Ground clearance adjusting lifting system of four-wheel tractor

A technology of ground clearance and lifting system, which is applied in the direction of elastic suspension, suspension, control device, etc., can solve the problems of large limitations and limited ground clearance of tractors, and achieve the effect of improving ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

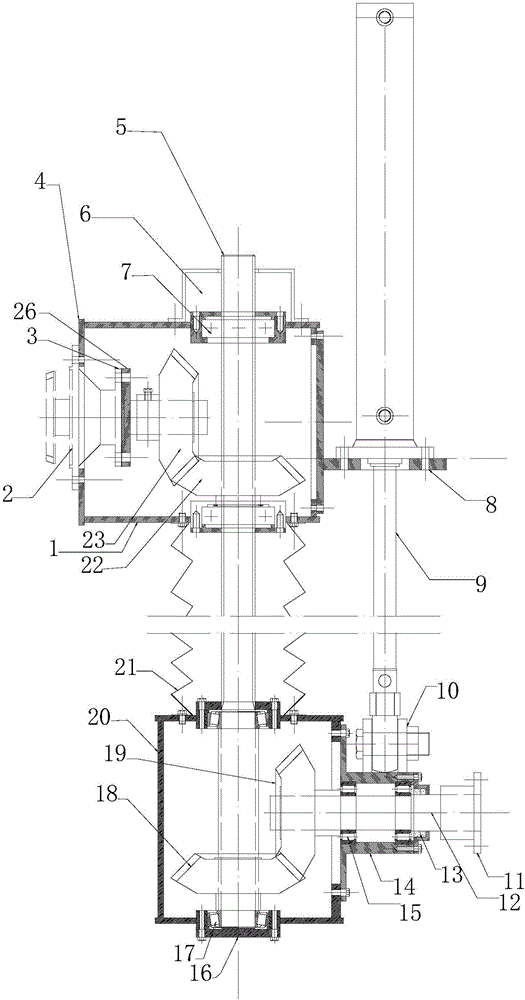

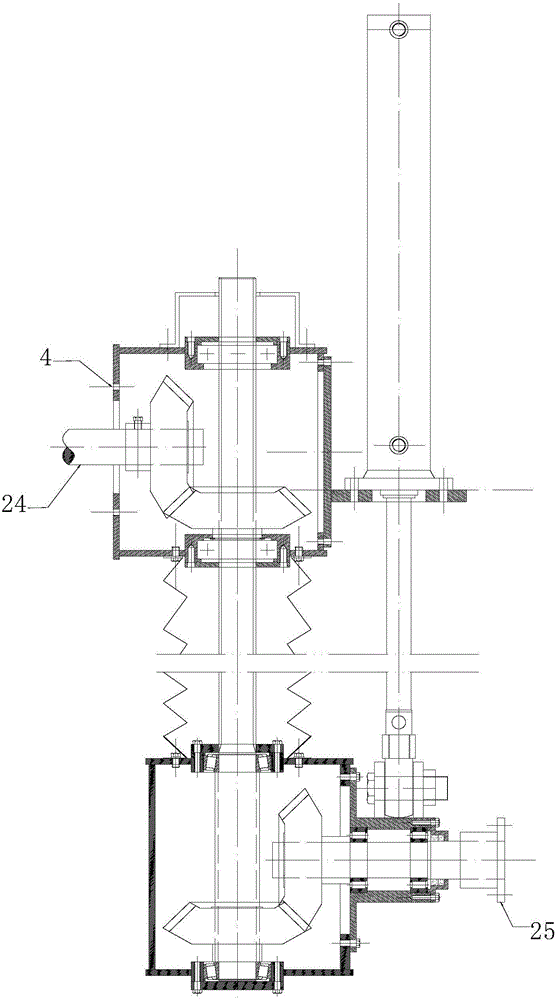

[0018] Such as figure 1 and figure 2 As shown, the four-wheel tractor ground clearance adjusting lifting system of the present invention includes a front wheel ground clearance adjusting lifting system and a rear wheel ground clearance adjusting lifting system. Such as figure 1 As shown, the front wheel ground clearance adjustment lifting system includes an upper box body 1 and a lower box body 20 , both of which are airtight, and the lower box body 20 is arranged below the upper box body 1 . The casing flange 4 on the side of the upper casing 1 facing the front wheel drive shaft is docked with the tractor front-drive steering wheel flange, and the tractor front-drive steering wheel flange is fixedly connected with the tractor front-drive steering component 2, so when the tractor turns, the tractor front-drive turns Part 2 can drive the upper box body 1 to turn. Bevel gear III 22 and bevel gear IV 23 are arranged inside the upper box 1, the shaft intersection angle of beve...

Embodiment 2

[0030] The difference from Embodiment 1 is that in this embodiment, the rear wheel ground clearance adjustment lifting system is connected to the steering component, and at this time, its box body flange 4 is docked with the tractor front drive steering wheel flange, and the bevel gear IV The hub of the tractor is connected to the drive shaft, and the drive shaft is docked with the tractor rear wheel drive disc.

[0031] Others are with embodiment 1.

Embodiment 3

[0033] The difference from Embodiment 1 is that in this embodiment, the ground clearance adjusting lifting system is a front wheel ground clearance adjusting lifting system, that is, no ground clearance adjusting lifting system is provided at the rear wheels. The ground clearance adjusting lifting system can also be a rear wheel ground clearance adjusting lifting system, that is, no ground clearance adjusting lifting system is provided at the front wheels.

[0034] Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com