Fixed point clutch shifting rod mechanism of slide wire

A sliding contact line and rod mechanism technology, which is applied to the control mechanism, power control mechanism, building structure, etc. of the wing fan, and can solve the problems affecting the normal operation of the side turnstile, damage to wires and cables, and unstable power supply contact. , to achieve the effect of solving unstable power supply contact, reducing maintenance rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

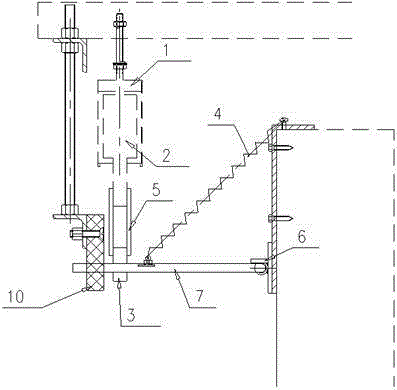

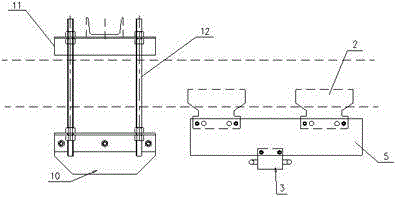

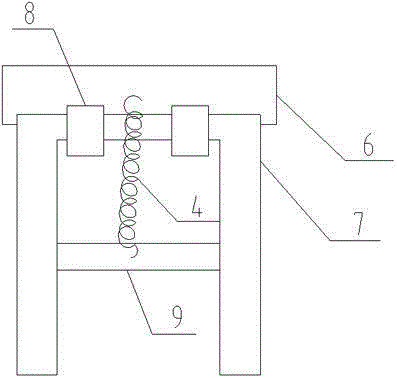

[0013] Such as Figure 1-3 An embodiment of the fixed-point clutch and lever mechanism of a sliding contact line of the present invention is shown: including the sliding contact line 1, the current collector 2, the drive block 3, the limit block 10 and the dial-back device. The collector 2 and the driving block 3 are provided with a clamping plate 5 on the outside. The collector 2 slides in the sliding contact line 1. A fixing plate 11 is provided at the upper end of the sliding contact line 1, and the limit stop 10 passes The connecting shaft 12 is connected with the fixed plate 11, the dial-back device is connected to the door leaf through the base 6, the driving block 3 is clamped on the dial-back device, and the dial-back device includes a U-shaped lever 7 and a connection A ring 8, the U-shaped lever 7 is connected to the base 6 through a connecting ring 8, a cross bar 9 is provided on the U-shaped lever 7, and one end of a tension spring 4 is connected to the cross bar 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com