A mechanical structure for automatic folding of long stockings and its folding method

A technology of mechanical structure and long stockings, applied in packaging and other directions, can solve problems such as no occurrence, and achieve the effects of reducing labor intensity, improving folding efficiency and quality, and using simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

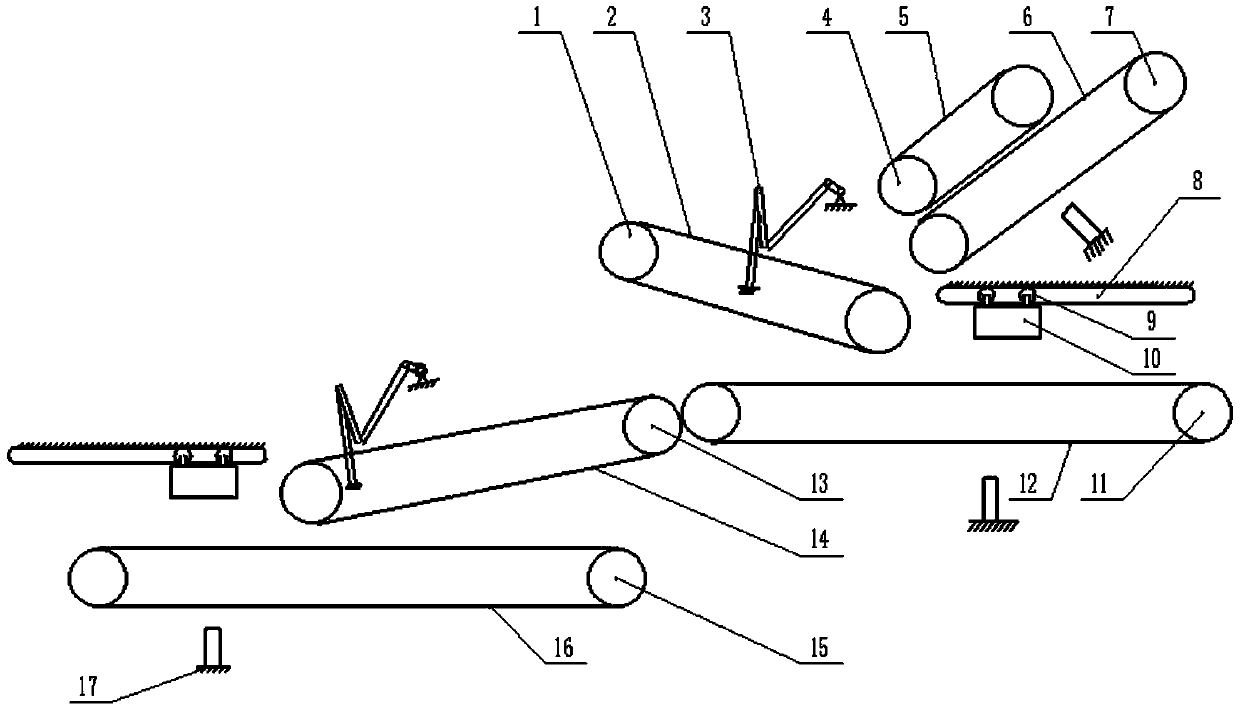

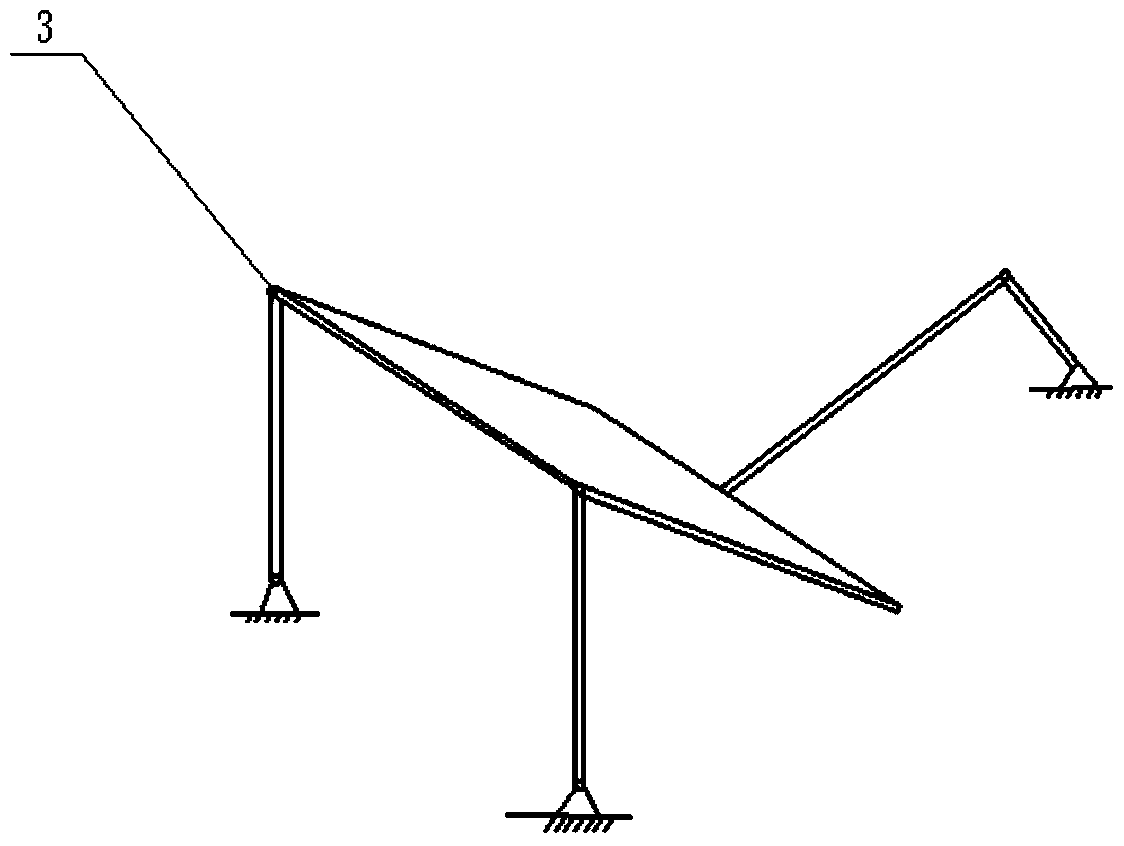

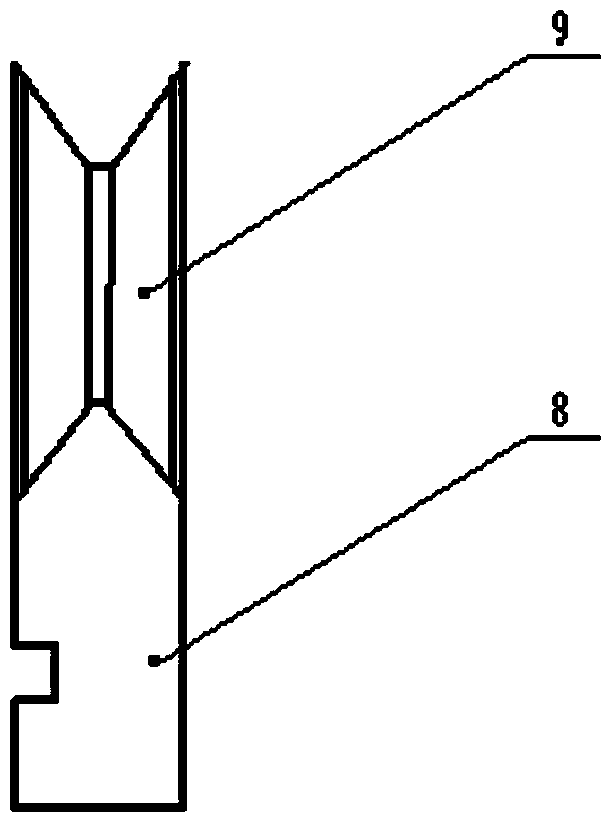

[0032] Such as Figure 1-3 As shown, a mechanical structure for automatically stacking long stockings includes a first pulley 1, a first conveyor belt 2, a crank mechanism 3, a second pulley 4, a second conveyor belt 5, a third conveyor belt 6, a third pulley 7, and a Inner cardboard mechanism, fourth pulley 11, fourth conveyor belt 12, fifth pulley 13, fifth conveyor belt 14, sixth pulley 15, sixth conveyor belt 16 and photoelectric sensor 17;

[0033] The first conveyor belt 2 is tightly sleeved on the first pulley 1, the second conveyor belt 5 is tightly sleeved on the second pulley 4, the third conveyor belt 6 is tightly sleeved on the third pulley 7, and the fourth conveyor belt 12 is tightly sleeved on the fourth pulley. On the pulley 11, the fifth conveyor belt 14 is tightly sleeved on the fifth pulley 13, the sixth conveyor belt 16 is tightly sleeved on the sixth pulley 15, and the third conveyor belt 6, the fourth conveyor belt 12, and the sixth conveyor belt 16 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com