Experimental device for simulating hydrofracture action mechanism in steam assisted gravity drainage (SAGD) process

A technology of action mechanism and experimental device, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., to achieve the effect of strong pertinence and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

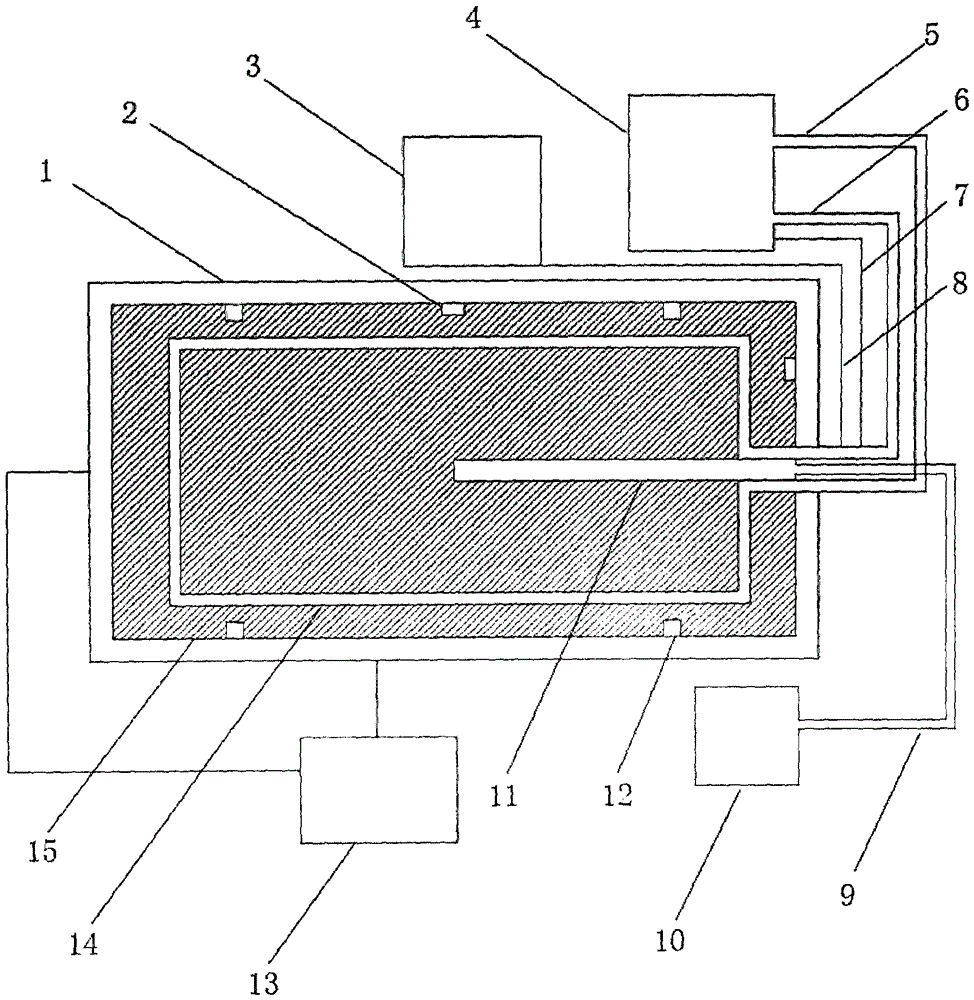

[0024] Embodiment 1: as figure 1 The present invention discloses an experimental device for simulating the action mechanism of hydraulic fracturing in the SAGD process, including a true triaxial stress loading device, a steam heating device, a fracturing device and an acoustic emission monitoring device.

