Long service life light-emitting unit for LED lamp

A technology of LED lights and light-emitting units, which is applied in the field of long-life LED light-emitting units, can solve problems such as disconnection of electrical contacts, arc ignition, etc., and achieve the effects of avoiding disconnection, prolonging life, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

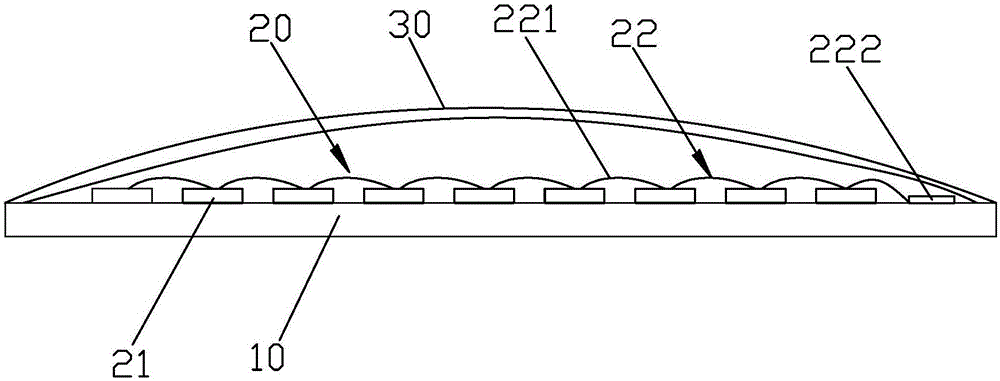

[0044] Please check figure 1 , a long-life LED lamp light-emitting unit, including a substrate 10 , a LED bare die part 20 and a fluorescent glue part 30 . The LED die portion 20 includes a plurality of LED die 21 and a circuit portion 22 electrically connected to the plurality of LED die 21 . The LED die 21 is fixed on the substrate 10 , and the substrate 10 and the fluorescent glue portion 20 are relatively fixed. . The plurality of LED bare die 20 emit blue light after being energized, and the blue light is converted into white light by the fluorescent glue part 20 and then irradiated to the outside. Of course, it can also be other colors. The fluorescent glue part 30 includes fluorescent powder and glue, and the glue and the fluorescent powder are mixed.

[0045] The substrate 10 is, for example, a transparent plate or an opaque plate. If the transparent plate is a glass plate, the front or back of the glass plate is coated with a reflective agent to form a reflective s...

Embodiment 2

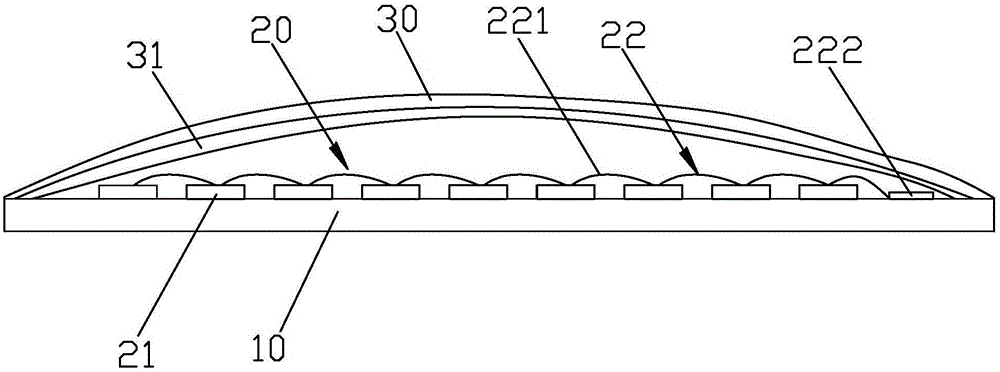

[0052] Please check figure 2 , it differs from the first embodiment in that: the fluorescent glue part layer 30 is coated on the inner surface or the outer surface of the lampshade 31 , and the lampshade 31 covers the LED bare die part 20 inside.

Embodiment 3

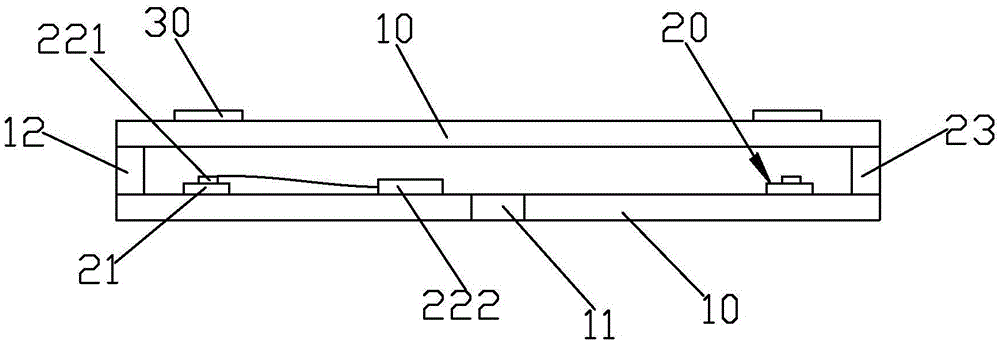

[0054] It differs from Embodiments 1 and 2 in that the above-mentioned circuit part is printed on the substrate for fixing the bare die to form a circuit board, that is, the above-mentioned bonding wire 221 and the joint part 222 are directly printed on the substrate, and the LED is bare. The crystal is fixed on the substrate, that is, it is electrically connected to the circuit part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com