A feeding and discharging robot

A robot, feeding and discharging technology, which is applied in the field of pharmaceutical packaging machinery and food, can solve the problems of difficulty in ensuring the docking accuracy of the freeze-dried sheet and the feeding and discharging vehicle, the deviation of the docking position, and gaps, etc., so as to reduce equipment costs and install and debug The effect of saving time, achieving smooth transition, and reducing the rate of bottle falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

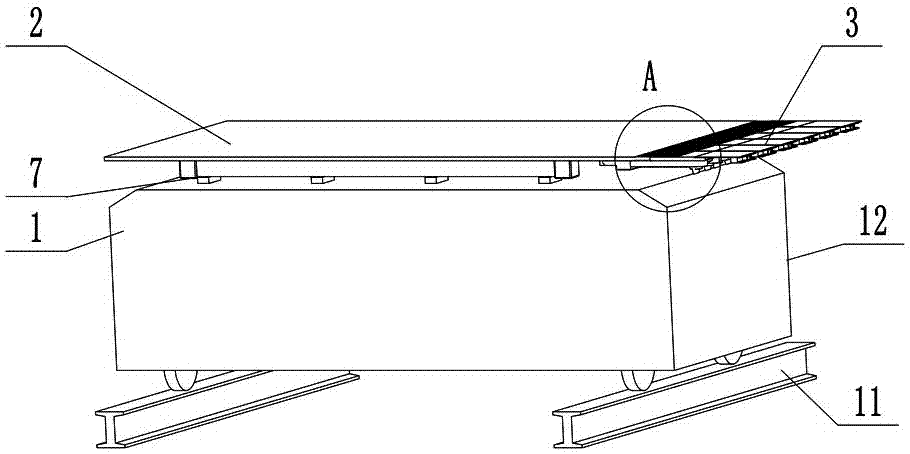

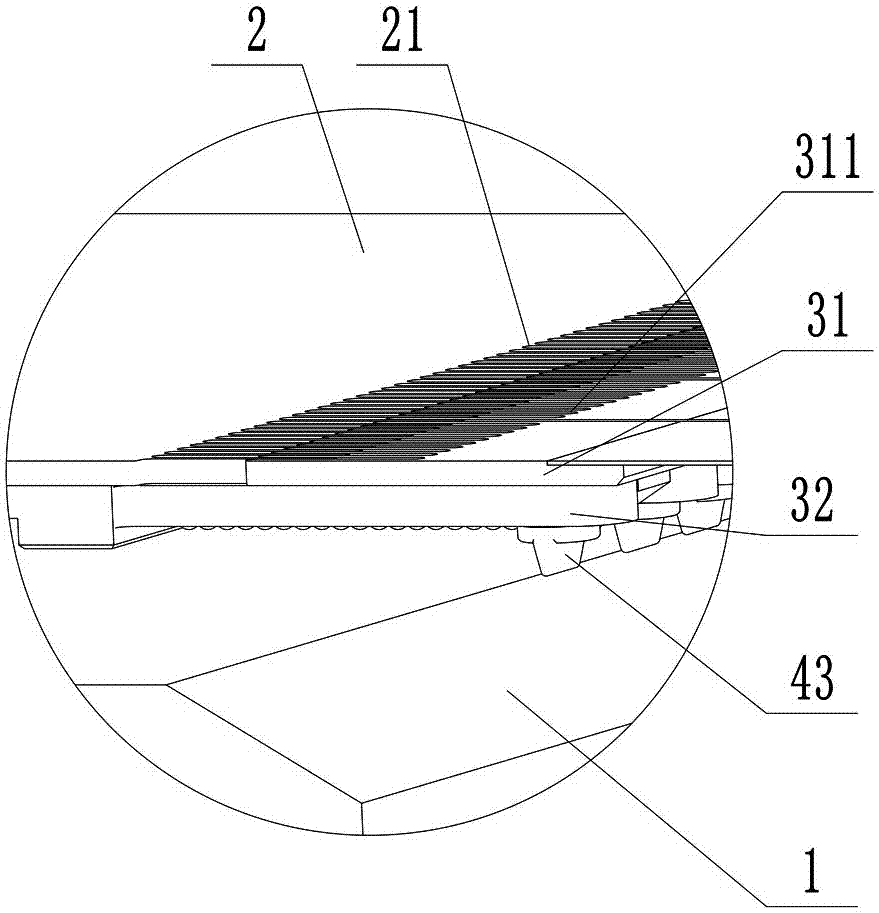

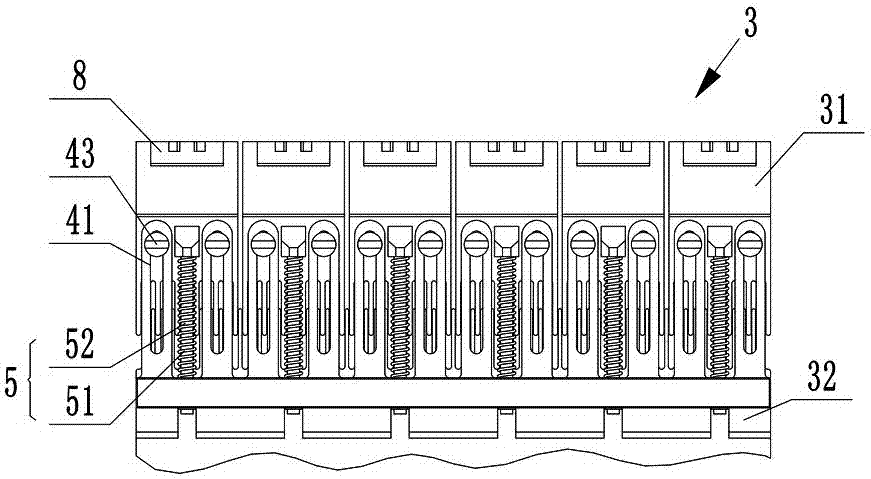

[0027] Such as Figure 1 to Figure 5 As shown, the feeding and discharging robot of this embodiment includes a base assembly 1 and a docking platform 2, the docking platform 2 is arranged on the base assembly 1, and the end of the docking platform 2 docked with the freeze-dried slab of the freeze-drying line is provided with multiple sets of docking Sub-module 3, multiple groups of docking sub-modules 3 are arranged in a straight line, multiple groups of docking sub-modules 3 can realize the segmented docking of the docking platform 2 and the freeze-dried plate layer, which effectively improves the docking accuracy and reliability, and realizes the bottle in and out Smooth transition during feeding, reducing the rate of bottle inversion; each group of docking sub-modules 3 includes a movable receiving plate 31 and a supporting plate 32, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com