A mechanical automatic drip irrigation system

A mechanical and automatic irrigation technology, applied in the field of agricultural irrigation, can solve problems such as inability to work, and achieve the effect of no power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

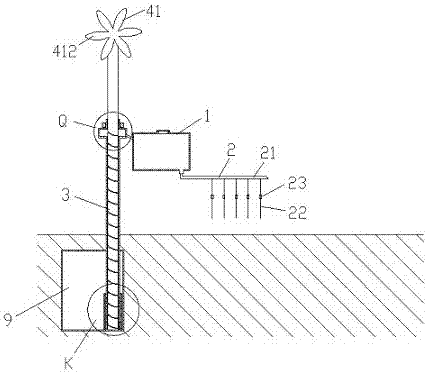

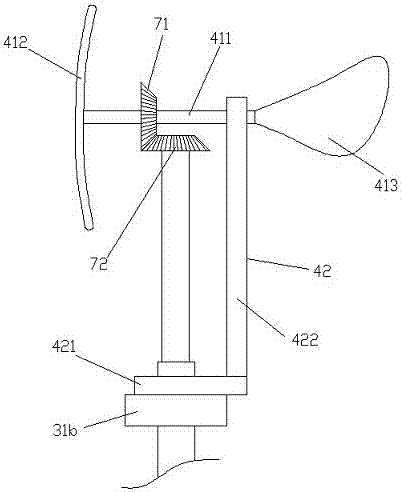

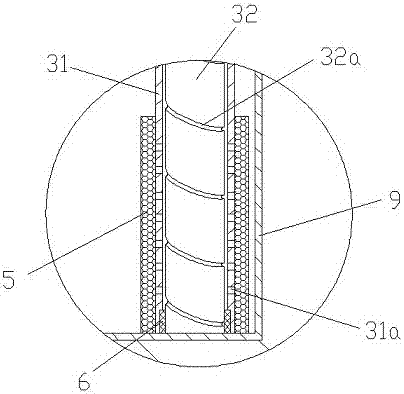

[0022] Figure 1 to Figure 5 It is a structural schematic diagram of the present invention.

[0023] The reference signs are: shaft sleeve A, needle bearing B, water tank 1, water tank port 1a, intake and exhaust port 1b, water inlet 1c, water tank outlet 1d, water tank cover 11, drip irrigation pipeline system 2, drip irrigation main pipe 21. Capillary drip tube 22, pipe clamp 23, water lifting device 3, water lifting pipe 31, water passing hole 31a, water collection chamber 31b, water lifting screw 32, spiral groove 32a, impeller assembly 41, rotating shaft 411, wind impeller 412, empennage 413, support rod assembly 42, turntable 421, support rod 422, filter device 5, thrust bearing 6, first bevel gear 71, second bevel gear 72, intermediate pipe 8, underground water tank 9.

[0024] Figure 1 to Figure 5 It is a structural schematic diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com