High-water-tank full-automatic ultrafast washing machine

A washing machine and fully automatic technology, applied in the field of washing machines, can solve the problems of high noise when adding water and long time for water filling, and achieve the effect of reducing noise when adding water and shortening the time for adding water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

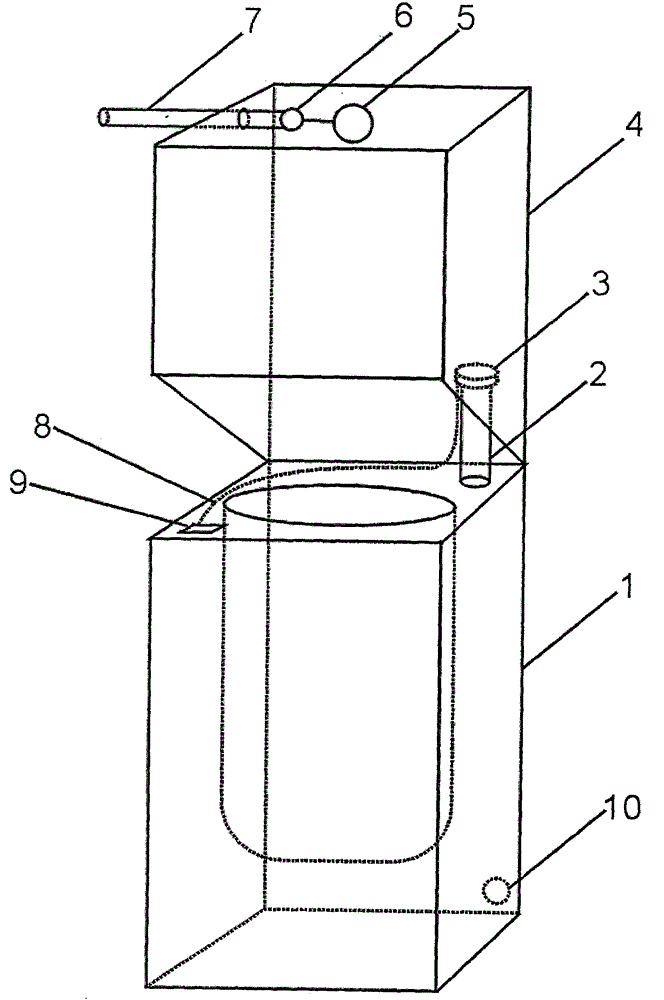

[0017] figure 1 The specific implementation manner of the high water tank fully automatic ultra-fast washing machine of the present invention is shown. The main body of the washing machine 1 is provided with a replenishment bucket 4, the thick water replenishment pipe 2 is controlled by the replenishment valve 3 and the circuit board 9 to add water to the main body of the washing machine 1, and the water inlet pipe 7 is controlled by the float 5 and the water inlet valve 6 to add water to the replenishment barrel 4. The transmission line 8 connects the circuit board 9 and the water supply valve 3 , and the water in the main body of the washing machine 1 is discharged from the drain port 10 .

[0018] When the washing machine main body 1 was not working, the water inlet valve 6 controlled by the float 5 had already filled up the water filling bucket 4.

[0019] When the washing machine main body 1 entered the water adding program, the circuit board 9 opened the water replenish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com