Sample production apparatus and sample production method of layered rock-soil body sample

A rock and soil mass, layered technology, applied in the preparation of test samples, etc., can solve the problems of difficulty in controlling the density of soil mass, unfavorable control of the density of the lower layer, etc., and achieve the effect of accurate and reliable test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

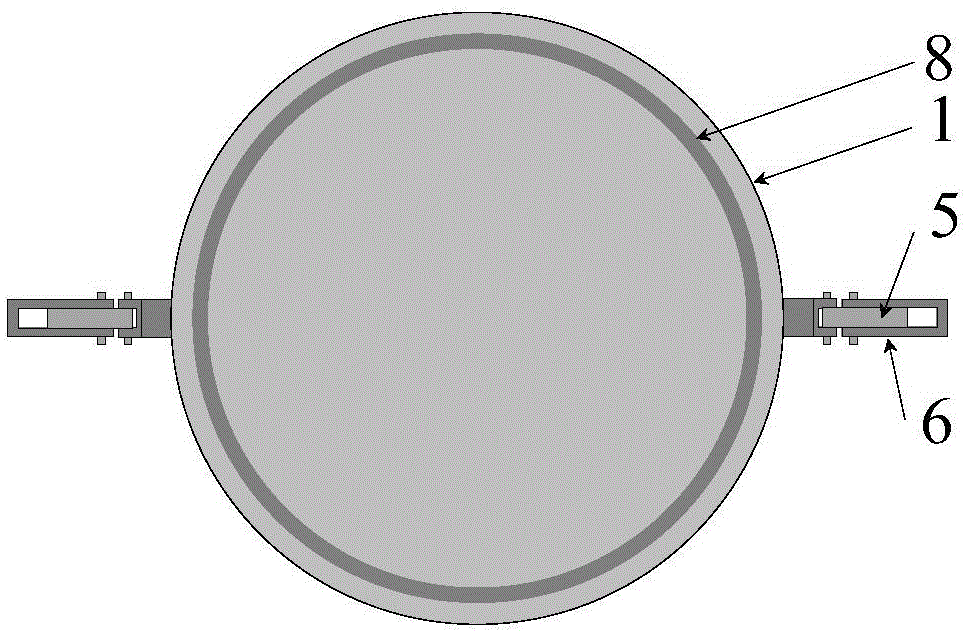

[0034] like Figure 1~6 As shown, a sample preparation device for layered rock and soil samples is characterized in that it includes: a first layer sample preparation device and a plurality of second layer sample preparation devices that are movably connected, and the first layer sample preparation device includes The sample preparation base 1, the universal cylinder 2 and the auxiliary cylinder 3 are movably connected sequentially from bottom to top; The two universal cylinders 2; the connecting surfaces of the movable connection are provided with an annular groove 8, and an "O"-shaped rubber gasket 4 is arranged in the annular groove 8.

[0035] The movable connection is through a snap lock connection.

[0036] The buckle lock includes a movable buckle 6 located at one end of the connecting surface, and the other end of the connecting surface is provided with a buc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com