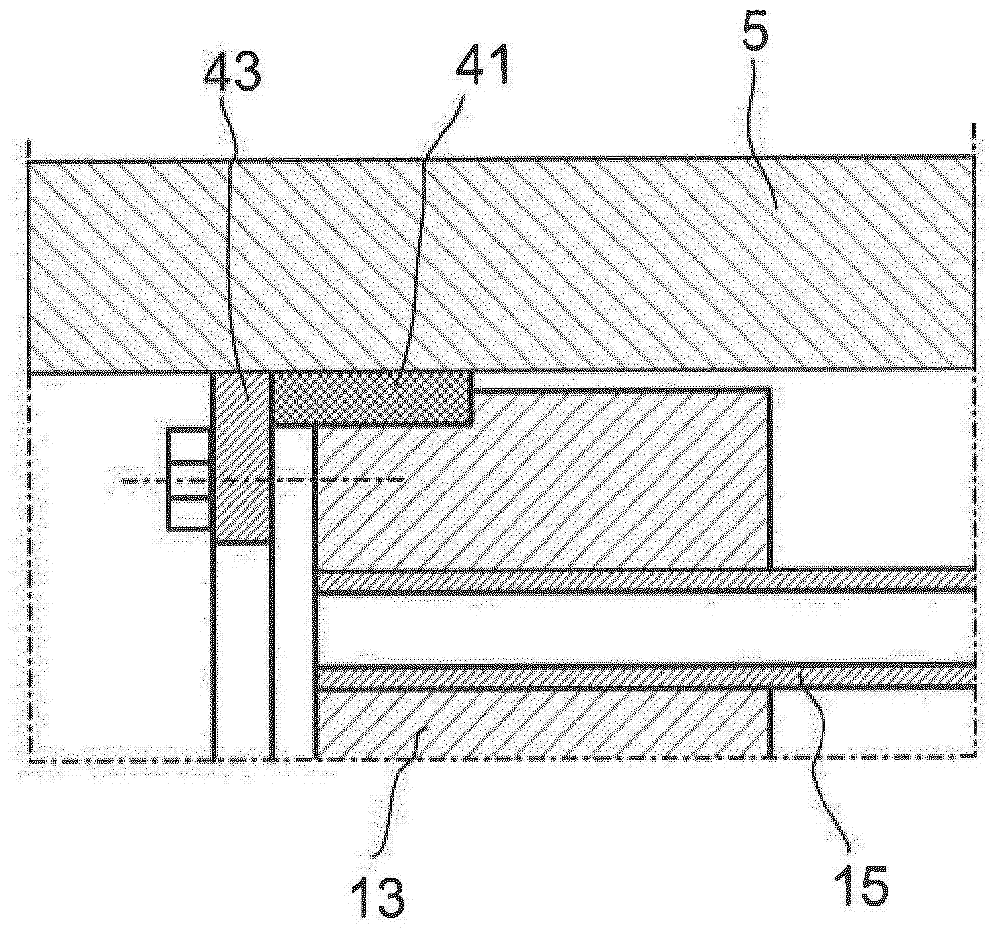

[0036] The tube bases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com