A material head device for automatic glass tube clamping of automatic bottle feeding machine

A glass tube, automatic technology, applied in glass forming, glass re-forming, glass manufacturing equipment, etc., can solve the problems of glass scratching hands, large loss of workers, and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

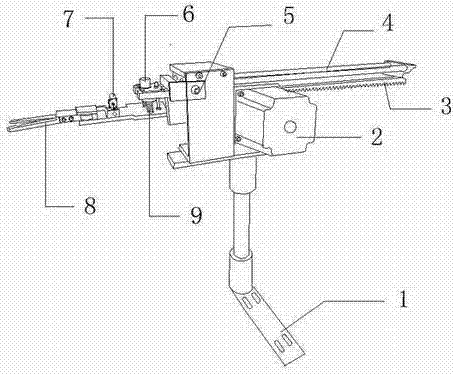

[0009] exist figure 1 Among them, the L-shaped support base 1 and the stepping drive motor 2 are connected to the supporting base plate, and the stepping drive motor 2 is connected to the rack 3 for back and forth transportation. The left side of the L-shaped support base 1 is the same as the base plate. The position is connected with the U-shaped board, an infrared sensor switch 5 is installed on the U-shaped board, the precision guide shaft 4 is fixed on the U-shaped board with a sleeve, the fixed module of the precision guide shaft 4 is connected with the rack 3 as a whole, and is used for Back and forth conveying prepares for the V-shaped clamping shear 8 clamping action; then the V-shaped clamping shear 8 is connected with the push-pull electromagnet 6 and the spring connector 9, which is used for the overall instantaneous displacement, and the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com