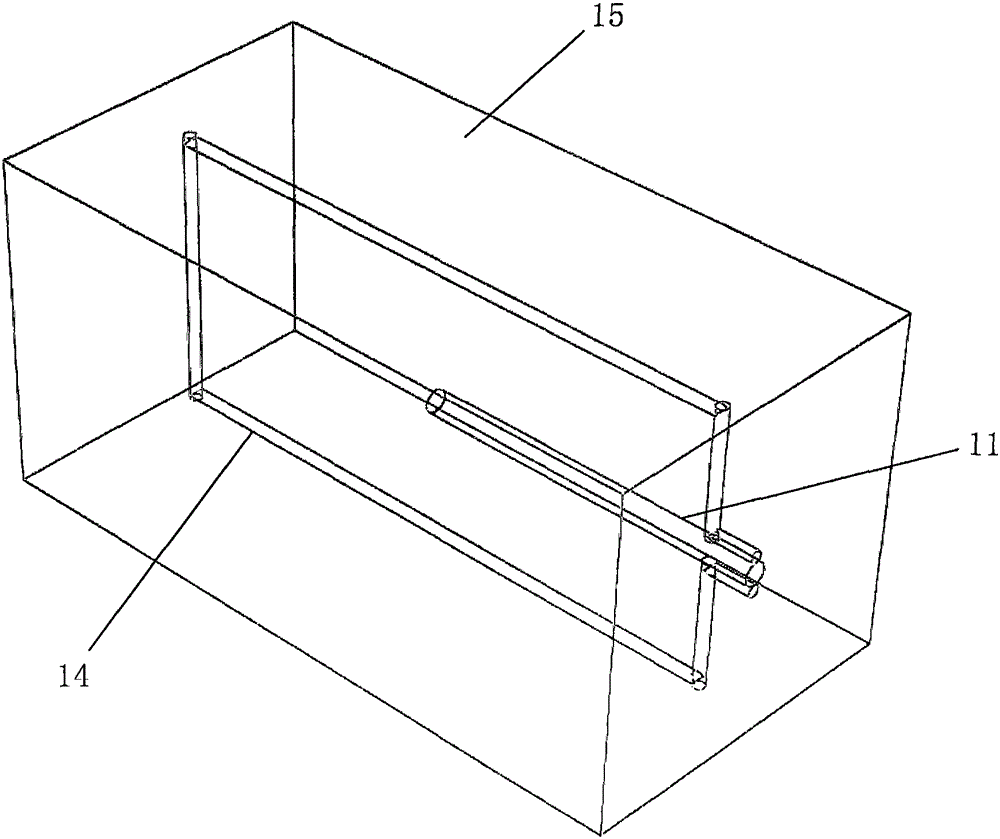

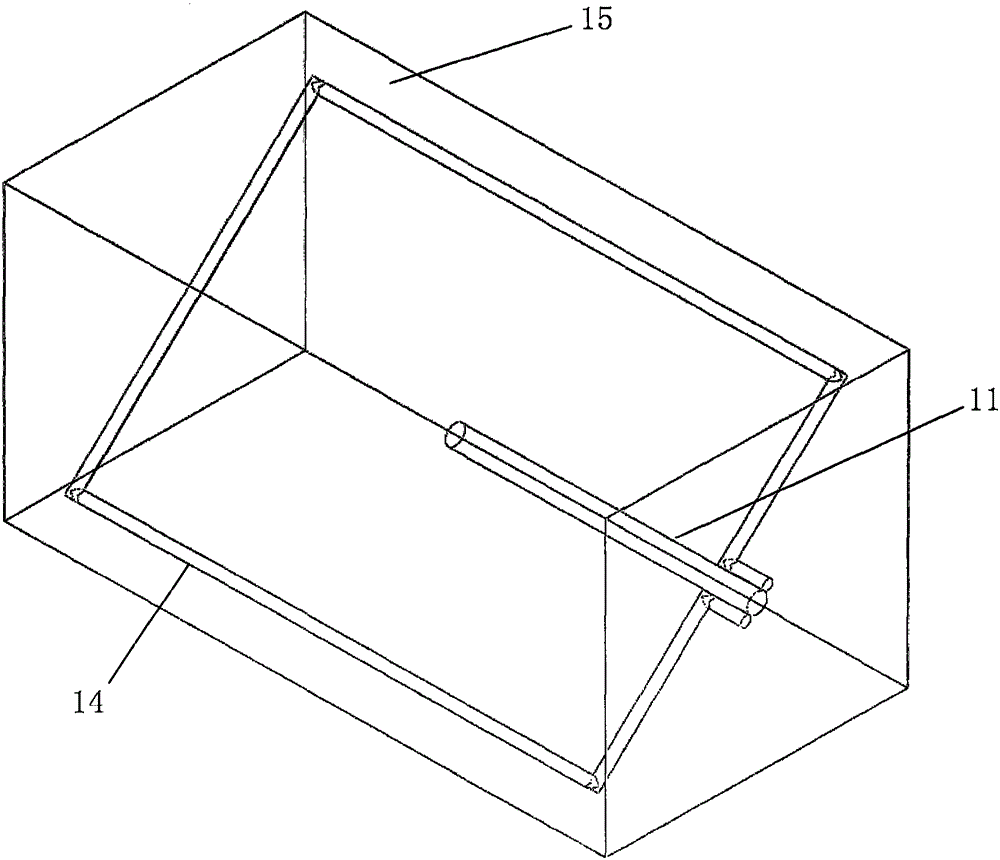

[0025] combine figure 1 As shown, the present invention relates to the experimental rock sample 15 which is a 300mm×300mm×600mm experimental rock sample 15 formed by pouring cement mortar. When pouring the cement mortar test rock sample, the wellbore 11 and the hot steam circulation pipeline 14 need to be placed in the iron mold in advance and poured together. When pouring, the outlet of the wellbore 11 is placed at the center of the experimental rock sample, and the position of the hot steam circulation pipeline 14 can be flexibly placed according to the requirements and purposes of the experiment. Lead out from the right side of the sample.

[0026] combine figure 1 As...

Embodiment 2

[0041] Embodiment 2: An experimental device for simulating the mechanism of hydraulic fracturing in the SAGD process. The difference from Embodiment 1 is that the heating rate of the steam heat source 4 is 40° C. / h.

Embodiment 3

[0042] Embodiment 3: An experimental device for simulating the mechanism of hydraulic fracturing in the SAGD process. The difference from Embodiment 1 is that the heating rate of the steam heat source 4 is 60° C. / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com