A power distribution cabinet

A cabinet frame and electrical cabinet technology, applied in the electric power field, can solve the problems of unsafe, no protective lines, inconvenient wiring, etc., and achieve the effect of convenient fixing and convenient wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

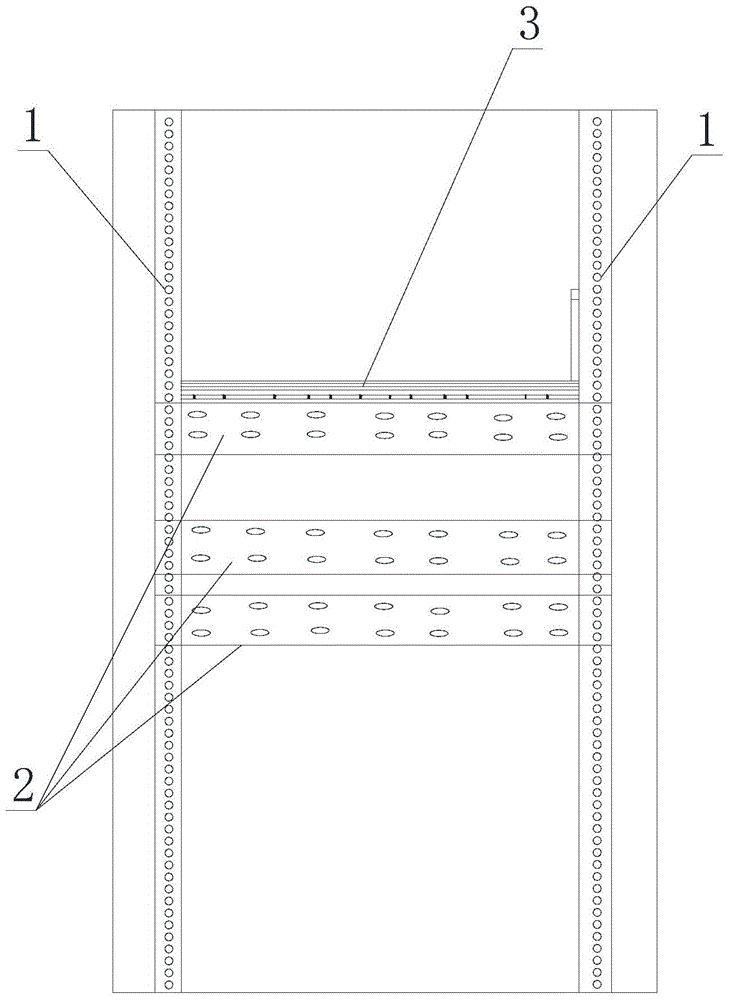

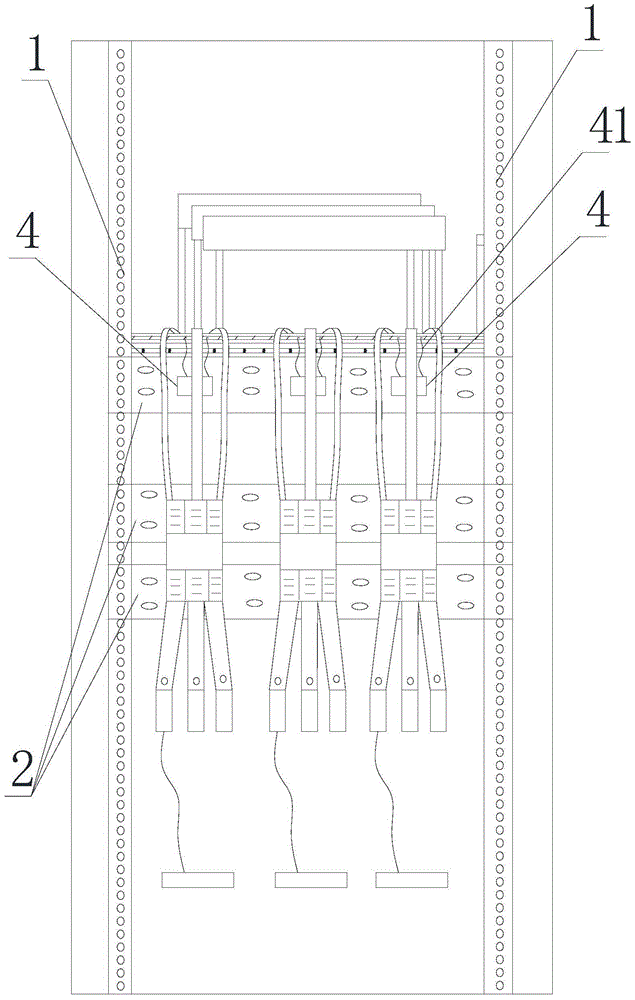

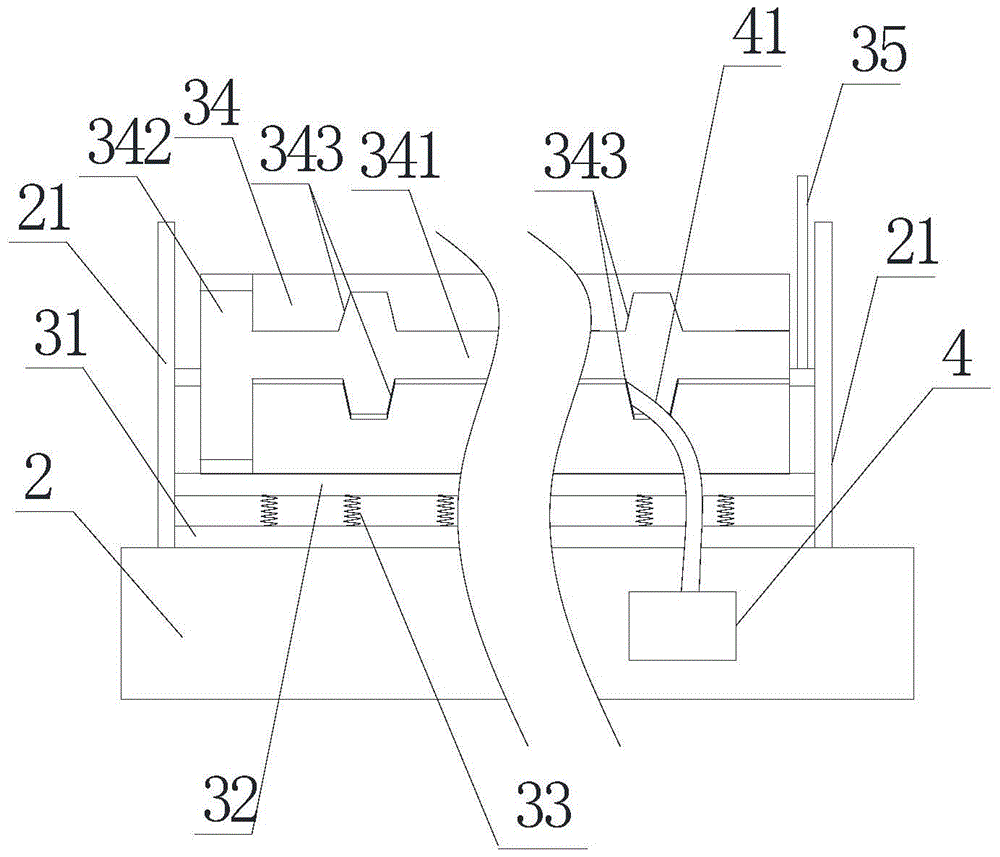

[0024] Such as Figure 1 to Figure 8 As shown, a power distribution cabinet frame of the present invention includes several longitudinal beams 1 and several cross beams 2, the longitudinal beams 1 and the cross beams 2 are connected to each other to form the main body of the electric cabinet frame, and the longitudinal beams 1 and the cross beams 2 are flexibly connected through connectors. The longitudinal beam 1 includes at least two connecting surfaces of the longitudinal beam 1 perpendicular to each other, and several longitudinal beam connecting holes are arranged in the longitudinal direction on the connecting surface of the longitudinal beam 1. Several stringer connection holes are arranged transversely on the connection surface. Such a structure is convenient to be connected and fixed with the line pipe 34, wherein at least one crossbeam 2 is provided with a fixing part 3, and the fixing part 3 includes a first horizontal plate 31 arranged on the upper end of the cross...

Embodiment 2

[0028] Such as Figure 9 , Figure 10 As shown, the difference from Embodiment 1 is that the connecting piece 21 on the side of the rotating rod 35 is provided with a movable fixing part for fixing the rotating rod 35 in the horizontal direction, and the fixing part fixes or loosens the rotating rod by moving 35. Such a structure can fix the rotating rod 35 and prevent it from disturbing to affect the stability of the overall structure. At the same time, the flat part 344 can be omitted, which simplifies the structure and increases the storage capacity of the connecting wires.

[0029] In order to prevent the connecting wire from the wire inlet 343 on the rear side of the cutout 341 moving to the wire inlet 343 on the front side of the cutout 341, the connecting wire and the fixed line part will be stuck, the wire inlet 343 on the front side of the cutout 341 is larger than the cutout 341 The wire inlet 343 on the rear side.

[0030] By implementing the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com