Chromatography precision detecting method and device

A detection method and precision technology, applied in measuring devices, optical devices, instruments, etc., can solve problems such as large errors in overprint accuracy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

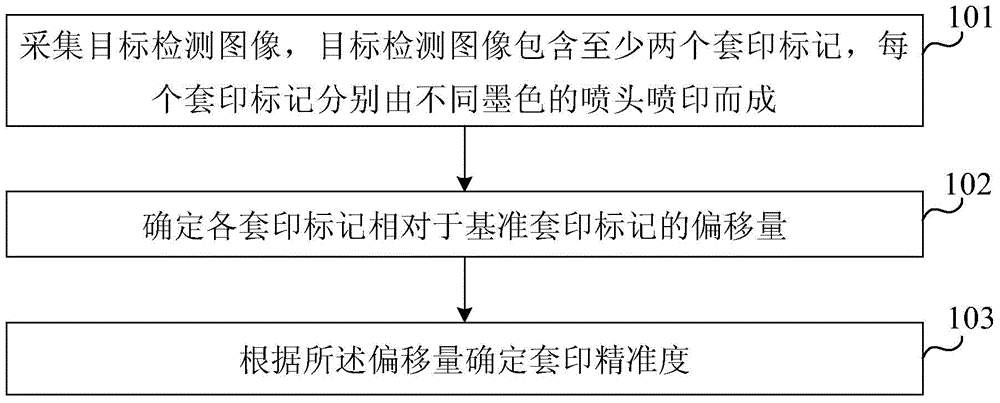

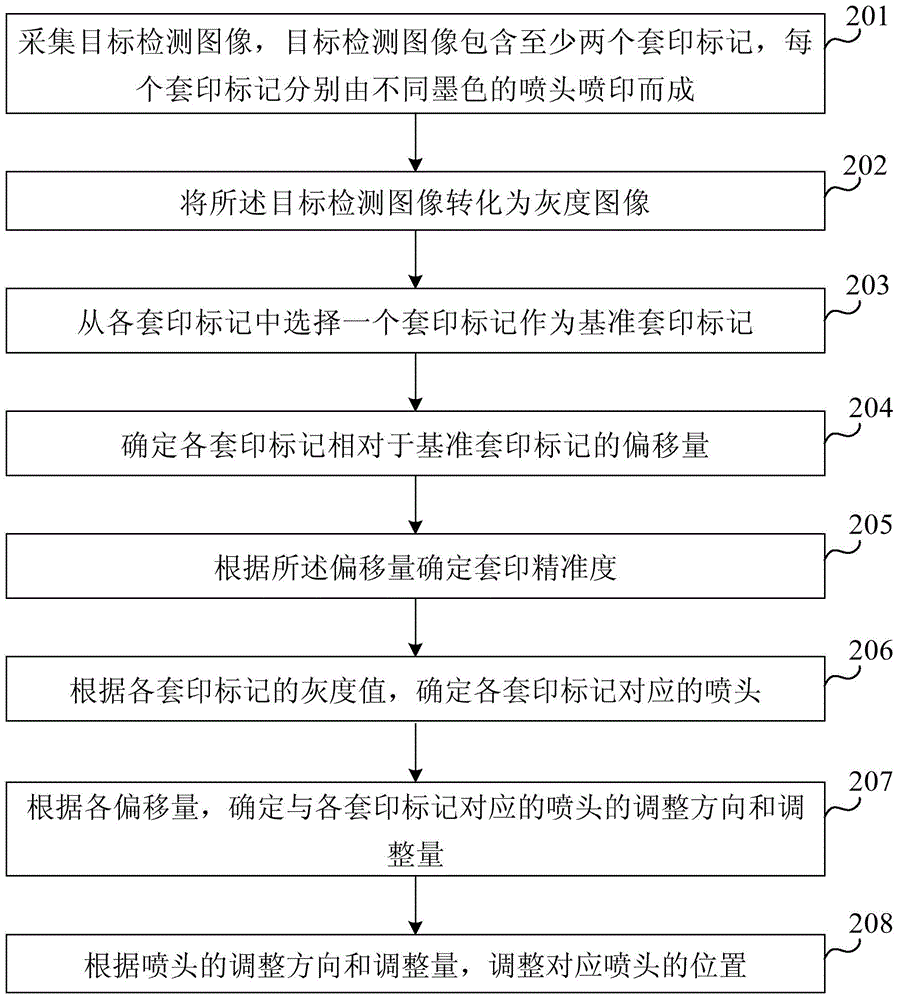

[0035] figure 1 It is a flow chart of Embodiment 1 of the overprint accuracy detection method of the present invention. Such as figure 1 As shown, the method of this embodiment may include:

[0036] Step 101, collect a target detection image, the target detection image includes at least two overprint marks, and each overprint mark is printed by a nozzle of a different ink color.

[0037] Specifically, in the overprinting process, for example, C (cyan), M (magenta), Y (yellow), K (black) four-color overprinting process, when the substrate passes through the four-color nozzles in sequence, the four-color nozzles will Prints an overprint mark at the same location on the substrate, usually at the edge of the substrate. The target detection image collected in this embodiment is the image containing the four-color overprint marks. The target detection image can be collected by an industrial camera light, and the collected target detection image can be input to a computer for anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com