Fire trace tube type automatic nanometer powder-based dry powder fire extinguishing device

An automatic fire-extinguishing and fire-probe technology, applied in the field of fire-extinguishing, can solve the problems of long detection response time, time-consuming installation, complex structure, etc., and achieve the effects of good atomization, good diffusion and fast response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

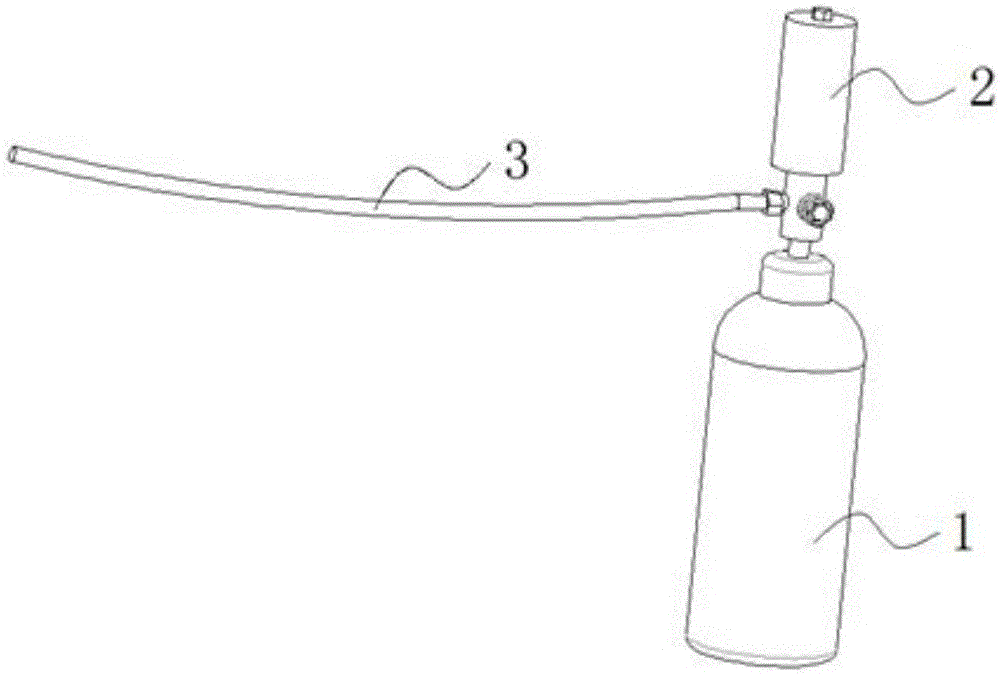

[0021] Embodiment one: as attached figure 1 with 2 , a fire detection tube type nano-powder-based dry powder automatic fire extinguishing device, comprising a nano-powder-based dry powder fire extinguishing agent storage tank 1, a container valve 2 and a fire detection tube 3, the container valve 2 and the nano-powder-based dry powder fire extinguishing agent storage tank 1 connected, the fire detector tube 3 is connected to the container valve 2.

