Frame sealing glue combination, display panel, preparation method of display panel and display device

A technology of display panel and frame sealing glue, applied in rare earth metal halide, rare earth metal fluoride, optics and other directions, can solve the problems of contamination of peripheral liquid crystal, peripheral defects, line afterimage, etc., and achieve the effect of avoiding liquid crystal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

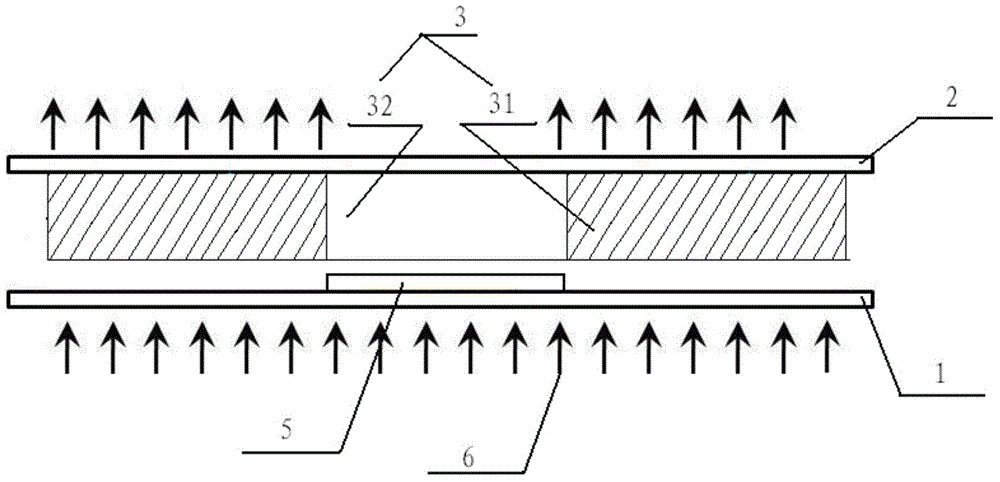

[0031] like figure 2 As shown, this embodiment provides a frame sealant composition 33, including a frame sealant and a light-wave conversion material 4 uniformly dispersed in the frame sealant, and the light-wave conversion material 4 can convert incident light into the frame sealant The incident light 6 is converted into curing light 7 for curing the sealant.

[0032] The frame sealant composition 33 provided by the present invention includes the light wave conversion material 4 in the frame sealant composition 33, and the light wave conversion material 4 can convert the incident light 6 into curing light 7 for curing the frame sealant, The frame sealant that is not irradiated by the incident light 6 can also be cured by the light converted by the light wave conversion material 4, thereby avoiding liquid crystal pollution, peripheral defects, and line afterimages caused by incomplete curing of the frame sealant during the pre-curing process. question.

[0033] Preferably,...

Embodiment 2

[0055] This embodiment provides a method for manufacturing a display panel, including the following steps:

[0056] The step of preparing the sealant composition;

[0057] A step of coating the sealant on the non-display area around the array substrate or on the color filter substrate corresponding to the non-display area around the array substrate;

[0058] The step of curing is carried out under the irradiation of incident light 6 .

[0059] Specifically, such as figure 2 as shown,

[0060] S1 Steps for preparing the frame sealant composition

[0061] The light conversion material and the sealant are uniformly mixed to form a sealant composition 33 .

[0062] Mix the frame sealant and light conversion material at an appropriate mass percentage, for example, 0.5-5%. The above frame sealant and light conversion material can be selected according to specific application scenarios. For example, if the frame sealant includes UV-cured resin, and when the incident light 6 is ...

Embodiment 3

[0072] This embodiment provides a display panel, which is manufactured by combining and curing the above-mentioned frame sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com