Strong-flavor type tobacco product being nonflammable while heating and preparation method thereof

A heat-not-burn, tobacco product technology, applied in tobacco, tobacco processing, application, etc., can solve the problem that aroma components cannot be produced and released, and achieve rich and mellow wine aroma, reduce miscellaneous gas, and make up for the lack of aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

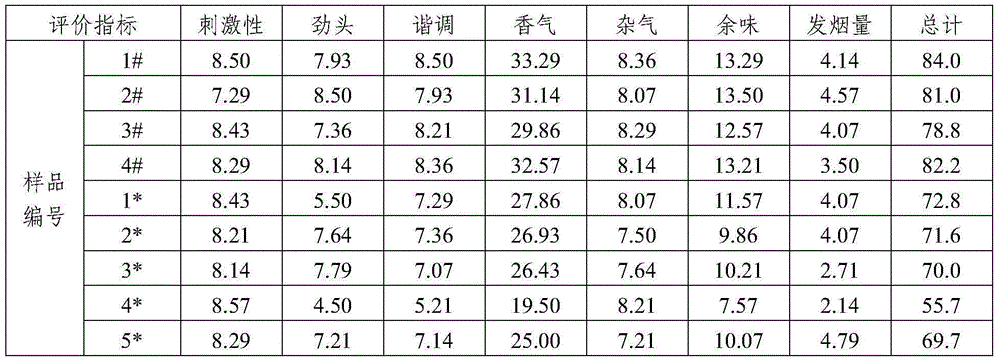

Embodiment 1

[0070] Example 1: A strong-flavored heat-not-burn tobacco product

[0071] 1. Its raw materials are calculated by mass percentage, including the following components: 3% flue-cured tobacco extract, 2% tobacco essence, 1.5% taste and flavor regulator, 2.5% Wuliangye, 15% glycerin, and 76% tobacco flakes, of which:

[0072] 1) The preparation steps of flue-cured tobacco extract are:

[0073] a. Take the Luzhou-flavor flue-cured tobacco leaves prepared in the wine cellar for cellar preparation (that is, to place the tobacco leaves in the wine cellar for more than half a year) and pulverize them with a pulverizer, and screen 40-100 mesh tobacco powder;

[0074] b Weigh 100g of tobacco powder into a 1L Erlenmeyer flask, add 300mL of ethanol, conduct ultrasonic extraction at 50±5°C for 4 hours, after standing and settling, first pass through a sand core funnel and then use a microporous filter with a pore size of 0.45μm The filtrate was obtained by membrane filtration, and the filt...

Embodiment 2

[0081] Example 2: A strong-flavored heat-not-burn tobacco product

[0082] 1. The raw materials are calculated by mass percentage, including the following components: 7% Burley tobacco extract, 4% tobacco essence, 4% flavor regulator, 1% Luzhou Laojiao, 13% glycerin, and 71% tobacco flakes ,in:

[0083] 1) The preparation steps of Burley tobacco extract are:

[0084] a get the burley tobacco leaves prepared in the wine cellar (the tobacco leaves are placed in the wine cellar for more than half a year) and pulverized by a pulverizer, and sieve 40-100 order tobacco powder;

[0085] b Weigh 100g 40-100 mesh smoke powder into a 1L Erlenmeyer flask, add 300mL ethanol, ultrasonically extract at 50±5°C for 4 hours, after standing and settling, first filter through a sand core funnel and then use a pore size of 0.45μm The filtrate is obtained by filtering with a microporous membrane, and the filtrate is concentrated by rotary evaporation under reduced pressure to obtain the primary ...

Embodiment 3

[0092] Example 3: A strong-flavored heat-not-burn tobacco product

[0093] 1. Raw materials are calculated by mass percentage, including the following components: 1% oriental tobacco tobacco extract, 1.5% tobacco essence, 0.5% taste and flavor regulator, 4% Jiannanchun, 3.5% glycerin, and 89.5% expanded shredded tobacco, of which:

[0094] 1) The preparation steps and conditions of oriental tobacco tobacco extract are the same as in Example 1.

[0095] 2) Tobacco flavor mainly consists of the following ingredients: macrostigmatrienone 4%, ethyl maltol 3%, ethyl vanillin 0.5%, palmitic acid 0.5%, dihydroactinolactone 0.2%, succinic acid Dimethyl isovaleric acid 0.1%, β-ionone 0.5%, benzyl alcohol 0.2%, vanilla extract 2%, ronal ether 4% and propylene glycol 85%; mix the above components on a vortex shaker .

[0096] 3) The mouthfeel and aroma regulator is mainly composed of the following components: ethyl acetate 13.68%, ethyl butyrate 3.42%, ethyl valerate 0.82%, ethyl capro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com