Capacitor core package lead puncture stripping assembly and its working method

A capacitor and stripping technology, used in capacitors, capacitor manufacturing, electrical components, etc., can solve problems such as narrow application fields, and achieve the effect of reasonable structure, simple and reasonable structure, and easy to fit closely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

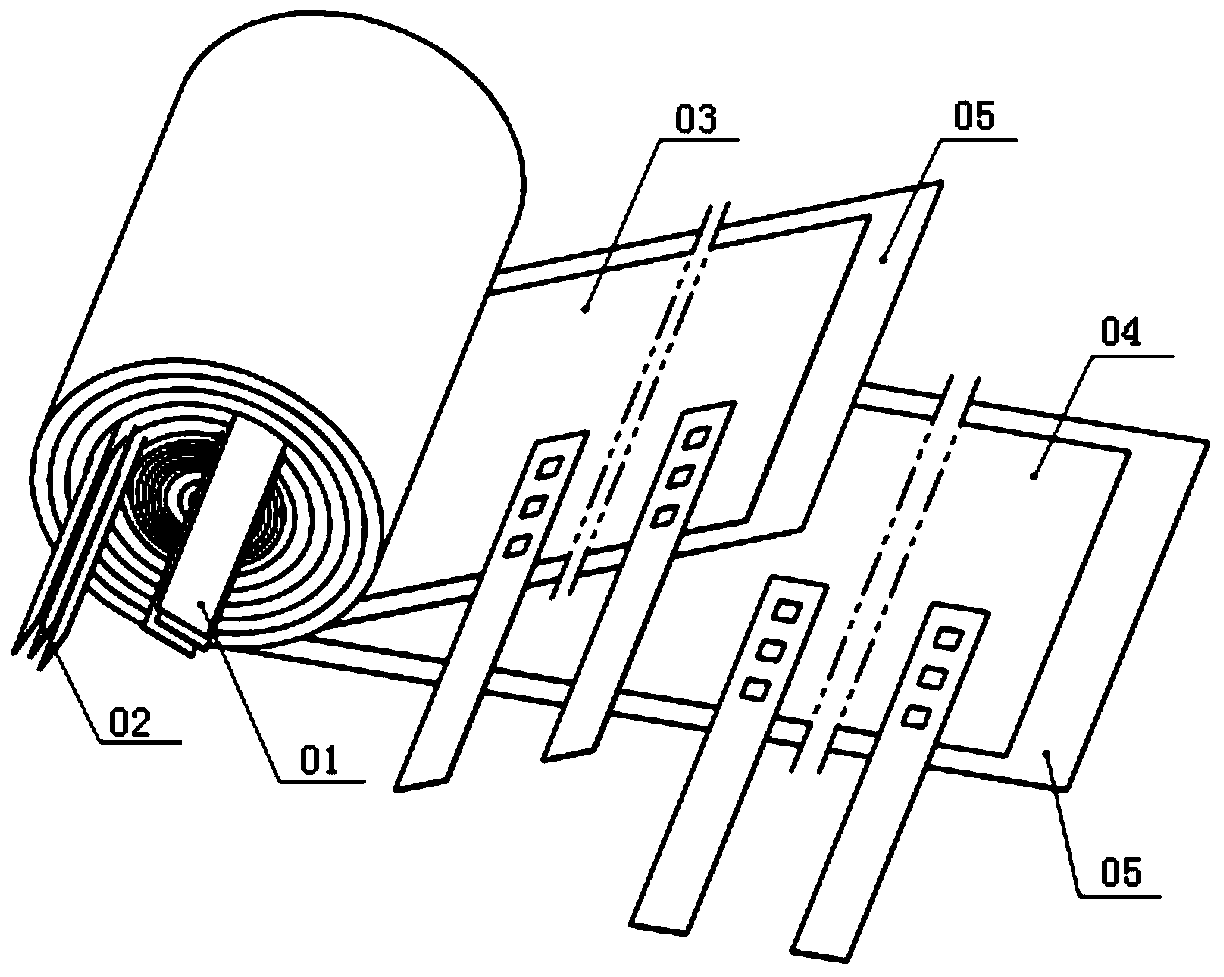

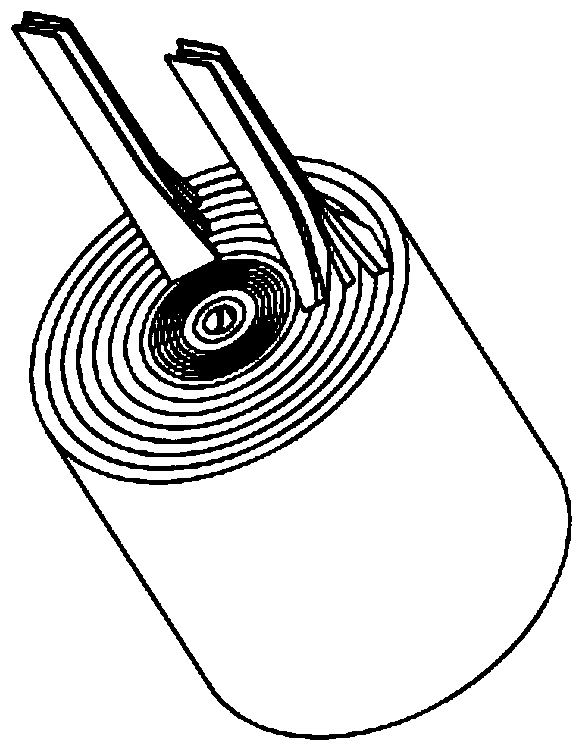

[0033] The capacitor core package is composed of electrode foil, electrolytic paper and two pins, which are divided into anode 01 and cathode 02. The capacitor core is wrapped in the electrode foil and electrolytic paper winding process, the aluminum foil is nailed to the corresponding electrode foil according to the anode foil 03 and the cathode foil 04 respectively, and the electrode foil and the electrolytic paper 05 are wound and stacked together to form Core-wrapped pins, the number of layers is generally 3 to 8 layers, the winding process is as follows figure 1 shown. Due to errors in the production process, it is difficult to ensure that the multi-layer aluminum foil is stacked neatly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com