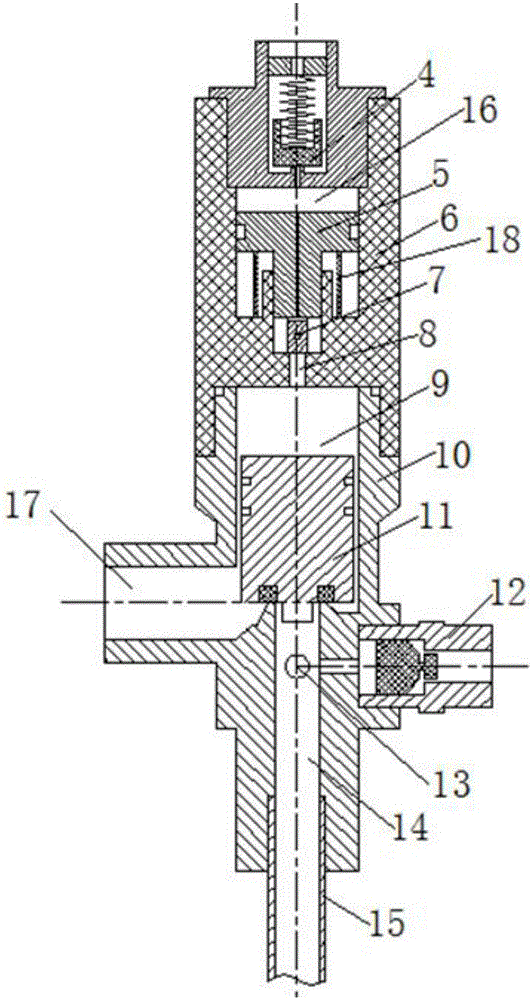

[0022] The container valve 2 includes a trigger device 6, a valve body 10 and a pressure relief device 4, the pressure relief device 4 is arranged on the upper end of the trigger device 6, and the trigger device 6 is communicated with and arranged on the upper end of the valve body 10, and the valve body The lower end of 10 is connected with the storage tank 1 of the nano-powder-based dry powder fire extinguishing agent; the trigger device 6 is triggered to connect the valve body 10 with the storage tank 1 of the nano-powder-based...

Embodiment 2

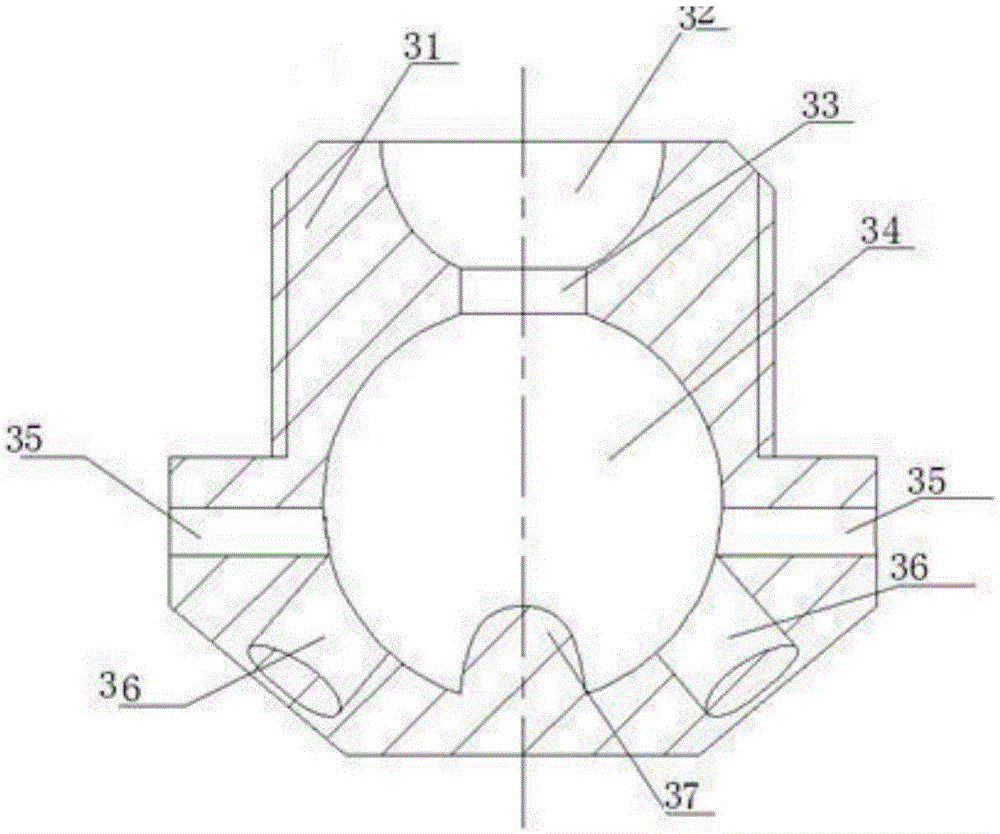

[0028] Embodiment two: if image 3 The end of the fire detection tube 3 is connected to a nozzle body 31 through a switch, and the nozzle body 31 includes a hemispherical flow channel 32, a cylindrical flow channel 33 and a spherical mixing chamber 34, and the spherical mixing chamber 34 is arranged on the nozzle body 31, the bottom of the spherical mixing chamber 34 is provided with a hemispherical pedestal 7, the hemispherical flow channel 32 is set on the upper end of the nozzle body 31, and the hemispherical flow channel 32 passes through the cylindrical flow channel 33 and the spherical The mixing chamber 34 is connected, and the size of the hemispherical flow channel 32 and the spherical mixing chamber 34 are larger than the size of the cylindrical flow channel 33; the lower end of the nozzle body 31 is provided with a number of injection holes, and the injection holes communicate with the spherical mixing chamber. Cavity 34 is connected to the outside world. The nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com