Energy-storage backblowing filter, and filtration and filtration-regeneration method thereof

A filter regeneration and filter technology, which is applied to chemical instruments and methods, fixed filter element filters, filter separation, etc., can solve the problems of cumbersome operation and complex structure of backflushing filters, and achieve simplified equipment configuration and reduced project cost and the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

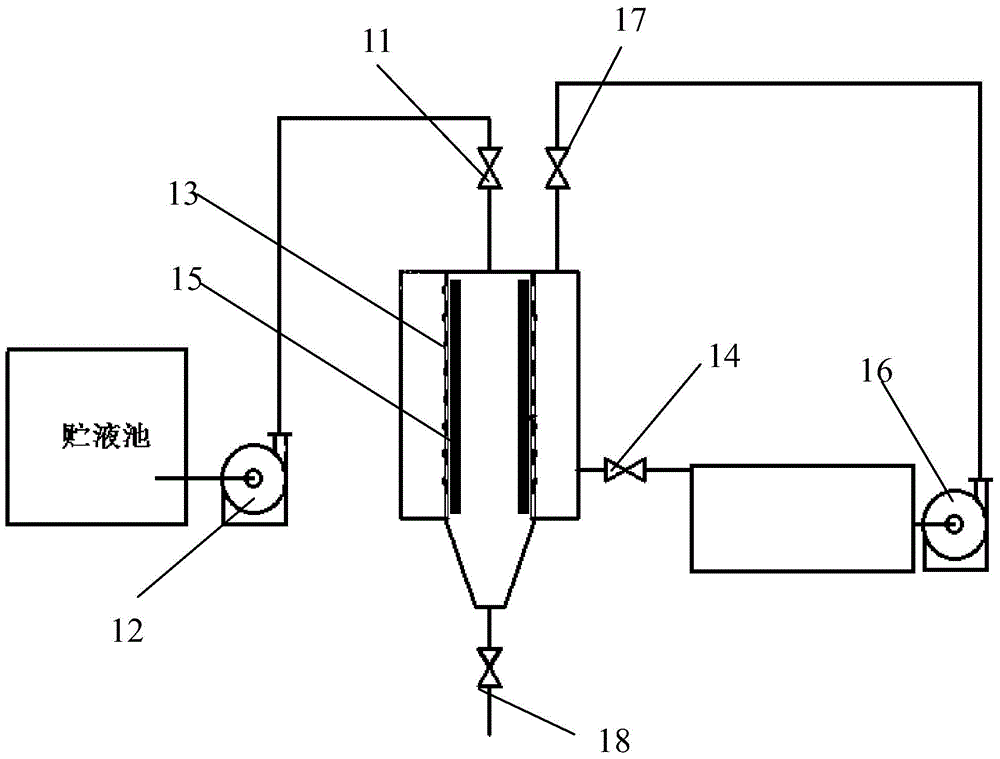

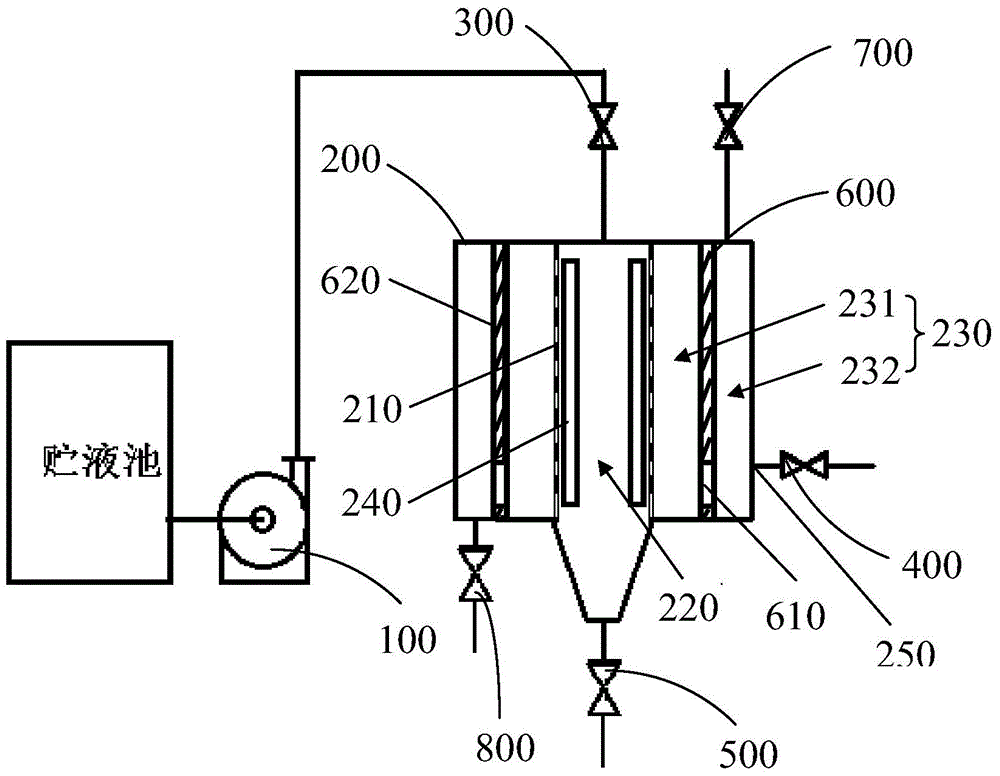

[0076] Such as image 3 As shown, an energy storage backflush filter according to an embodiment of the present invention includes a centrifugal pump 100 , a body 200 , a raw liquid inlet valve 300 , a filtrate outlet valve 400 and a filter cake outlet valve 500 . Wherein, the centrifugal pump 100 is connected with the raw liquid inlet valve 300 , and the raw liquid inlet valve 300 , the filtrate outlet valve 400 and the filter cake outlet valve 500 are respectively connected with the body 200 . The body 200 is provided with a filter screen 210, the filter screen 210 divides the internal space of the body 200 into a raw liquid space 220 and a filtrate space 230, the raw liquid inlet valve 300 and the filter cake discharge valve 500 communicate with the raw liquid space 220 respectively, and the filtrate The discharge valve 400 communicates with the filtrate space 230 .

[0077] In this embodiment, the energy-storage blowback filter is arranged vertically, and the raw liquid in...

no. 2 example

[0107] see Figure 7 The difference between the second embodiment of the present invention and the first embodiment is that the compressed air energy storage part is an energy storage structure 600' with a closed space, the bottom of the energy storage structure 600' is connected to the body 200', and the energy storage The upper space of the structure 600' is an energy storage space. The internal space of the energy storage structure 600' constitutes a part of the filtrate space 230' of the energy storage backflush filter.

[0108] Wherein, the bottom of the energy storage structure 600' can be connected to the top of the body 200' to seal the air in the upper space of the energy storage structure 600'.

[0109] The energy storage structure 600' can also be connected to the side wall of the body 200', wherein the bottom of the energy storage structure 600' is higher than the filtrate outlet 250', so that the air is enclosed in the upper space of the energy storage structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com