Variable-frequency multipath pulsating flow generation device

A generating device and pulsating flow technology, which is applied to fluid pressure actuating devices, fluid pressure actuating system components, mechanical equipment, etc., can solve the problems of non-superposition and non-multiplexing of pulsating flow, and achieve simple structure and easy maintenance. Easy, practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

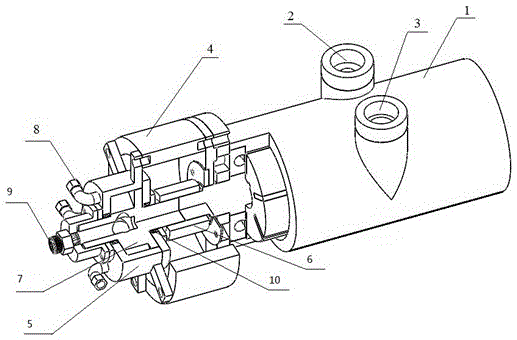

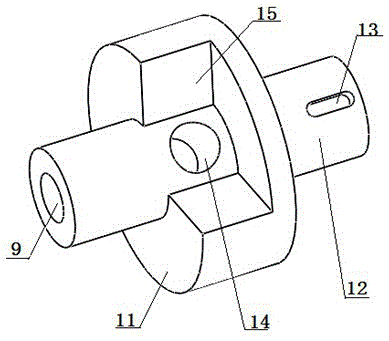

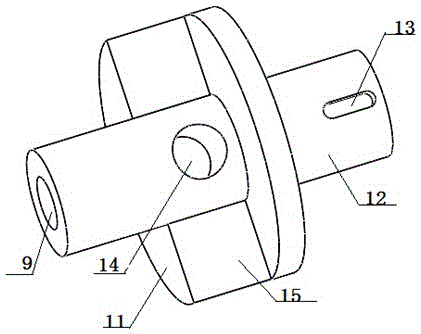

[0024] Embodiment 1: as Figure 1-7 As shown, a variable frequency multi-channel pulsating flow generating device includes a motor 1, a connecting body 4, a half-shaft valve body 5, a sleeve 6, a half-shaft valve core 7, and an end cover 10; the half-shaft valve body 5 passes through the connecting body 4 Installed on the motor 1, the half-shaft valve core 7 is installed in the half-shaft valve body 5, the end cover 10 is installed on one end of the half-shaft valve body 5, and the other end of the half-shaft valve core 7 is connected with the motor 1 through the sleeve 6. The half shaft spool 7 includes a cylinder 11 and a shaft 12; the cylinder 11 is placed in the middle of the shaft 12, the left part of the shaft 12 is a hollow shaft, the right part of the shaft 12 is a solid shaft and a keyway 13 is provided on it, and the hollow shaft 12 The shaft hollow is the inlet port 9 of the half shaft valve body, the middle part of the shaft 12 is provided with the outlet port 14 o...

Embodiment 2

[0026] Embodiment 2: as Figure 1-7 As shown, a variable frequency multi-channel pulsating flow generating device includes a motor 1, a connecting body 4, a half-shaft valve body 5, a sleeve 6, a half-shaft valve core 7, and an end cover 10; the half-shaft valve body 5 passes through the connecting body 4 Installed on the motor 1, the half-shaft valve core 7 is installed in the half-shaft valve body 5, the end cover 10 is installed on one end of the half-shaft valve body 5, and the other end of the half-shaft valve core 7 is connected with the motor 1 through the sleeve 6. The half shaft spool 7 includes a cylinder 11 and a shaft 12; the cylinder 11 is placed in the middle of the shaft 12, the left part of the shaft 12 is a hollow shaft, the right part of the shaft 12 is a solid shaft and a keyway 13 is provided on it, and the hollow shaft 12 The shaft hollow is the inlet port 9 of the half shaft valve body, the middle part of the shaft 12 is provided with the outlet port 14 o...

Embodiment 3

[0028] Embodiment 3: as Figure 1-7 As shown, a variable frequency multi-channel pulsating flow generating device includes a motor 1, a connecting body 4, a half-shaft valve body 5, a sleeve 6, a half-shaft valve core 7, and an end cover 10; the half-shaft valve body 5 passes through the connecting body 4 Installed on the motor 1, the half-shaft spool 7 is installed in the half-shaft valve body 5, the end cover 10 is installed on one end of the half-shaft valve body 5, and the other end of the half-shaft spool 7 is connected to the motor 1 through the sleeve 6. The half shaft spool 7 includes a cylinder 11 and a shaft 12; the cylinder 11 is placed in the middle of the shaft 12, the left part of the shaft 12 is a hollow shaft, the right part of the shaft 12 is a solid shaft and a keyway 13 is provided on it, and the hollow shaft 12 The shaft hollow is the inlet port 9 of the half shaft valve body, the middle part of the shaft 12 is provided with the outlet port 14 of the half s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com