Beam clamping and fixing device

A fixing device, clamping and fixing technology, which is applied in the directions of auxiliary devices, transportation and packaging, vehicle parts, etc., can solve the problem of heavy columnar structure of the beam body fixing platform, easy left and right sliding of the beam structure, and the space of the beam body clamping platform Limited and other problems, to achieve the effect of simple and convenient connection, simple structure, and light structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] For the convenience of description, the description of the relative positional relationship of each component (such as: upper, lower, left, right, etc.) is described according to the layout direction of the drawings in the specification.

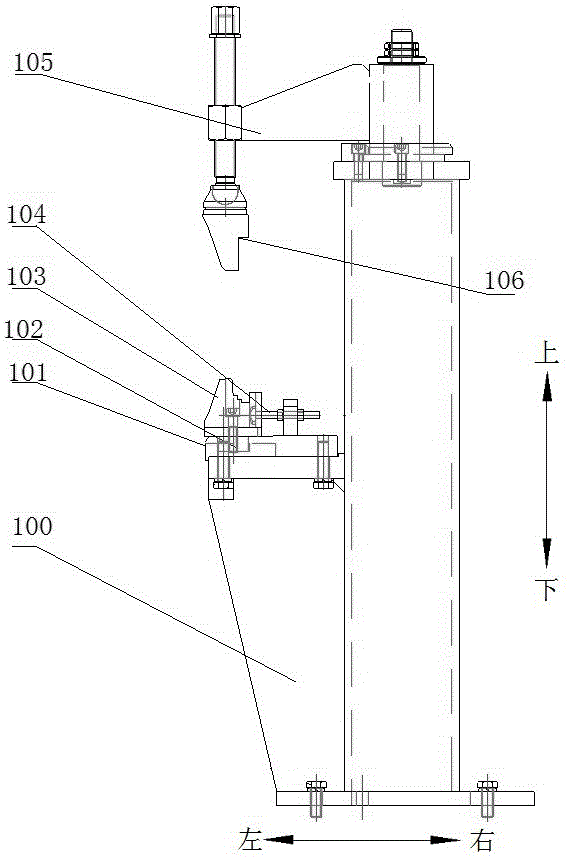

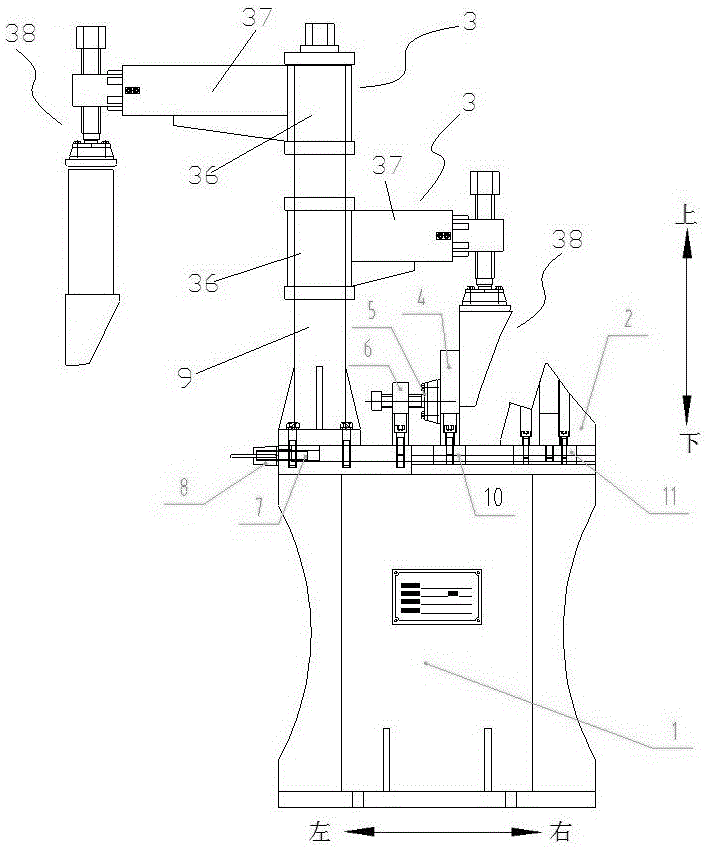

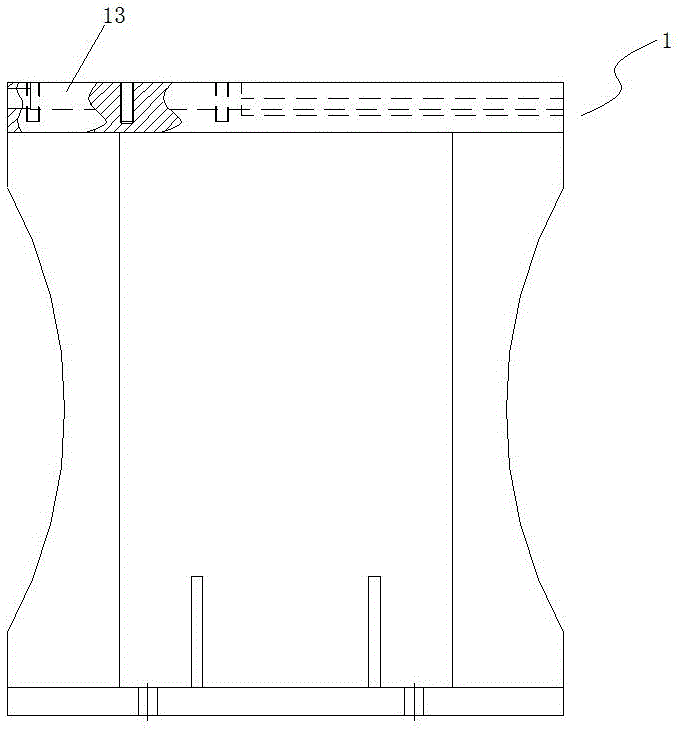

[0071] Such as Figure 2-18 As shown, a beam clamping and fixing device includes a base 1, a stand 9 fixed on one end of the upper surface of the base 1, two pressing arms 3 that are set at different heights on the stand 9 and can rotate relative to the stand 9, and Beam blocks 2 that can move horizontally on the base 1.

[0072] The pressing arm 3 includes a vertical arm 36 sleeved on the column 9, a telescopic horizontal arm 37 vertically fixed to the vertical arm 36, and a beam clamping head 38 vertically installed on the front end of the horizontal arm 37. The head 38 is parallel to the vertical arm 36 and movable in the vertical direction.

[0073] The horizontal arm 37 includes a cylinder sleeve 39 and a piston arm 40 sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com