Carrying welding robot planet cycloid decelerator

A cycloid reducer, welding robot technology, applied in mechanical equipment, gear transmission, belt/chain/gear and other directions, can solve the problem of how to adjust the phase of the epicycloid wheel is not clearly explained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

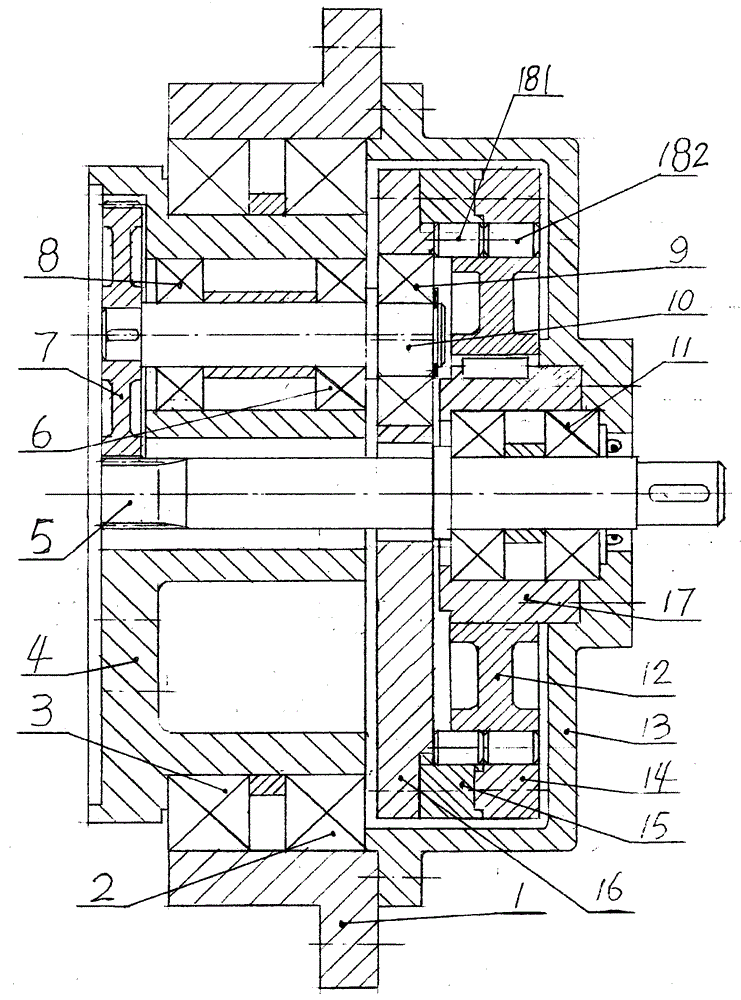

[0025] Such as figure 1 As shown, a planetary cycloidal reducer for a welding robot includes a housing 1, first and second bearings 2, 3, an output disc 4, a bearing seat 17, a large end cover 13, a planetary transmission part and a cycloidal transmission part, It is characterized by:

[0026] The inner hole of the housing 1 supports the rigid output cylinder 4 with the first and second bearings 2 and 3, the round end surface of the housing 1 is connected with a large end cover 13, and the inner hole of the large end cover 13 is connected with a bearing seat 17;

[0027] Described planetary gear comprises sun gear 5, three evenly distributed planetary gears 7 and three evenly distributed crankshafts 10, and described crankshaft 10

[0028] The third and fourth bearings 6, 8 are supported in the corresponding holes of the rigid output cylinder 4, the planetary gear 7 is connected to one side shaft head of the crankshaft 10, and the fifth bearing 9 is installed on the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com