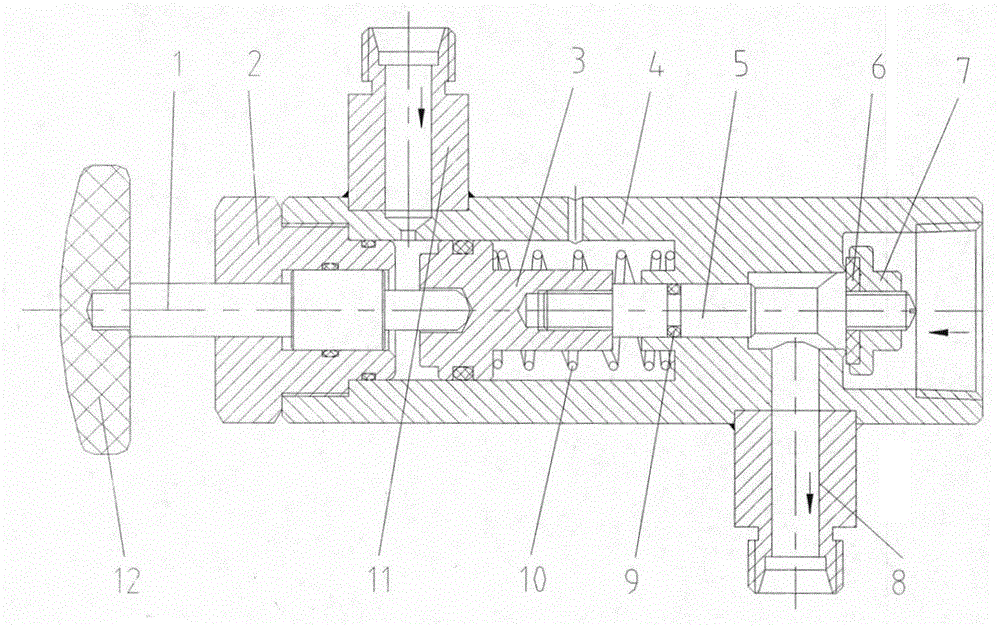

Relief valve

A release valve and valve body technology, which is applied in the field of release valves, can solve the problems that manual ball valves do not have automatic control functions and remote operation functions, water stain loss, and affect normal production, etc., so as to reduce maintenance workload and improve Rated working pressure, the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

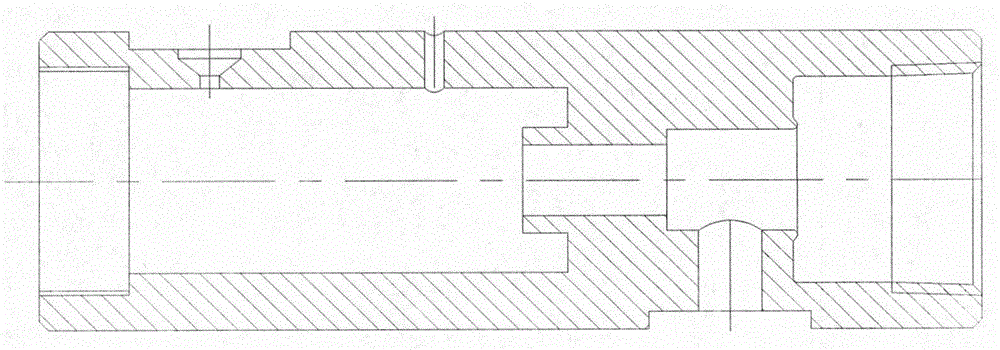

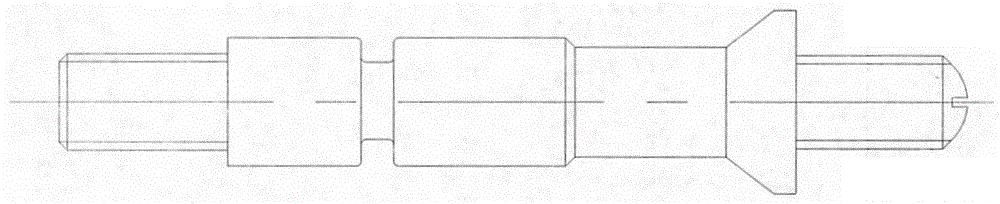

[0011] The gasket is embedded in the groove of the cover nut and tightened at the end of the main shaft. The O-ring is set in the outer groove of the main shaft and the piston. The main shaft and the piston are screwed and installed in the hole of the valve body; Between, the nut is tightened on the top of the valve body, sealed by the O-ring; the ejector rod is plugged in the nut, sealed by the O-ring, and the ejector head is inserted into the counterbore of the piston; the handle is screwed on the head of the ejector rod; the drive joint It is welded at the drive port of the valve body, and the output joint is welded at the output port of the valve body; the action mechanism of pressurized drive and spring reset is adopted, and the spring pushes the piston at ordinary times, so that the sealing gasket and the sealing convex ring of the valve body are contacted and sealed, and the fire water source is isolated ;When in action, the driving medium is led from the driving interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com